Making Soup

Find innovative production technology for making soup liquids and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Processing steps involved in soup liquids making

Which soup liquids technology do you need?

Aseptic bag-in-box filler for laboratory use

Achieve aseptic filling precision on a lab-scale with a compact solution that...

Batch deaerator for reduced oxidation in liquid processing

Optimize product shelf life and quality by efficiently removi...

Gravimetric filling and capping system for chlorine solutions

Optimize your filling and capping processes for chlorinate...

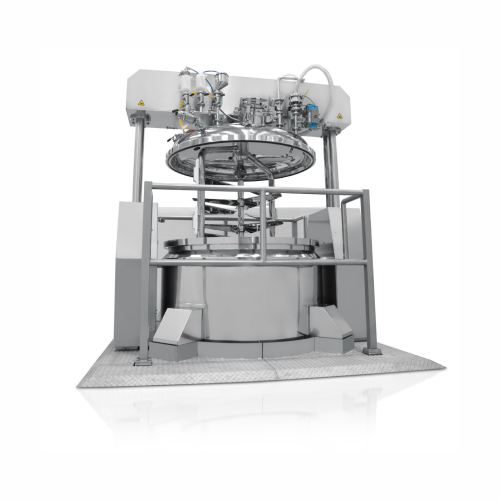

Vacuum turboemulsifiers for liquid and creamy products

Simplify your production workflow with high-capacity vacuum turboe...

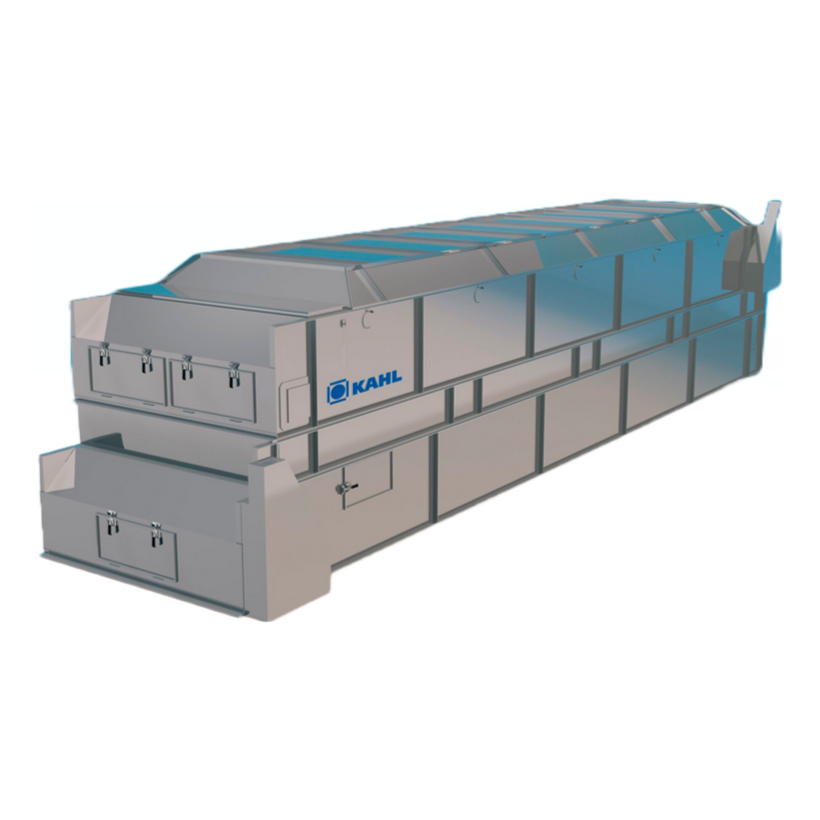

High-capacity pouch cooling system

Move pouched foods swiftly through critical temperature zones, ensuring rapid cooling fo...

Industrial aseptic fillers for food processing

Ensure sterile packaging with advanced aseptic fillers, designed for precis...

