Making Rice Cakes

Find innovative production technology for making rice cakes and connect directly with world-leading specialists

Rice cakes are a versatile, low-calorie, fiber-rich food consumed in many cultures either as a dish, like in Asian countries or as a healthy snack. Rice cake production and properties come in a wide range of varieties, and it’s important to have rice cake making equipment that can accommodate the manufacturing of all of them.

Select your rice cakes process

Tell us about your production challenge

Getting the right consistency: equipment and processes for rice cake making

Rice cake makers start the production process by soaking either white or brown rice. After that, they transfer the softened rice into a preheated hooper of the popping machine where they press and puff the rice. There is a sudden release of water vapor at this stage, which causes the puffed rice to clump together to form rice cakes. After that, they transport the puffed rice cakes through a conveyor belt to a spray where salt and extra flavors like strawberries are added using rotating drums. Producers ensure they produce rice cakes with the right consistency by ensuring the rice is subjected to a high temperature of about 200-230⁰C and pressure of 1.3-1.5MPa for 75-85 seconds in the rice cake machine. They further confirm the texture by performing a texture analysis using a texture analyzer.

White rice versus brown rice: which is better?

The major ingredient in any rice cake production line is, as you would imagine, rice which is either white or brown. Generally, brown rice contains many valuable nutrients and offers outstanding benefits, unlike white rice, which has all its nutrients stripped off during processing.

Using brown rice-derived rice cakes is richer and more nutritional. Their outer layer, which is still intact, has a high fiber content, which is beneficial in lowering cholesterol levels and preventing cardiovascular diseases likes strokes and heart attacks. They are rich in phytochemicals, that function as antioxidants to help the body fight against cancers.

In addition, they contain a lot of essential vitamins, like vitamin E, and micronutrients like iron, copper, zinc, and magnesium. Whole grains like brown rice also have improved gut health and limit the risk of developing chronic diseases like type 2 diabetes and hypertension.

Given all these benefits, consumers must be able to identify and purchase rice cakes made from whole grains. To make this easy, producers write whole grain as the first ingredient and include the carbohydrate-to-fiber ratio which the U.S Department of Agriculture (USDA), for example, recommends should be less than 10:1. Note that the qualification for whole grain foods differ per country in the European Union. In Netherlands, foods must contain 100% whole grain to be labeled as such, while Germany requires at least 90%.

Coating options for rice cakes

Rice cakes are generally considered healthy because of their low glycemic index and high fiber content. However, manufacturers enhance their flavor to make it more appealing by coating them with various products. Chocolates and yogurts are the most common coatings but lard and cinnamon are alternative coatings that can naturally improve the taste of rice cakes. Although these coatings might potentially increase their calorie content, they make for a good variety of the product.

Which rice cakes technology do you need?

Vertical spindle mixer for dough processing

Optimize your dough consistency and quality with this vertical spindle mixer, ...

Precise dough sheet cutting station for bakeries

Efficiently shape and cut dough sheets for diverse snack and bakery produ...

Emithermic Xe zone for baking biscuits and crackers

Achieve precise baking and drying for your bakery products with a sys...

Convection oven with integrated dryer for large scale baking

Optimize your baking process with a convection oven that ef...

X-ray inspection system for large bulk products

Ensure consumer safety and product quality by efficiently detecting contam...

Metal detector conveyor system for food safety

Ensure product integrity across high-speed production lines with robust met...

Flexible packaging solution for large food volumes

For high-volume food packaging, achieving consistent bag sizes and red...

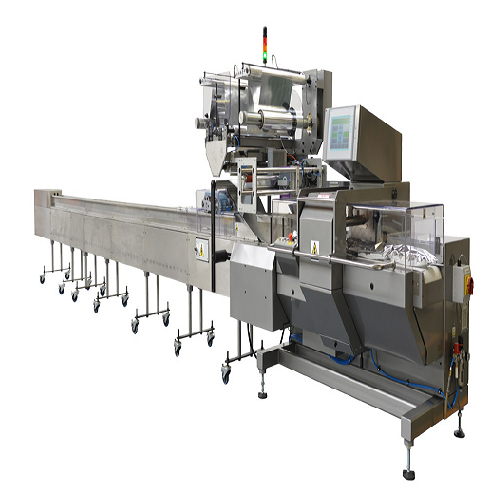

Flow wrapping solution for fresh produce and food products

Optimize packaging efficiency for irregular products with a v...

Conveyor systems for snack production

Streamline your snack production with advanced conveyor systems designed for seamless...

Oilseed flaking and milling system

Optimize your oilseed processing with a flaking system that enhances extraction efficien...

Twin-screw extruder for breakfast cereal

Optimize your production with a robust twin-screw extruder that accommodates high ...

High-speed case packer for snack bags

Optimize your packaging efficiency with a compact solution designed for seamless vert...

Production line for round and square cakes

Streamline your bakery operations with a modular cake production line designed ...

