Making Vegetable Chips

Find innovative production technology for making vegetable chips and connect directly with world-leading specialists

From cassava to sweet potatoes, various types of vegetables are processed to make one mixed bag of vegetable chips. Mainly consisting root vegetables like taro and parsnip, vegetable chips are often introduced as a healthy alternative to potato chips. To make these chips, you first need to slice the vegetables and cook them depending on your product; you can simply bake them or fry them, deep fry them, or dry them. After this process, flavorings are added to the chips.

Stories about vegetable chips

Select your vegetable chips process

Tell us about your production challenge

Set up your vegetable chips production line

Making vegetable chips is quite similar to making potato chips. First, those vegetables need to be washed in a drum washer and dried off. Then, their skin is removed in a peeler and sliced in a vegetable cutter – a rotary continuous cutting device is often chosen for vegetable chips. At this point, the production line is a bit different from potato chips as the vegetables will not be soaked in the water like the potato chips. Root vegetables like beet and carrots contain relatively less amount of scratch, and they do not need an additional process to remove the starch like potatoes.

After the raw vegetables are all prepared to be cooked, you can choose your method of cooking among frying, baking, or dehydrating (drying). For frying, the most common choice of technology is the vacuum fryer, and for baking, it is a convection oven. For dehydrating or drying, producers often choose drying cabinets or triple-pass dryers. Still, the vacuum fryer method is the most popular choice for manufacturing veggie chips since it can recreate the crunchiness of potato chips. If you baked or fried the veggie chips, you also need to cool them in the air dryer or air cooling machine.

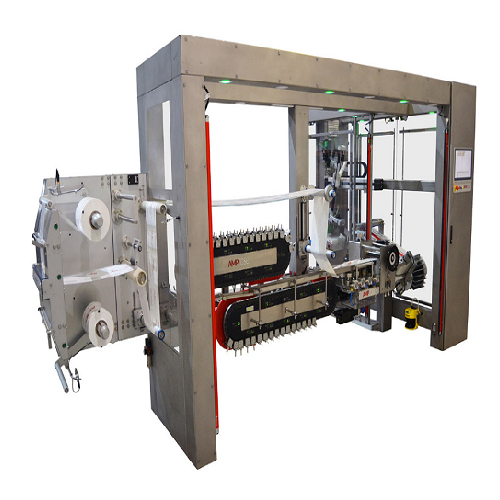

You can always add flavorings such as seasoning, herbs, spices, cheeses, and artificial additives to the cooked chips. This can be done in the drum coaster, where the cylinder drum is circulated continuously, mixing the materials thoroughly without any residue. Finally, these chips are ready to be packed in bags and pouches through the bagging machine.

Frying, baking, or drying, that is the question!

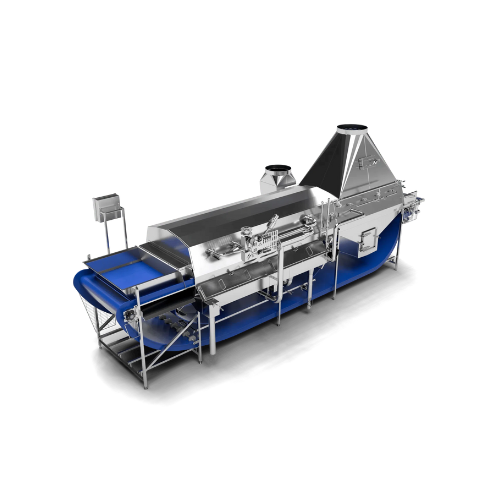

Among the three cooking methods – frying, baking, and drying – frying through a vacuum fryer are most commonly adopted. Vacuum fryer technology is a relatively new technology that developed a new way of frying at low pressure and temperature. Hence, compared to atmospheric deep frying, vacuum frying can enhance the color, taste, and general quality. It can also absorb less amount of oil compared to the traditional frying method, allowing them to be a healthier processing method.

As an alternative to vacuum frying, producers can also choose to bake the veggie chips. A convection oven can draw the moisture out of the vegetables in the most efficient way. By controlling the airspeed, you can ultimately control the color of the chips and the baking process – the higher the airspeed is, the faster the moisture can leave the vegetable. However, using a convection oven can be quite tricky. Since the vegetable chips are thin, the baking time has to be really short in the oven – even under one minute. Also, the moisture has to be drawn out evenly without burning the chips. Hence, this manual control factor can act both as an advantage and a drawback.

