Hydrogen Production Equipment

Find innovative production technology for making hydrogen and connect directly with world-leading specialists

Industry sees a future powered by hydrogen fuel. The chemical element is an excellent energy carrier that could significantly reduce carbon dioxide emissions across sectors without upending economic models. The tricky part, however, is extracting it in its pure form.

Tell us about your production challenge

Hydrogen generation expected to grow

Demand for pure hydrogen stands at about 70 million tons annually and is expected to increase exponentially in the 2020s. At least a dozen countries from Chile to Japan and from Australia to Finland have already set out plans to ramp up output. The European Union and the United States have also rolled out polices to encourage the production of hydrogen.

Hydrogen is already heavily used in specialized sectors such as ammonia and fertilizer production, in flat-glass industries, and oil refinery. Meanwhile, manufacturers are exploring new applications in commercial areas ranging from semi-conductors to fuel-cell cars to light bulbs.

Making blue hydrogen

Over three-fourths of hydrogen production is generated from natural gas, particularly methane, using a method known as steam reforming. The gas is heated with steam to produce a mixture of chemicals from which hydrogen is then filtered out. Although efficient, this technique raises concerns about carbon dioxide emissions during the process. More producers are turning to Carbon Capture, Utilization & Storage (CCUS) systems to contain CO2 release, generating what is referred to as blue hydrogen.

Extracting green hydrogen by electrolysis

Another way of extracting hydrogen is by ‘water-splitting’ – separating oxygen from hydrogen using electricity as an energy source. An electrolyzer inserted in water converts the H2O into distinct hydrogen (H2) and oxygen (O) atoms, recovering the hydrogen gas. If the procedure is powered by low-carbon sources such as renewable energy or biofuels, hydrogen generated by alkaline water electrolysis is classified as green hydrogen.

Handling and shipping hydrogen energy is a barrier

The technology for producing green renewable hydrogen is already available and prices for renewable energy are becoming more competitive, but the handling of hydrogen comes with a raft of legal and technical limitations.

The chemical is highly explosive and its small particles make it more difficult to contain, making distribution of the gas less viable over long distances. Shipments may be liquefied, but the process of re-gasification brings new safety concerns.

Choosing to produce hydrogen on-site as a solution over your traditional supply chain

As the simplest and the most abundant element in the universe, hydrogen offers tremendous potential, but generating and controlling it requires specialized know-how.

Industrial suppliers are introducing new ways to make processes safer and more widely applicable. Manufacturers with more intense usage needs are exploring captive systems that generate hydrogen on-site. Companies producing fertilizer, cement, or glass are actively investing in on-site solution and storing surplus hydrogen for future use or to sell it back to the grid.

Fulfilling the promise of hydrogen

The versatility of hydrogen technologies make it an excellent driver of the green economy. Converting to hydrogen power is relatively uncomplicated and it does not result in any major disruptions for commerce whether manufacturing, agriculture, construction or transportation.

With ambitious international targets to cut greenhouse gas emissions across industries and regions, the coming decades are developing into the era of hydrogen.

Processing steps involved in hydrogen making

Which hydrogen technology do you need?

