Making Nail Polish

Find innovative production technology for making nail polish and connect directly with world-leading specialists

Just when you think you've seen it all, you come to find out that there's nail polish on the market that costs $250,000. Yes, you got it right; two hundred fifty thousand dollars. And to think that the nail polish was originally a cocktail of beeswax, egg whites, gelatin, vegetable dyes, and gum arabic. Today, however, polymers, pigments and solvents are included in the mixture; when the mixture is ready, you can fill the bottles using nail polish filling equipment.

Tell us about your production challenge

Polymers, plasticizers, pigment and solvents… Just mix them and fill the bottle using nail polish filling equipment

Even though each manufacturer has its secret formula, there are still elements in common. Let’s start with nitrocellulose, a film-forming polymer, that forms the hard film on the surface of your nail, as the name implies. It is dissolved in a solvent such as ethyl acetate or butyl acetate which evaporates once the nail polish is applied so that nitrocellulose can dry forming the film.

By itself, nitrocellulose is brittle and doesn’t stick to the nail, so there is a chance that the polish will crack. To avoid this, manufacturers add plasticizers such as camphor to make the polish more flexible and tosylamide-formaldehyde resin to make the polish stick better to your nail.

But what makes your eyes sparkle when you see the nail polish is its many colors. Color is possible because of the pigments such as iron oxides. The color can fade when exposed to the sun, so benzophenone-1 is added to protect the nail polish from sunlight. After chemists find the right formula and the ingredients are mixed in a stainless steel kettle, the mixture is pumped into small bottles using nail polish filling equipment. The small bottles are sealed with a stopper having the bristle to paint your nail.

Regular nail polish vs gel nail polish – What lies behind it?

If you want to get comfortable and wait for your gel polish to air dry, you need to know that you can wait forever, because that’s never going to happen. Unlike regular nail polish, gel nail polish needs UV light to dry. But this is not enough. The ingredient that changes it all is a photoinitiator, which in most cases is benzoyl peroxide. The photoinitiator absorbs the UV lights starting the polymerization process, i.e. the solidification of the nail polish. In the gel nail polish, the benzoyl peroxide is mixed with a form of plastic called methacrylate that makes the gel more flexible.

Towards a more eco-friendly nail polish

It’s good to make things plain from the beginning; there is no such thing as zero waste nail polish. EPA (Environmental Protection Agency) and the European Union commission classify nail polish as household hazardous waste due to the toxic ingredients it’s made of, so it cannot be recycled. That’s because the bottles are impossible to clean thoroughly and there will always be some hazardous waste left behind. So throwing it in the trash is not an option, but it has to be disposed of as such.

To protect our health and our planet, the European Commission banned the use of what is called the Toxic Trio (toluene, formaldehyde and dibutyl phthalate) in nail polish in 2004. Compared to Europe, the United States has not restricted the use of these ingredients in cosmetic products. But despite this, manufacturers are trying their best to move towards more sustainable products. Apart from using more sustainable packaging or alternatives to plastic caps, they have eliminated this toxic trifecta from their formula, creating eco-friendly water-based nail polishes and using as few chemicals as possible or none at all. But this is true up to a point, because in order for it to adhere to the nail, you must always use plastic.

Processing steps involved in nail polish making

Which nail polish technology do you need?