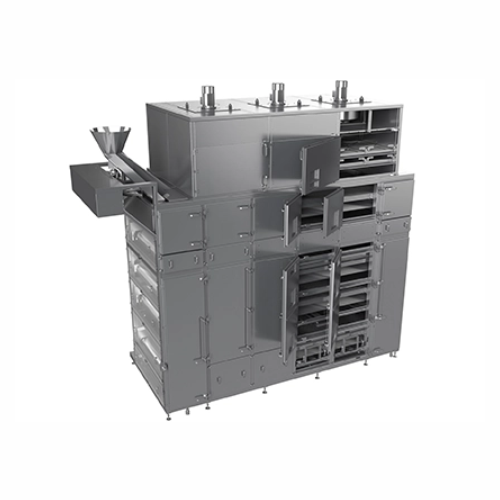

Lastly, you can also dry the vegetable if you are intending to produce the most “healthy” and least fatty chips. A dehumidification cabinet, or drying cabinet, can be used for this process. In the cabinet, heated air flow constantly circulates through the space, which can evenly dry the vegetables inside. This method can preserve the vitamins and taste of the vegetables, even if the crunchy mouthfeel might not be present in these chips. Another equipment option for drying is triple-pass driers. This machine particularly specializes in drying thin slices of vegetables, as it moves the chips around many times from one belt to another to achieve even color and drying.

Making a healthy and delicious veggie chip – lower the temperature!

Generally, the goal of making veggie chips is to make a healthy alternative to potato chips. Hence, the prioritized factor in producing veggie chips is making them as healthy and delicious as possible. By adjusting the frying temperature of your chips, you can reduce the risk of causing cancer; lowering the frying or baking temperature can decrease the formation of acrylamide, which can cause cancer when one continuously consumes a large amount of it. Also, as a side benefit, this lowering of temperature can improve the color of the chips, making them look more appetizing.

Processing steps involved in vegetable chips making

Which vegetable chips technology do you need?

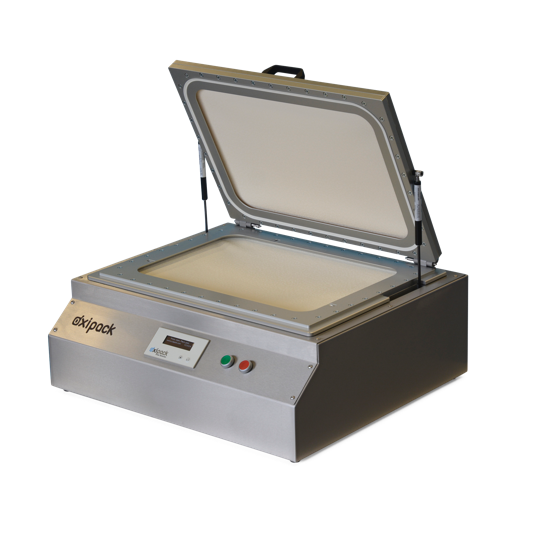

Vacuum packaging system for food products

Optimize your packaging process with high-speed vacuum technology designed to pr...

Large insulated oil storage tank

Ensure optimal temperature control for sensitive liquids like oils, sauces, and creams with...

Vegetable and fruit cutting solution for slices, segments, and sticks

Streamline your pre-processing with a versatile c...

Packaging solution for bulk vegetables and fruits

Ensure precise, high-speed packaging for diverse product sizes with a f...

Washing and grinding system for fruit and vegetables

Efficiently wash and grind fruits and vegetables to streamline your ...

Industrial fruit drying cabinet

Efficiently transform fresh produce into long-lasting, nutrient-dense snacks with precise dr...

Industrial cutting solution for potato products

Optimize your potato and vegetable processing with a versatile cutting mac...

Heavy-duty batch fryer for snack and prepared foods

Effortlessly transform diverse ingredients into high-quality fried pr...

Potato slice washer conditioner

Ensure consistent texture and color in your potato chips by precisely controlling washing an...

