Making Licorice

Find innovative production technology for making licorice and connect directly with world-leading specialists

Licorice is a glossy candy with firm consistency that can have different flavors, like chocolate, cherry and strawberry. With the right licorice making equipment, start by making a paste from the licorice roots, mixing them with sugar, flour and sweeteners. Extrude it with a nuzzle, allowing to cool, then cut and package it.

Select your licorice process

Tell us about your production challenge

Importance of quality assurance checks in licorice production

One of the methods of making licorice is cooking the sugar and licorice extract together and pouring it into molds full of cornstarch. There is also the licorice extrusion process, in which licorice root extract boils at 220-270 °C. After that, you add the colors and flavors. The mixture then cooks slowly until it is thick like a dough. Finally, you cut it into pieces.

Apart from these general steps, you need to carry quality checks on the licorice to guarantee that it fits the established standards. The quality assessment starts with testing the raw materials you will use for production. Lab technicians evaluate the ingredients and see whether they comply with the specifications. The tests must ensure that viscosity, pH levels and appearance of the licorice are adequate. Also, the color or texture of a sample licorice stick is compared to the standard licorice, to see if the quality matches.

Additionally, check the sensory characteristics, like the odor and flavor of the licorice. You can also examine other characteristics such as moisture content, size of solids and quantity of liquids.

What to consider when cooking and cutting licorice

Licorice is a sticky product, so, to cut it, use machines with stainless steel scraper blades and a heat exchange surface. These blades continuously remove any licorice that sticks to the machine. The non-sticky machine makes the process easier and more efficient. The licorice is pumped to the heat exchange surface for cooking; there, the blades continuously scrape the surface and mixes the licorice. The blades keep turning the licorice to ensure that there is even transfer of heat before moving it to the extruder and the cutting machine. A cutting machine helps you cut the roots into tiny pieces before extracting the paste.

Differences between sweet and salty licorice

Licorice can be salty or sweetened, and it’s in the mixing process that you define your product characteristic. Choosing ingredients carefully helps ensure some licorice’s characteristics, such as appearance and taste. The ingredients include sweeteners like sugar and corn syrup, as well as flour, that binds all the ingredients together. You need to add colorants, flavorings and preservatives, and can also use other natural flavors obtained from fruits, honey and berries.

Salty licorice contains both sugar and salt in its composition. The salty versions are more popular in Finland and Swedish while the sweet version is mostly consumed in the United States and Canada.

Processing steps involved in licorice making

Which licorice technology do you need?

Advanced metal detection for food processing

Maximize your production line’s safety and efficiency with a cutting-ed...

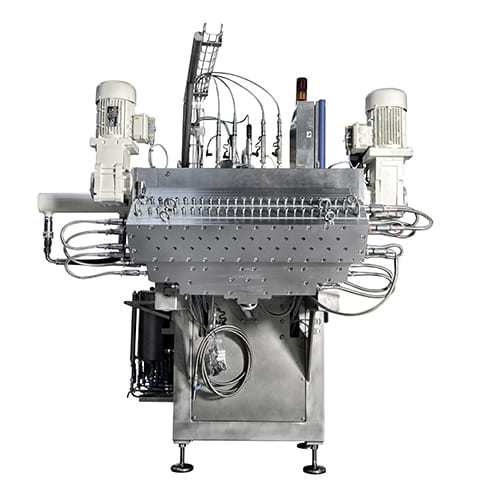

Automatic tray washer for gummy production cleanup

Eliminate gummy residue efficiently with high-pressure tray washing, e...

Cooking extruders for low shear confectionery production

For producers looking to create high-quality confectionery, this...