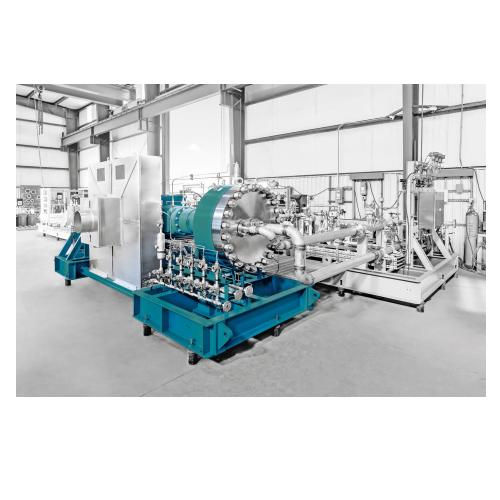

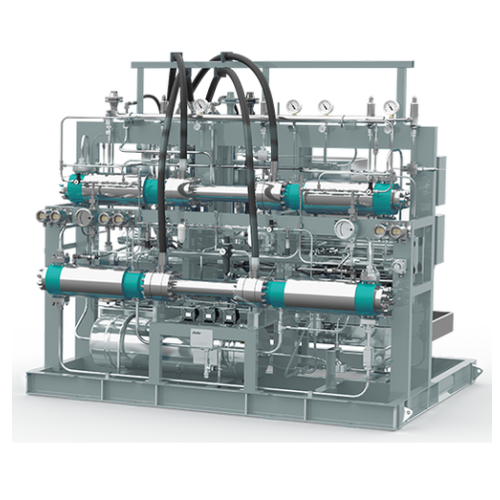

Compressor combinations for high-pressure applications

Optimize your energy infrastructure with specialized compressor co...

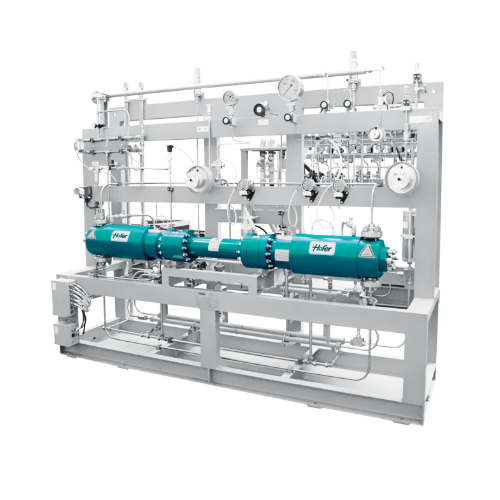

Industrial diaphragm compressor for high-purity applications

Experience reliable and contamination-free gas compression ...

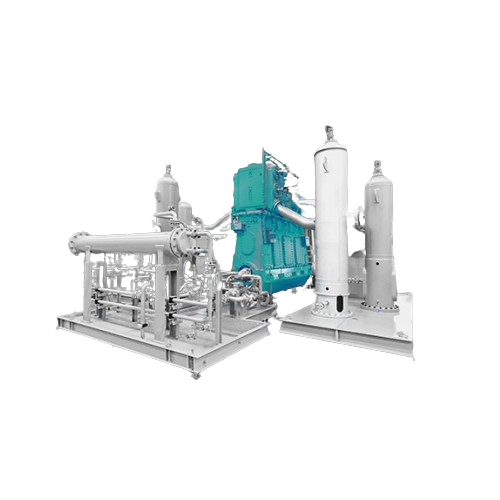

Hydraulically driven piston compressor for non-corrosive gases

Optimize your gas compression operations with a versatile...

Industrial piston compressors for various applications

Optimize your gas processing capabilities with versatile piston co...

Hydrogen refueling stations planning and construction

Facing challenges in setting up hydrogen infrastructure? Our soluti...

Pore size distribution analyzer

Optimize your material analysis with a system that delivers precise pore size distribution a...

Gas pycnometer for true density measurement of solids and powders

Achieve highly precise density measurements of solid ...

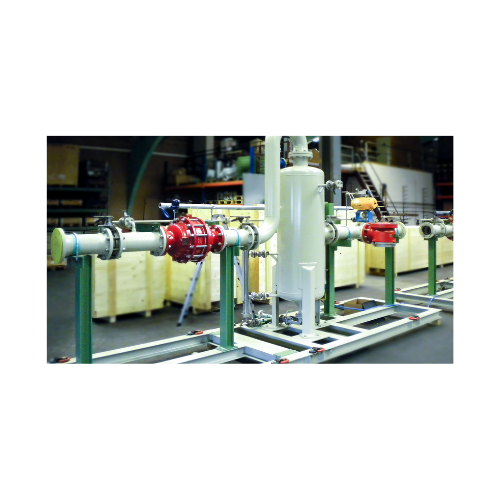

Gas contactor for hydrogen sulfide removal from biogas and sour gas

Efficiently convert harmful hydrogen sulfide into m...

