Making Instant Noodles

Find innovative production technology for making instant noodles and connect directly with world-leading specialists

Noodles comprise as much as 50% of all the processed wheat consumed in Asia. But the chewy, stringy meal is not only a staple in Asian countries. Instant noodles are a popular meal for many people on the go. Instant noodle making equipment produces miles of strands daily, ready to come to life with a dash of boiling water.

Tell us about your production challenge

Stretch the dough into a sheet to make noodles

The traditional ingredient in instant noodles is wheat flour. Other gluten-free products use rice or Kamut. Mix the flour with water and salt in a kneader until it combines into the unleavened dough.

The secret to perfect noodles is to develop the dough into a flat mass. Pass it through a roller machine to stretch it into a thin sheet. An alternative method is to form a continuous leaf with an extrusion machine.

Use specialized instant noodle cutting technology for a homogeneous size

Straight, wavy, or curly instant noodles come in various shapes and sizes depending on their intended dish. A regular thickness is 1.5mm in width, but sizes range from 2.5mm (very thick) to 1.0mm (very thin).

Move the dough into the cutting unit, where a rolling blade forms the fresh sheet into strands of precisely-cut noodles.

Instant noodles are par-cooked by steaming

The next process for the noodles is steaming. The high-temperature vapor partially cooks the dough as it passes through the steam chamber.

Once steamed, the noodles are ready for seasoning. A system of nozzles sprinkles the dough with the prepared mix according to the recipe. At this point, the par-cooked noodles still form a long strand of dough.

Fry the noodles to form the package-ready product

Use a knife system to cut the noodle mass into exact portions and deposit them in molds. These go through a fryer to combine the seasoning into the dough.

The frying process also compacts the portion into a rigid, if brittle, mass. Lead the instant noodles into a cooling tunnel to reduce the heat absorbed during frying. The noodles are ready to be packaged and shipped out.

Which instant noodles technology do you need?

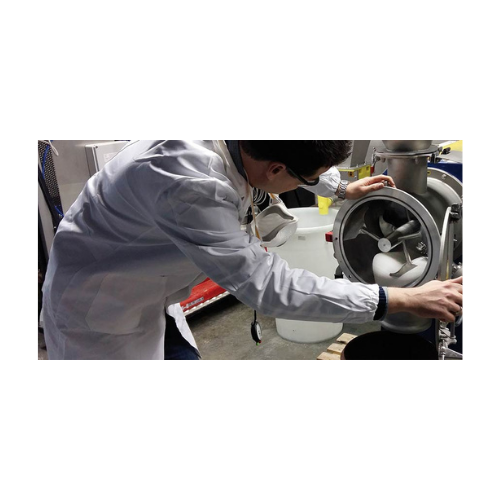

Commercial food drum mixer for sauerkraut and salads

Streamline your batch production with this versatile commercial food...

Industrial snack food fryer

Achieve precise temperature and conveyor speed control for consistently uniform snacks with this...

Grain separator for impurity removal in milling

Optimize grain cleaning with a high-performance separator designed to effi...

Industrial steaming unit for noodles

Achieve precise noodle texture and uniform gelatinization in continuous high-speed ope...

Dough ripening conveyor for stick and fried noodles

Ensure optimal dough maturity and consistency with this conveyor, des...

Continuous dough rolling unit for noodles

Ensure your noodle production maintains consistent quality with precise dough th...

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

Laboratory plansifter for grain milling and brewing

Achieve precise particle-size distribution and quality control across...

Compound rolling unit for dough sheets

Achieve unparalleled precision in dough formation with our high-speed compound rolli...

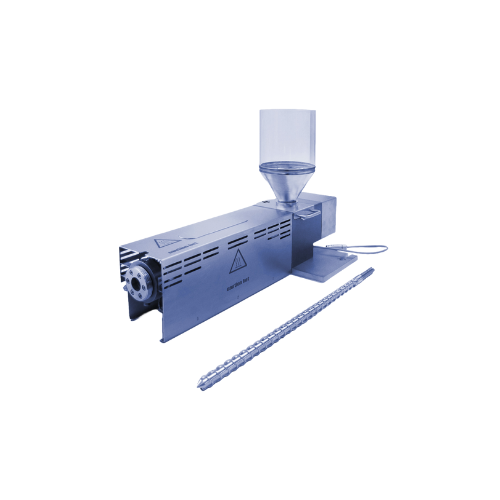

Polymer testing extruder

Effortlessly evaluate polymer and plastic product properties with precision, ensuring your materials...

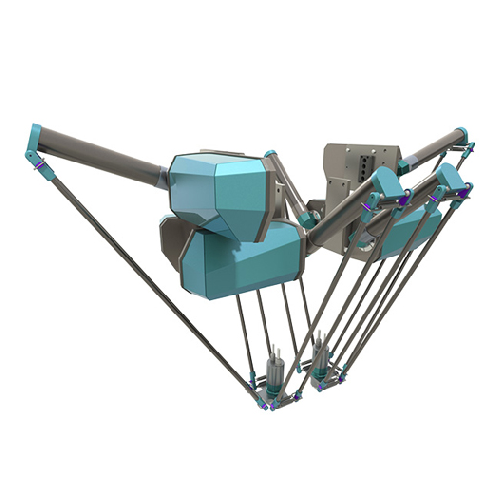

Dual-axis delta robot for high-capacity packaging lines

Enhance your production line’s efficiency with a dual-axis ...