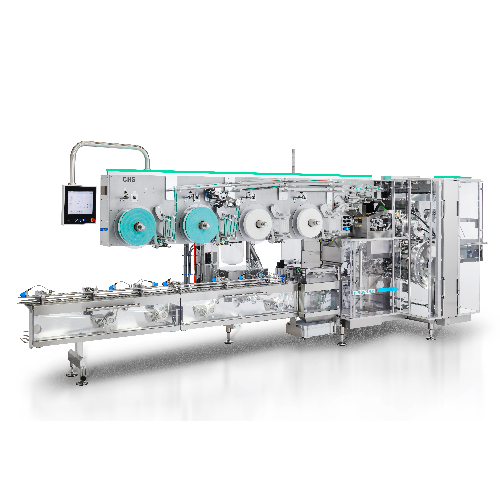

Multi-color and flavor confectionery production system

Maximize production flexibility with a single extruder that seamle...

Extrusion system for color changing confectionery strands

Easily switch colors in confectionery strands mid-production, ...

Confectionery forming extruders for viscous masses

Efficiently transform viscous ingredients into uniform, high-quality c...

Lab cooking and forming extruders for r&d

Optimize your R&D processes by testing new recipes and improving formulatio...

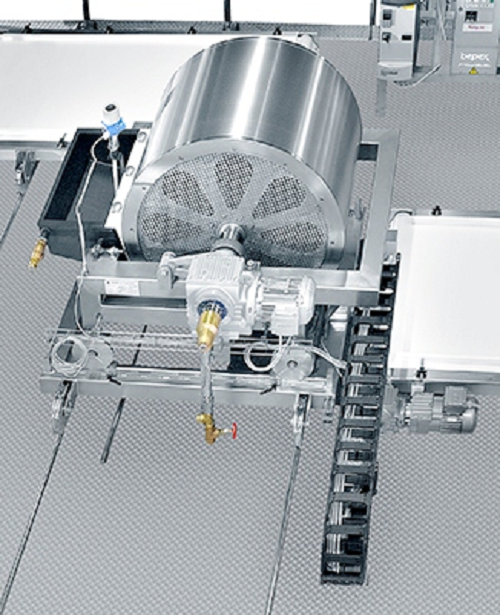

Slurry preparation for licorice production

Ensure a continuous and homogeneous feed of licorice slurry to your extruder, o...

Multilane wrapping solution for food and confectionery products

Enhance your packaging line efficiency with high-speed m...

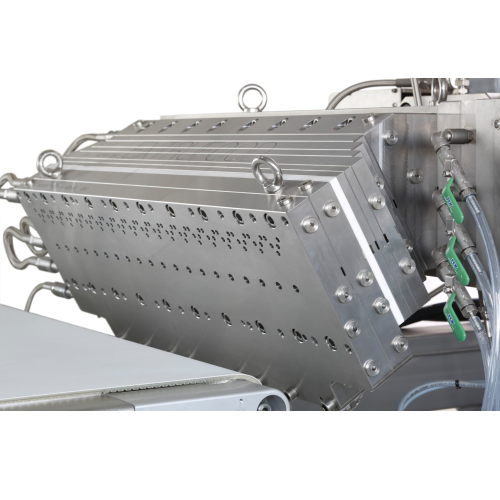

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Depositor and extruder for confectionery production

Enhance productivity with precision depositing and flexible extruding...

High-speed chocolate wrapping system

Optimize your confectionery packaging process with a versatile, high-speed wrapping so...

Case packer for diverse food products

Optimize your packaging line with this versatile case packer, capable of handling a w...

Scraped surface heat exchangers for high viscosity products

Ideal for continuous processing, these heat exchangers effic...