Multipack wrapping system for snacks

Streamline your snack packaging process with a machine engineered for high-speed, effi...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

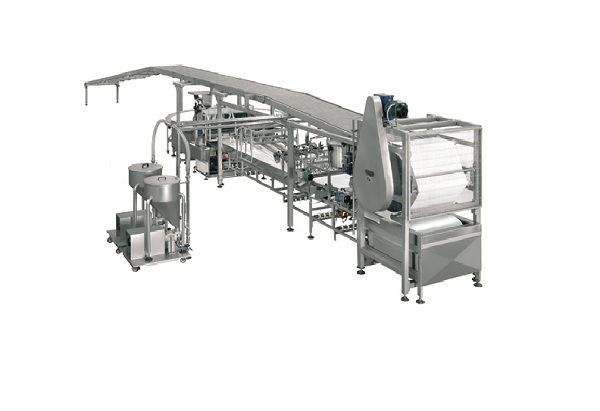

Rice cake making equipment for puffing natural and milled rice

For snack manufacturers seeking precision and versatility...

Airflow grain puffing machine

Unlock the potential of versatile snack production with precision-engineered airflow puffing t...

Texture analyser for food and cosmetics testing

Ensuring consistent product quality across diverse food and cosmetic appli...

Fully automated rice cake machine

When investing in a larger scale rice cake machine, marketability should be an important ...

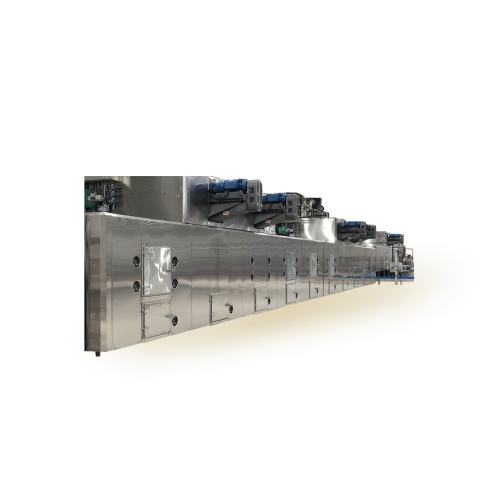

High capacity freezer for food

Freezing is one of the most important industrial methods for the long-term preservation of fo...

Robotic case packing machine for snack bags

Automated packing with robotic suction arms can quickly pickup packaged produc...

Line for sponge cakes production

Bringing together a wide range of process machinery to develop a production line for sponge...

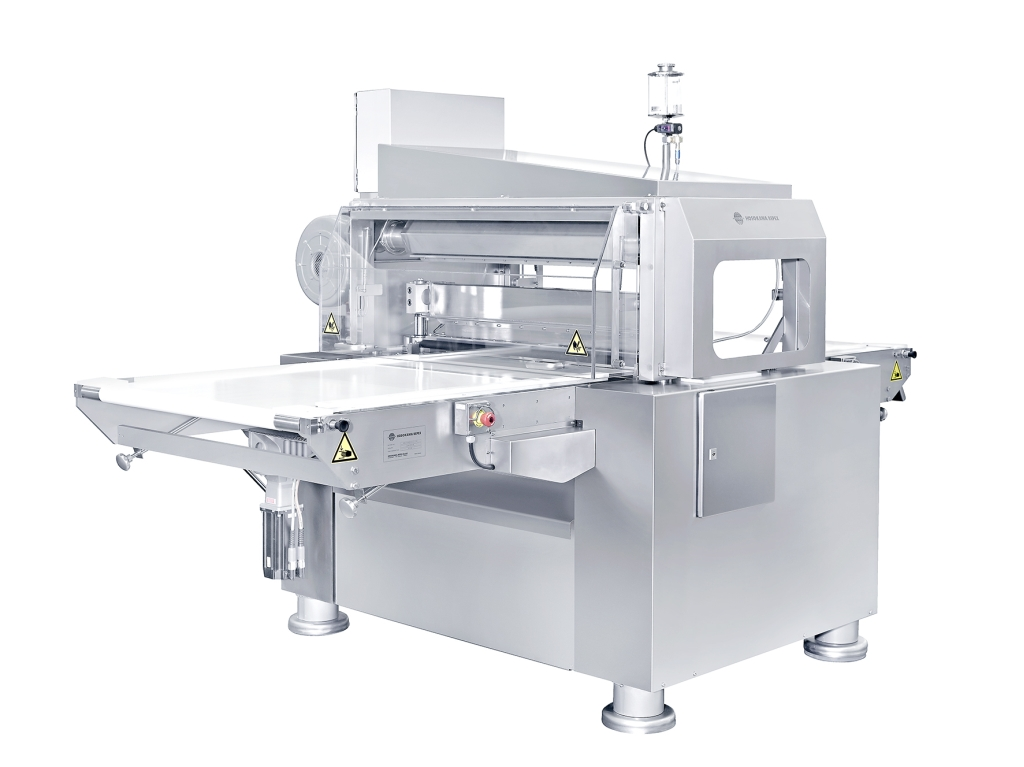

Cake ultrasonic cutter

Some cake items you may wish to cut can feature substantial amounts of cream. But that cream could sme...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Hygienic and fully-welded spiral freezer for food

Food freezers are often the last step in the food production chain. The...

High capacity spiral cooler for food

Cooling baked goods and food products can be problematic for sliced baked goods. A cru...

Strand forming machine for 2 masses

Form two-ingredient mixes into the shapes and layer combinations required for your fina...

High-speed strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other fina...

Chocolate coating machine

Coat your product with chocolate or caramel. This is a chocolate coating machine born of many year...

Slab forming machine

Turn the mixture of your ingredients, into continuous slabs for processing into bars, stands, or other s...