Sterilizer for liquid and viscous products

Effortlessly process and sterilize diverse liquid products, from concentrated j...

Manual filling system for bag-in-box packaging

Streamline your liquid filling process with a manual system designed for pr...

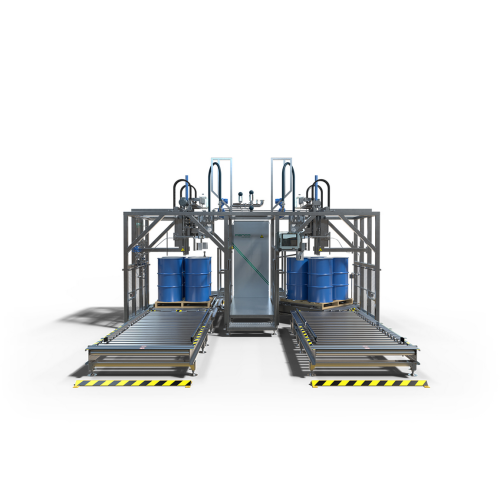

Bag-in-box filler with dual heads and automatic features

Boost your liquid production efficiency with a dual-head filling...

Automatic volumetric filler for liquid products

Optimize your production with this high-precision volumetric filler, desig...

Liquid capsule filling for r&d and pilot-scale production

Optimize liquid capsule production with a compact machine that...

Aseptic filler for juices and beverages

Ensure sterile packaging with precision. This aseptic filler offers high-speed, con...

Ultraclean filling monoblocks for food industry

Enhance product safety and quality with monoblocks designed for ultraclean...

X-ray scanner for sealed container inspection

Ensure the integrity and quality of sealed containers while seamlessly integ...

Fully automatic filling lines for liquids

Achieve precise dosing and filling of liquids with minimal cycle times using com...

Compact aseptic filling solution for versatile production

Maximize production line efficiency with a compact filling sys...

Aseptic filling solution for liquid food packaging

Optimize liquid food production with advanced aseptic filling, ensurin...

Pneumatic syringe dosing system

Streamline your liquid dosing process with precision and efficiency, ensuring each applicati...

Multifunction case packer for bottles and jars

New ways of packaging products are popping up all the time on the market. T...

Shrink wrapping machine for PET bottles

During a shrink-wrapping process, a change of reel can slow down the production cyc...

Wrap-around case packer for cans or bottles

When it comes to beer packaging, most of the manufacturers use plain box carto...

Medium scale round can seamer

Automatic seaming of cans of craft bear can be quite the hassle with the movement from the cen...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

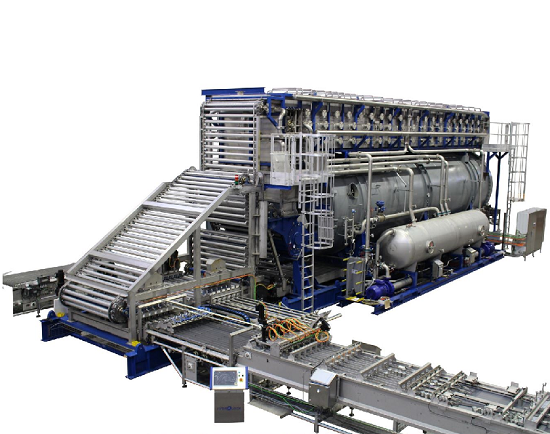

Continuous sterilizer for canned products

Sterilization is a critical operation in the manufacturing of canned vegetables ...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the pac...

HFFS machine with servo-control system

Traditional HFFS machines use mechanical cams to drive the production path through t...

High Speed Premade Pouch Packaging Machine

Pre-made pouches can be problematic for traditional cam-driven mechanical HFS m...

Autoclave for doypack pouches

The self-standing Doypack and other similar pouch products are a very popular method of packag...

Can seamer for food products

Flexible can seaming equipment is required to adapt for product-specific variations in food can...

Industrial vegetable cutter

Retaining freshness in cut vegetables, as well as retaining vitamins and nutrients, is a top pri...