Automotive assembly and leak testing systems

Optimize your production line with versatile assembly and testing systems, en...

Cylinder block leak testing system

Ensure reliability and quality by detecting and addressing leaks in cylinder blocks with...

Cylinder head leak testing systems

Ensure critical sealing integrity with advanced leak testing systems designed to accurat...

Electric drive unit testing systems

Optimize your electric vehicle production with comprehensive testing systems designed t...

Leak test system for engine components

Ensure the integrity of engine components with precise and efficient leak detection,...

Leak testing system for automatic transmissions

Ensure the integrity and functionality of your automatic transmissions wit...

Function test for electro-hydraulic control units (ehs)

Ensure precise functionality and reliability in your production l...

Industrial carbon capture system for flue gas

Capture and transform combustion flue gas into valuable CO2 outputs with our...

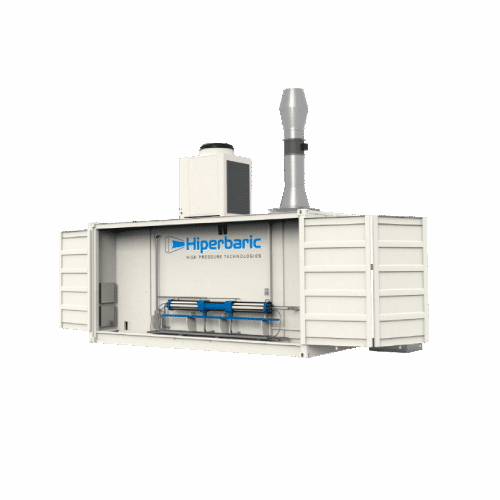

Hydrogen compression solution for refueling stations

For operations demanding efficient hydrogen compression, this modula...

Industrial wire screens for efficient material separation

Streamline your packaging and production process with custom-e...

Consumables for elemental analyzers

Optimize your laboratory’s elemental analysis with high-quality consumables desig...

Water purification system for Pem electrolyser

Achieve premium water purity essential for hydrogen electrolysers with this...

Hydrogen gas safety system for high-temperature tube furnaces

Ensure safe and efficient hydrogen gas handling in high-te...

Synthesis gas cooler for partial oxidation of oil or natural gas

Optimize high-temperature gas streams efficiently by em...

Reformed gas waste heat boiler with variable tube sheet

Achieve precise heat recovery and temperature control in high-pre...

Industrial steam superheaters

Optimize energy efficiency and achieve precise steam temperature control with advanced steam s...

Synthesis gas waste heat boiler for ammonia plants

Enhance your ammonia production with cutting-edge waste heat recovery ...

Integrally geared centrifugal compressors for process gases

Optimize your production efficiency with our integrally gear...

Reciprocating compressors for process gases Api 618

For efficient compression of process gases, this advanced reciprocati...

Ethylene cracking gas cooling system

Quickly reduce gas temperatures in high-capacity ethylene plants with a robust cooling...

Voc emission reduction unit for ship loading

Ensure safe and efficient marine vapour recovery with a compact, integrated s...

Vapour recovery unit for terminals and refineries

Efficiently capture and recover valuable hydrocarbons from gas streams,...

Hydrogen separation membranes for refineries

Optimize hydrogen recovery and purification in your production line with adva...

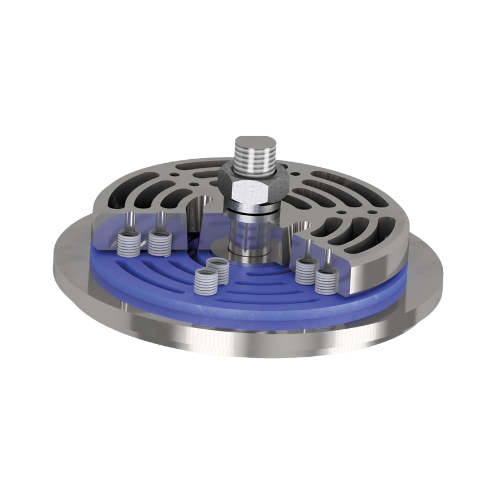

Plate valves for compressors handling all gases

Ensure reliable gas compression with innovative plate valves designed for ...