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

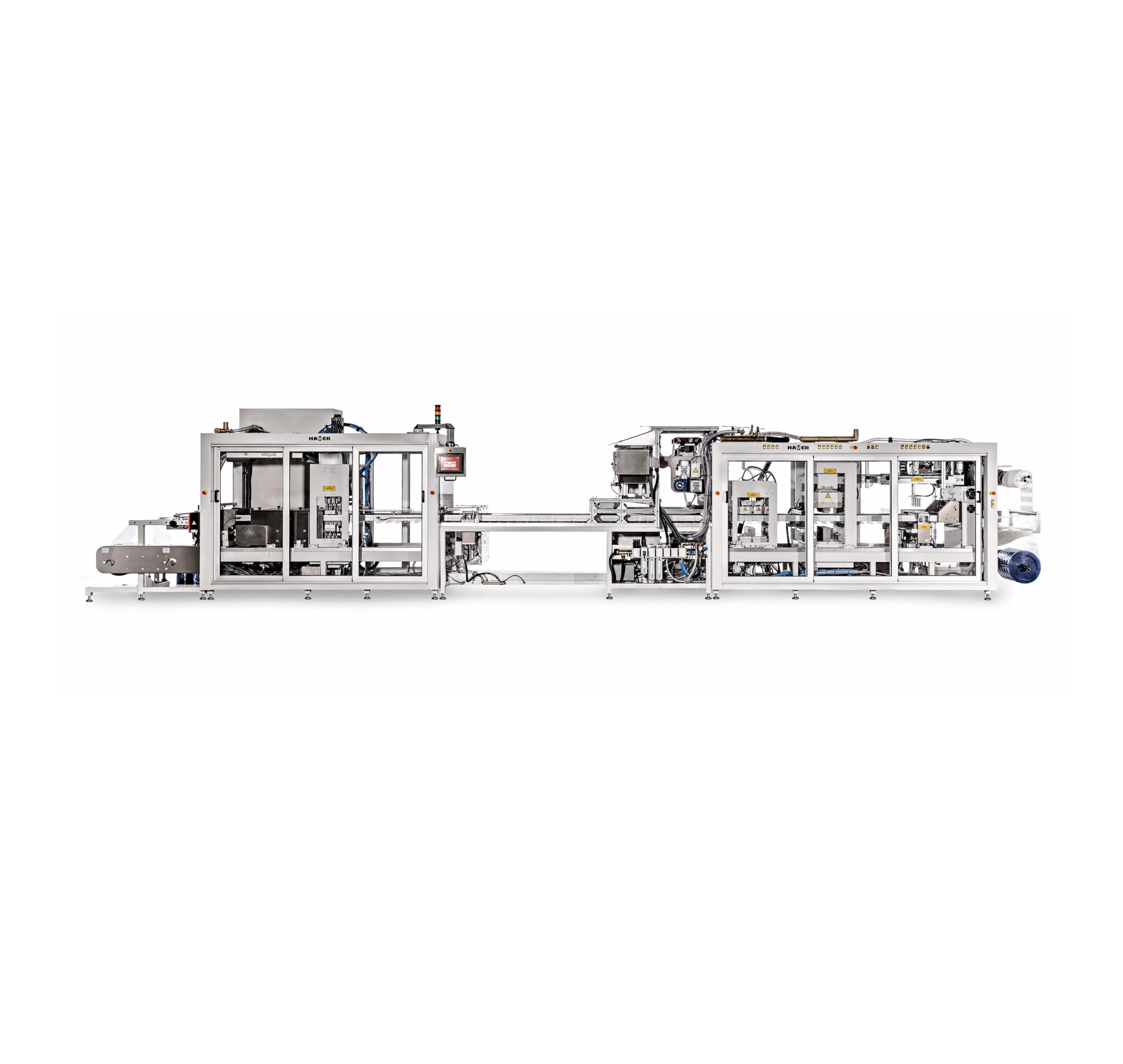

Automatic tube filling and closing for metal, plastic, and laminate tubes

Enhance your production efficiency with a hi...

Volumetric filling technology for cosmetic and food products

Achieve precise and contamination-free filling of liquid an...

Volumetric filler for packaging liquids and semi-solids

Optimize your filling process with precision control and adaptabl...

Semi-automatic volumetric piston filler

Achieve precise filling of diverse liquids and viscous products while minimizing wa...

Industrial jetstream mixer for homogeneous mixing

Achieve consistent product quality with precise micro and macro mixing ...

Pressure vessel for hazardous and non-hazardous liquids and gases

Ensure safety and compliance when handling hazardous ...

Continuous mill for nano range fine grinding

Achieve ultra-fine particle size in continuous processes, ensuring consistent...

Vacuum homogenizer for cosmetics and pharmaceuticals

Optimize your production with precision mixing and homogenizing, ess...

Volumetric piston fillers for liquid and dense products

Perfect for diverse packaging needs, these volumetric piston fill...

Volumetric piston fillers for dense liquid products

Ensure precise filling of liquids and dense products with versatile i...

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

Self-adhesive linear labeling machine for bottles

It is vital to have precise and long-lasting labels on bottles to avoid...

Semi-automatic blister sealing machines for retail

Blister packaging is mostly used in retail packaging for food, electro...

Automatic blister sealing machine for retail products

Blister packages for retail are usually designed with a paperboard ...

Industrial blister packaging machine for retail products

A blister can be simply defined as a type of packaging that cons...

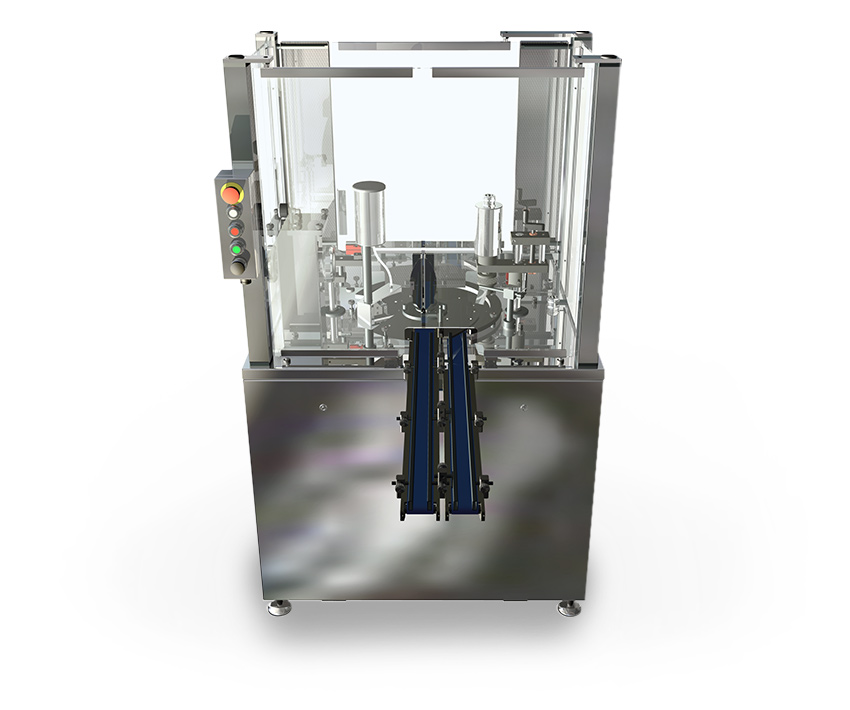

Automatic nail polish filling machine

Do you need to increase your production volumes in the most efficient way possible? A...

Semi-automatic filling machine for nail polish

Do you need to automate a smaller cosmetic line without the large costs ass...