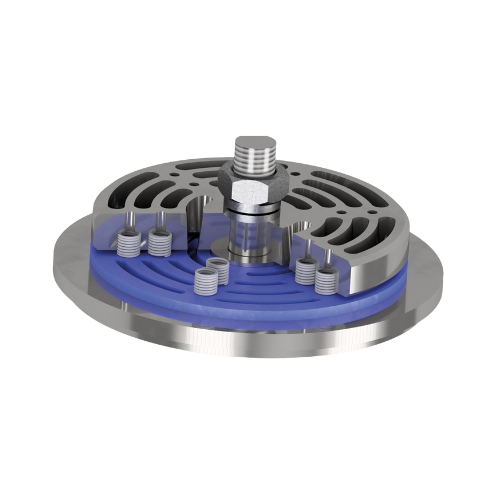

Plate valves for compressors handling all gases

Ensure reliable gas compression with innovative plate valves designed for seamless integration, reducing the impact of liquid hammers while maximizing operational durability and efficiency.

Compresses and Regulates Industrial Gas Flows

The BORSIG ZM plate valves offer a robust solution for gas compression across diverse industrial applications. Utilizing durable non-metallic valve plates made from materials like PEEK and PA, these valves significantly reduce consequential damage from liquid hammers and ensure longevity under harsh conditions. Designed for simplicity in installation, they enable rapid overhauls which can be crucial in operations lacking immediate service support. Perfect for environments handling heavily polluted gases, the plate valves maintain reliability with variable slot-width valve seats, delivering sustainable sealing performance. These valves are commonly employed in industries like oil and gas, petrochemicals, and environmental technology, processing end-products such as purified ethylene, hydrogen fuel, and recovered hydrocarbons. Their design includes provisions for manual and continuous operations and offers customization options in materials to ensure optimal chemical compatibility.

Benefits

- Enhances operational reliability under extreme conditions, minimizing disruptions.

- Extends service life through non-metallic valve plates, reducing maintenance costs.

- Facilitates quick overhauls with straightforward installation, minimizing downtime.

- Ensures sealing integrity in contaminated environments, maintaining performance efficiency.

- Offers material flexibility, catering to diverse chemical applications.

- Applications

- Energy applications, Hydrogen production, Industrial applications, Nitrogen recovery, Compressors, Liquid separation, Ethylene production, Petrochemicals, Emission control, Product recovery, Hydrocarbon processing, Gas separation, Gases, Marine applications, Environmental applications

- End products

- Polyethylene, Ethylene oxide, Refined natural gas, Chemical feedstocks, Marine vapor emissions, Purified ethylene, Commercial nitrogen, Propylene glycol, Refrigerants, Ethylene glycol, Recovered solvents, Hydrogen fuel, Industrial oxygen, High-purity hydrogen gas, Petrochemical intermediates, Recovered hydrocarbons, Industrial nitrogen

- Steps before

- Purification, Drying

- Steps after

- Packing, Coating

- Input ingredients

- all gases, heavily polluted gases, condensates

- Output ingredients

- compressed gas

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Material Type

- PEEK, PA, GFK, Steel

- Durability

- High (Non-metallic plates)

- Installation Type

- Uncomplicated installation

- Valve Design

- Variable slot widths

- Sealing Type

- Sustainable sealing effect

- Operation Environment

- Extreme conditions with heavily polluted gases

- Reliability

- Proven over decades

- Maintenance

- Prompt overhaul capability

- Working Mechanism

- Reciprocating and integrally geared

- Batch vs. continuous operation

- Continuous

- Material Adaptability

- Non-metallic and metallic

- Durability under Stress

- High durability against liquid hammers

- Reliability in Polluted Environments

- Proven under heavily polluted gases

- Sealing Effect

- Sustainable sealing with narrow face

- Material Used

- PEEK, PA, GFK, Steel

- Durability under Liquid Hammers

- High

- Corrosive Resistance

- Non-metallic plates for corrosive protection

- Valve Plate Material

- PEEK, PA, GFK, Steel

- Durability

- High resistance to liquid hammers

- Installation

- Uncomplicated and effective

- Valve seat design

- Variable slot widths