Valve reconditioning, analysis, and optimization

When your compressor valves fail to reach optimal performance, this solut...

Ring valves for industrial compressor systems

Optimize the efficiency and reliability of your gas compression processes wi...

Hydrogen peroxide ultrafine particle sterilizer for contamination control

Ensure thorough sterilization in small space...

Industrial ejectors for reliable jet pump applications

Enhance process efficiency and reliability with industrial ejector...

Natural gas compression system

Optimize gas compression and boost efficiency with advanced screw technology, designed for se...

Industrial dissolver for high viscosity products

Optimize high-viscosity product dispersion with a robust dissolver design...

Laboratory stirrers for high viscosity materials

Efficiently mix and stir high-viscosity materials with ease, enabling pre...

Explosion-proof dissolvers for laboratory use

Ideal for safely dispersing and mixing chemical substances in potentially ex...

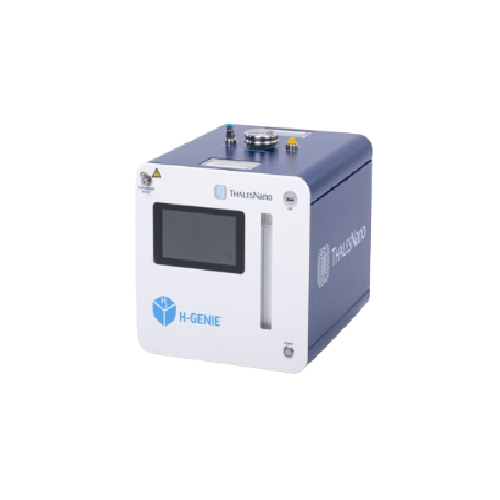

On-demand hydrogen generation system for laboratory use

Eliminate the risks and inconveniences of traditional hydrogen cy...

High-pressure hydrogen generator for laboratory use

Replace cumbersome hydrogen cylinders with an on-demand generation so...

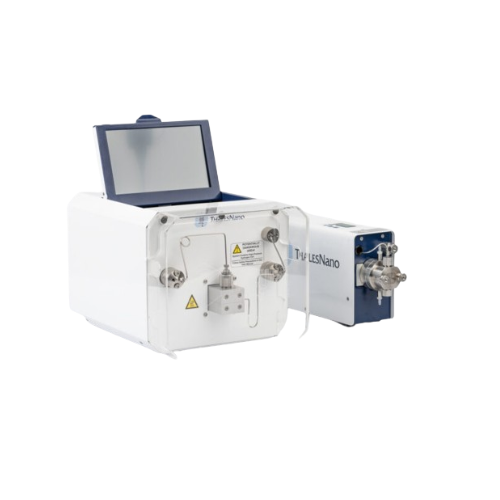

Hydrogenation reactors for safe and efficient syntheses

Experience safe, on-demand hydrogen generation for precise flow h...

Advanced hydrogenation in continuous flow

Achieve precise, on-demand hydrogenation with advanced safety features, eliminat...

Hydrogen peroxide biodecontamination unit

Achieve precision in sterile environments with a reliable vaporized hydrogen per...

Plug and play natural gas to hydrogen generator

Hydrogen is an all-purpose element and can be simply defined as energy’s S...

Gas recovery for the glass industry

A reliable and constant supply of industrial gases is essential in producing quality fl...

Plug & play water to hydrogen generator

One of the highest volume industrial gases, hydrogen serves a wide range of applica...

Containerized hydrogen upgrading system

Usually, all spent protective gas is vented from metal treatment processes, such as...