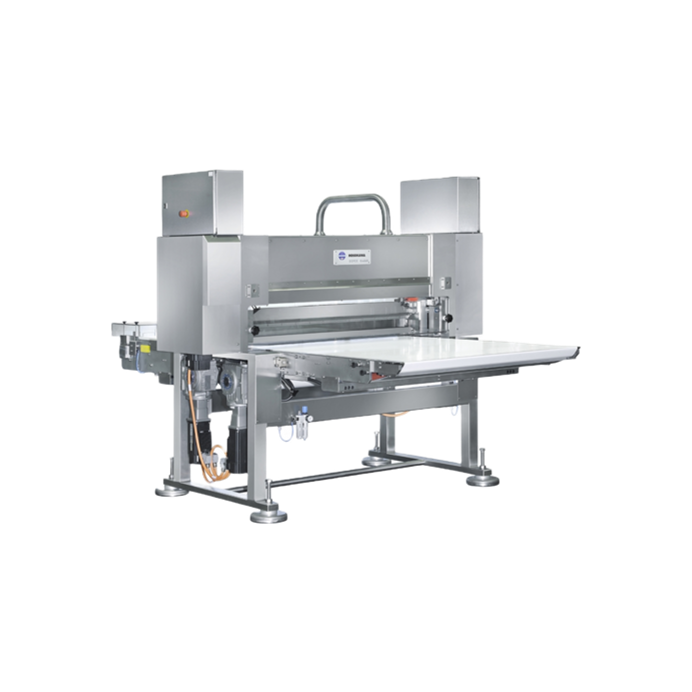

Guillotine cutter for confectionery

Confectionery products such as marshmallows, licorice candies, and fudges come out of e...

Industrial guillotine machine for extruded foods

Textured vegetable proteins made from soy, wheat, and oats are extruded i...

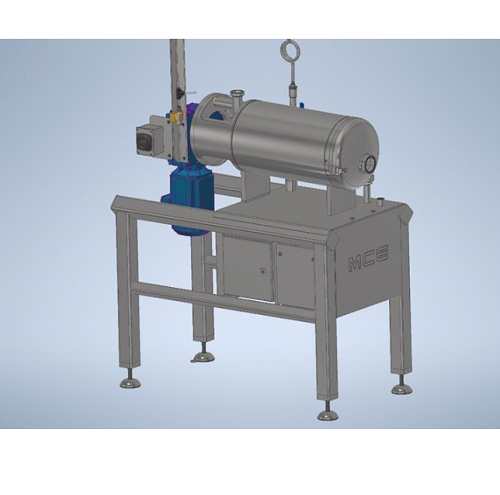

Licorice cooker

When producing liquorice and other sticky or viscous food products, during the cooling or heating process, com...

Cake ultrasonic cutter

Some cake items you may wish to cut can feature substantial amounts of cream. But that cream could sme...