Electroporation system for potato products

Optimize your potato and snack food production with an electroporation system t...

Industrial water removal system for food preparation

Enhance your production line with advanced surface water and starch ...

Continuous belt dryer for large-scale drying applications

Optimize your production with a continuous belt dryer, enginee...

Vegetable and fruit dicer

Achieve uniform cuts and reduce waste in your food processing line with a versatile dicer designed...

Flat-belt slicer for fruits and vegetables

Optimize your slicing process with a solution that delivers precision cuts whil...

Vegetable and fruit centrifugal slicer and shredder

Enhance your food processing with high-capacity slicing and shredding...

Pulsed electric field treatment for roots, tubers, and fruits

Enhance your production line with advanced pulsed electric...

Precision quality control for potato and vegetable cutting

Optimize cutting precision and improve product quality by ins...

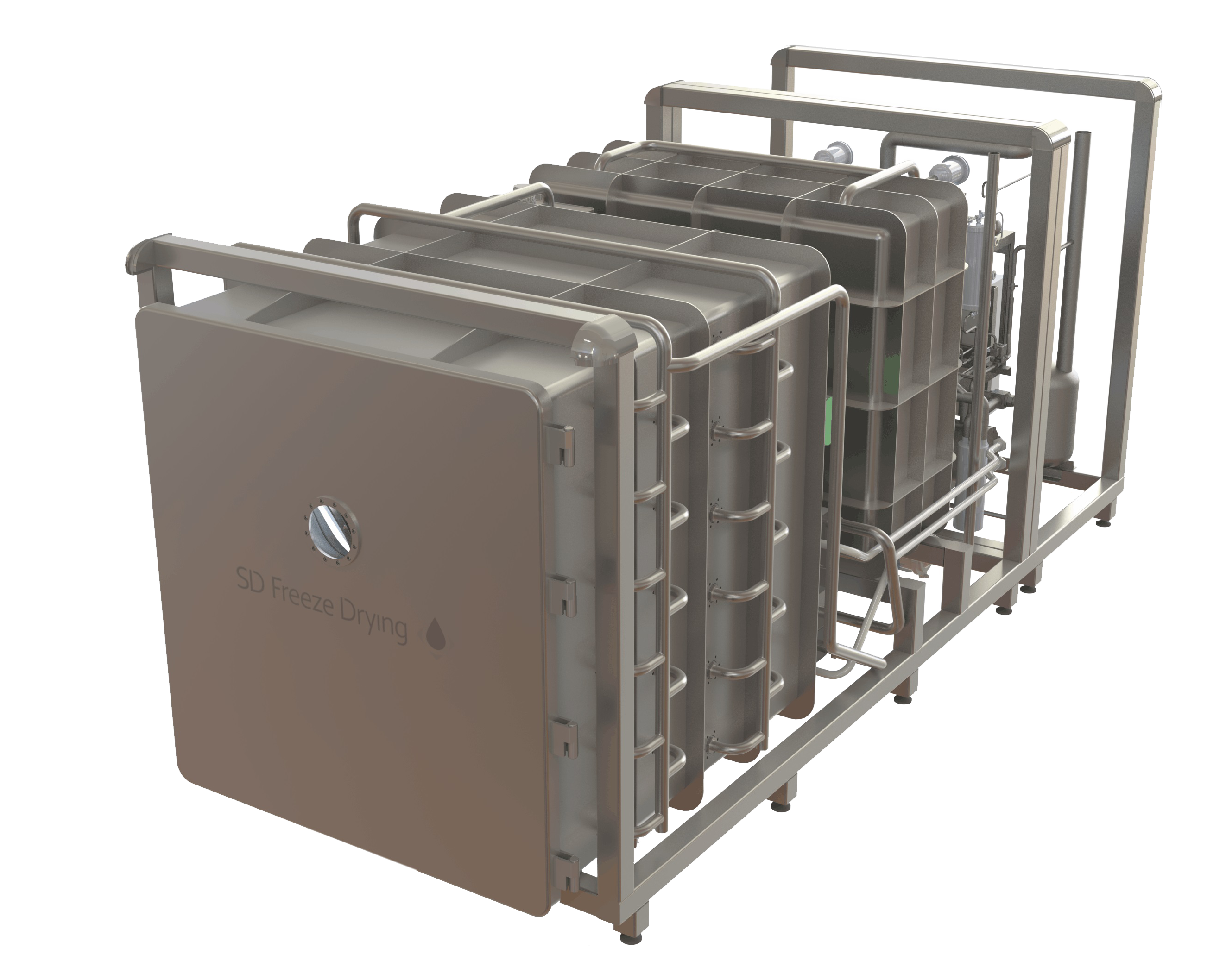

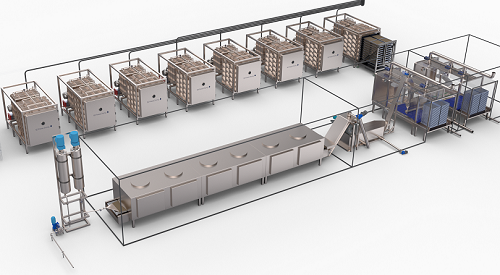

Freeze dryer for high sugar or acid content products

Achieve precise moisture control for challenging high sugar or acid ...

Industrial freeze dryer for large scale food processing

Optimize moisture removal for high-quality food preservation and ...

Leaf vegetable sorting and cooling system

Ensure optimal freshness and extended shelf life for leaf vegetables with precis...

Evaporative blancher for fruits and vegetables

Achieve significant water savings and reduce wastewater generation in your ...

High-efficiency cooling tunnel for confectionery production

Optimize your product cooling process with high-efficiency t...

Vibrating tables for dewatering and sizing

Optimize your processing line with versatile vibrating tables designed to effic...

Drum blancher for continuous cooking and blanching

Optimize your production line with a continuous drum blancher, designe...

Hydro-extractor for vegetable water removal

Efficiently remove excess moisture from vegetables and pre-processed ingredien...

Multipack flowrapping system

Streamline your packaging process with a multipack flowrapping system that effortlessly handles...

Sweet pepper decorer

Streamline your sweet pepper processing with a high-speed solution that efficiently removes cores, clean...

Water cooker for fresh pasta processing

Enhance cooking precision and product quality with this water cooker, designed to c...