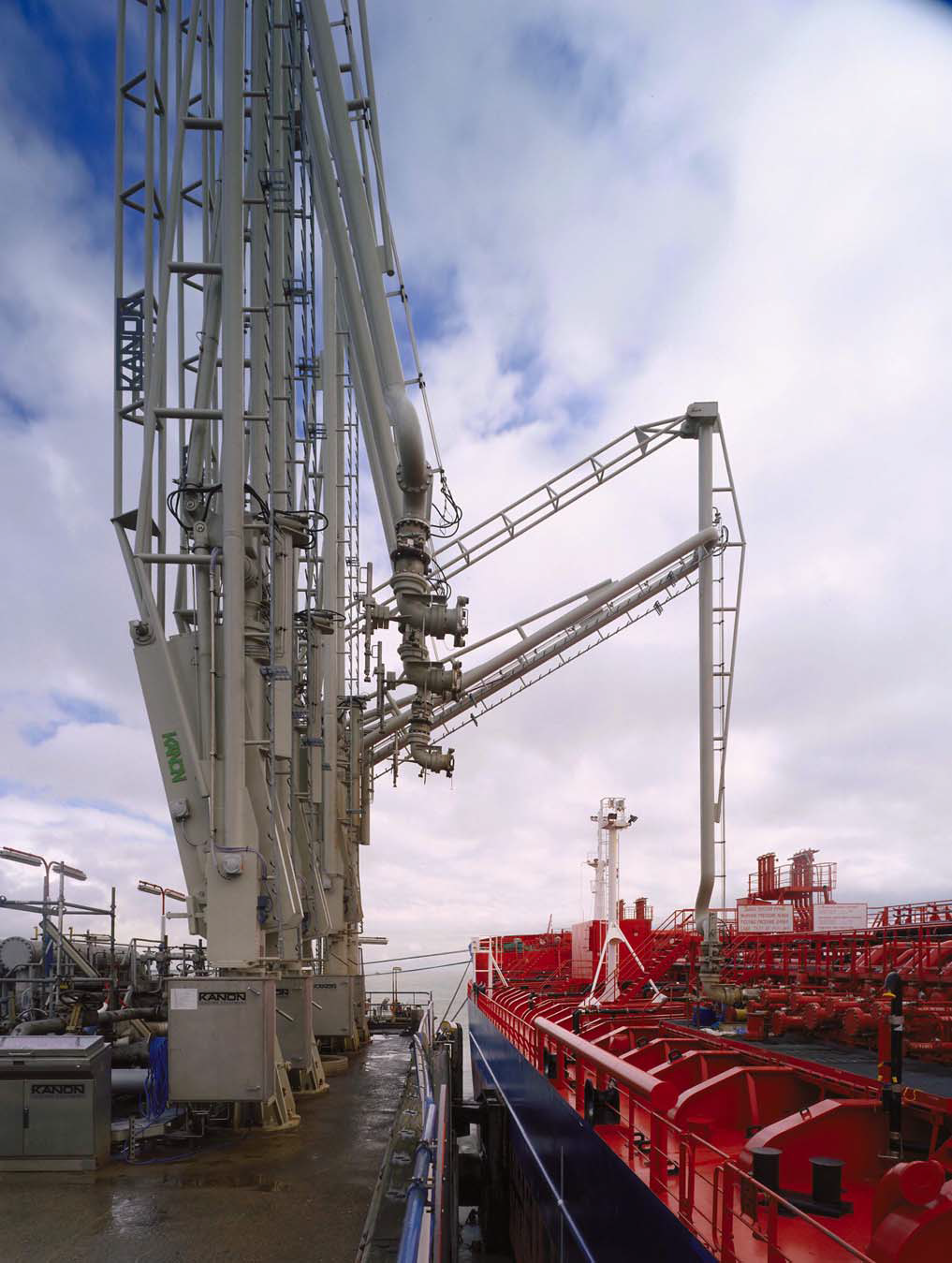

Marine loading arm

A hose or loading arm is needed when you load or unload fluids from a ship or transfer fluids between vess...