Industrial cooling system for packaging temperature control

Achieve precise temperature control and maximize energy effi...

Industrial water cooker for pasta processing

Enhance your pasta production with precise water cooking, ensuring consistent...

Single-screw cooking extruder for high-value food products

Transform raw materials into diverse, high-value products wit...

Single-screw extruder for pre-gelatinized materials

Streamline your production of snack pellets and instant noodles with ...

Atex-certified flanged polygonal dust collectors

Ensure dust control and compliance in explosive environments with our com...

Industrial dust collection system for air filtration

Optimize air quality in your production line with this compact dust ...

Atex certified flanged round dust collectors

Designed for potentially explosive environments, these flanged round dust col...

Fit-frame butterfly valves for dry bulk solids

Achieve precise control and minimize contamination in your dry bulk materia...

Low profile slide valve for controlling powder flow

Optimize your powder and granule flow management with precision-engin...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Vibro-aerators for bulk solids discharging

Optimize your powder flow and ensure consistent discharge with this advanced ae...

Silo overfill protection valves

When abnormal pressure threatens your silo’s integrity, reliable pressure relief becom...

Drop-through rotary valve for powder and granular material feeding

Achieve precise control in discharging and feeding p...

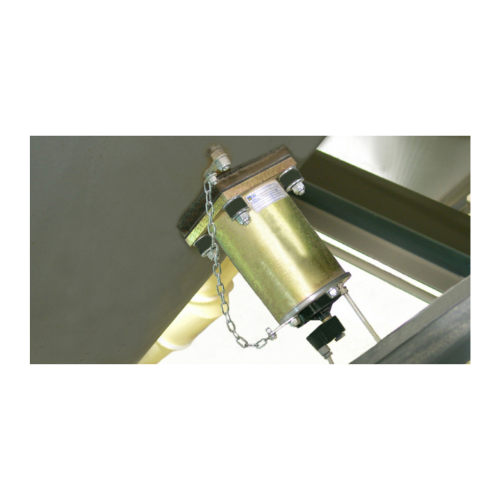

Single impact pneumatic hammers for flow aids

Combat material clogs and ensure smooth flow in your production line with pn...

Industrial vibrator for high-frequency vibration

Achieve efficient material flow and compaction across various production ...

Rotary turbine vibrators for material flow aid

Optimize your production efficiency with high-speed, silent operation vibra...

Continuous impact vibrators for bulk material removal

Combat material flow issues like bridging and rat-holing with our i...

External electric motovibrators for industrial material flow

Experience enhanced material flow and precise material disc...

Silo overfill protection system

Prevent silo overfilling and excess pressurization with a system designed to safeguard silos...

Laboratory batch mixer for small scale production

Achieve rapid and reproducible mixing results with this laboratory batc...

Bin level indicators for wastewater treatment

Ensure reliable material level monitoring in your silos and hoppers with ILT...

Electronic pressure meters for silo safety monitoring

Ensure precise pressure management in your systems with this advanc...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Hopper venting filter for efficient dust filtration

Achieve superior dust control and efficient material handling with a ...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Vibratory outlet hopper for bulk material discharge

Struggling with material bridging and inconsistent discharge? Enhance...

Food-grade bin activator for optimized material flow

Ensure hygienic and efficient discharge from hoppers with our food-g...

Food-grade bin activator for hygienic bulk solids discharge

Achieve consistent material flow and avoid contamination wit...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...

Automatic noodle maker for diverse noodle shapes

Streamline your noodle production with a machine that crafts a variety of...

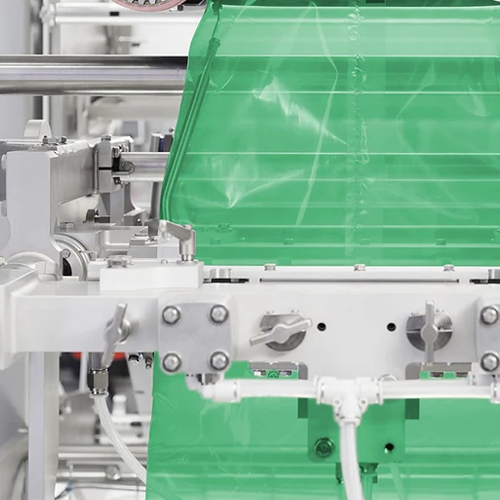

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

In-line metal detector for liquids & pastes

Ensure product safety by seamlessly integrating a metal detection system into ...

Conveyor belt metal detection system

Ensure seamless product safety with a system that detects and separates metallic conta...

Metal detector systems for conveyor belts and chutes

Ensure the integrity of your production line by efficiently detectin...

Top load Case Packer For Food Products

If you want to pack your food cartons, doy packs and pouches into regular cases, a s...