Liquid nitrogen freezer for sensitive food and fermentation ingredients

Achieve rapid, uniform freezing of sensitive fo...

Industrial multifiller for fruit and vegetable salads

Need to efficiently fill diverse containers with fruit and vegetabl...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Compact food dehydrator with Bpa-free trays

Achieve precise dehydration with compact, kitchen-friendly equipment, perfect ...

Compact food dehydrator for fruits and meats

Achieve precise dehydration of fruits, vegetables, and meats with a compact s...

Food dehydrator with Bpa-free plastic trays

Achieve precise dehydration for fruits, vegetables, and snacks with advanced t...

Food dehydrator with stainless steel trays

Achieve optimal dehydration with precise temperature control and efficient dual...

Professional food dehydrator for fruits and vegetables

Enhance your culinary creations with precise dehydration technolog...

Multi-function vegetable cutting machine

Effortlessly transform a variety of fruits and vegetables into precise shapes and ...

Fast vegetable dicing solution for food processing plant

Efficiently transform root vegetables and fruits into uniformly ...

Small vegetable food dehydrator

Efficiently remove moisture from your fruits and vegetables with this centrifugal dehydrator...

Small scale potato chips production line

Optimize your small-scale snack production with a versatile solution that seamless...

Small banana slicer for chips

Efficiently transform diverse root vegetables into uniform, smooth slices, ensuring minimal fi...

Portable texture analysis for low force applications

Easily perform precision texture measurements on low-force applicati...

Semi-automatic fruit and vegetable slicer

Optimize your fruit and vegetable processing with precise cutting capabilities, ...

Leak tester for pouches and MAP packaging

Nuts are packed with unsaturated fatty acids, which means they are prone to oxid...

Industrial potato washer

Washing potatoes or other vegetables can be a time consuming task for large restaurants or other foo...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Industrial food freeze dryer

Nutraceuticals and dietary supplements can be highly sensitive and need to be protected against...

Automatic freeze drying system

Freeze drying can be an expensive and cumbersome process. When dealing with nutraceuticals it...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...