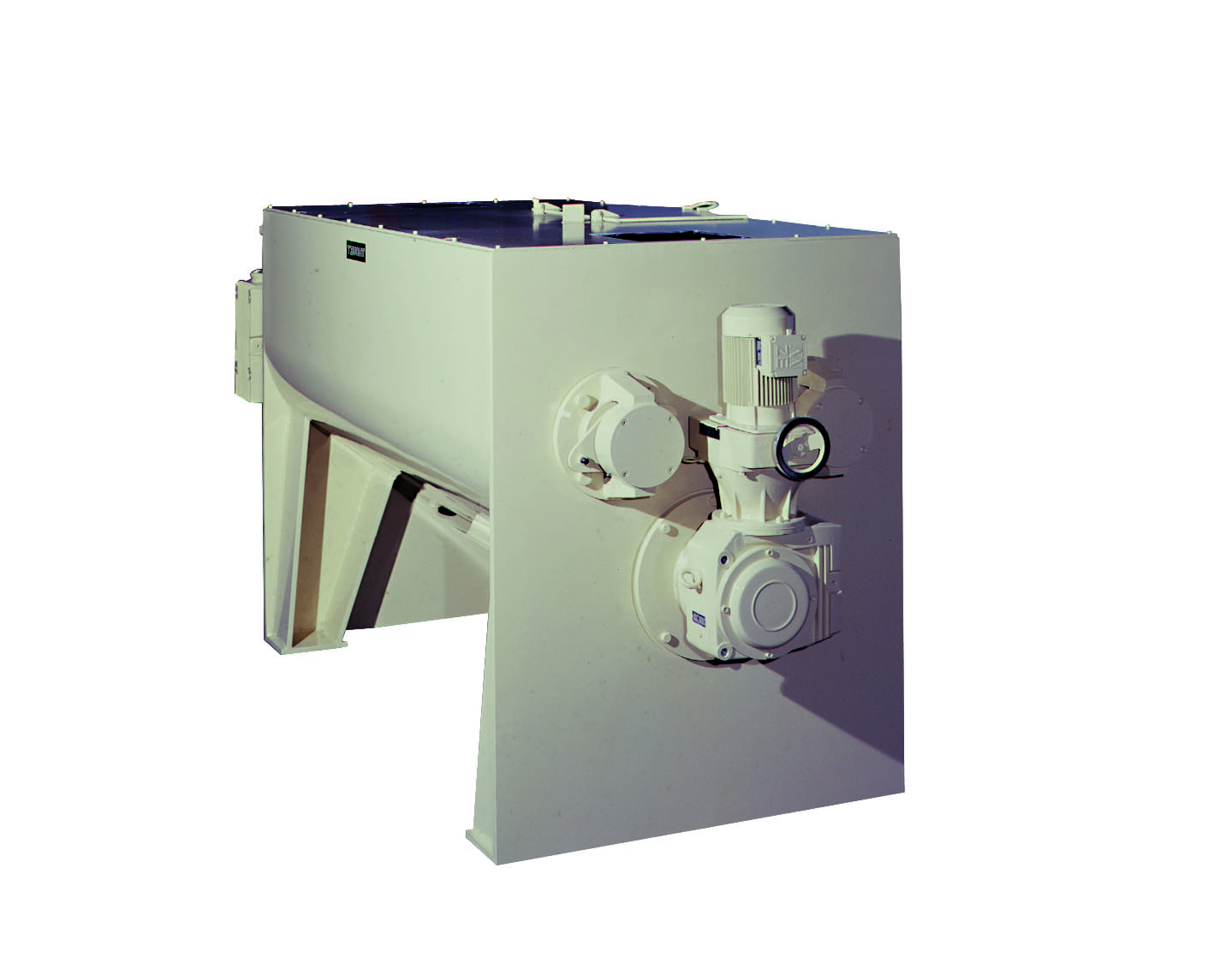

Horizontal dough mixer

The mixing of hard doughs or highly viscous product like chewing gum requires specialist equipment to ...

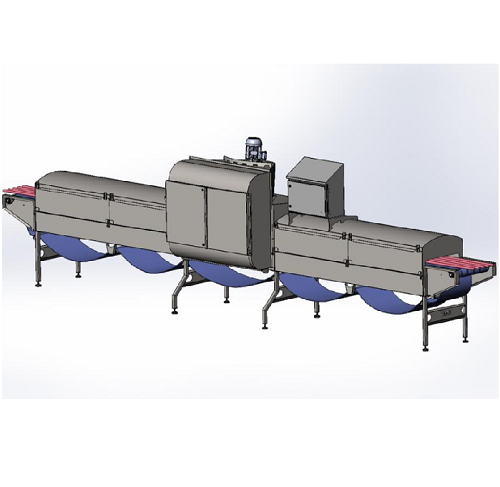

Licorice cooling tunnel

Licorice and other extruded food products like vegan meats can be tricky to cool in the production pr...

Mini sugar coating machine

The coating of grains or nuts with sugar is a popular process in the manufacture of many bakery p...

Inline ultrasonic food cutting machine

Cutting sticky products in the food sector is not always an easy process. Small scal...

Mixer and kneader for sugar based recipes

For the production of chocolate paste based on refined or icing sugar, the decis...

Hygienic vertical bagging machine

Hygienic bagging with a compact packing machine that can withstand the harshest wash down...

Automatic bread dough sheeter

Dough for speciality breads must first be rolled into sheets of varying thickness, to facilita...

Economical Pouch Packaging Machine

The side gusset pouch is a popular packaging solution for medium formats, particularly f...

Small sugar mill for entry level production

Sugar powder is a key ingredient in a wide range of bakery, confectionery, and...

Small scale dragee coating machine

Coated dragée products such as Jordan Almonds or hard-coated candies are very popular, b...

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...

Cooling drum for soft and caramel mixtures

Cool your product to the temperature required for further processing. This is a...

Whipping machine for soft candy

Prepare your ingredients for any whipped or aerated product component. This is a pressurized...