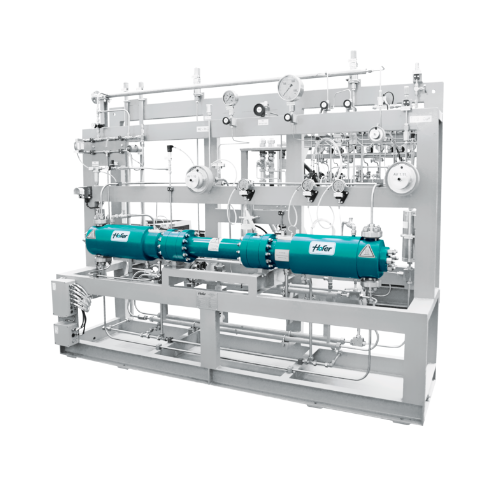

Hydraulically driven piston compressor for non-corrosive gases

Optimize your gas compression operations with a versatile, hydraulically driven system designed for high-pressure, lubricant-free performance, ensuring minimal maintenance and integration ease into compact spaces.

Compresses and Cools High-Pressure Industrial Gases

The NEA|HOFER TKH, a product of NEUMAN & ESSER, is a hydraulically driven, dry-running piston compressor engineered for high-pressure applications. Featuring a lubricant-free design, it efficiently compresses gases like hydrogen, helium, and argon without the risk of contamination, making it ideal for industrial gas processing and the hydrogen economy.

Operating with a discharge pressure of up to 4,200 bar, its modular, multi-stage construction allows for easy installation in confined spaces, such as containers. The compressor’s ability to operate without lubricants is achieved through specially developed materials for piston packing, ensuring gas purity.

Engineered for versatility, it supports continuous, automatic operation with up to 100% variable speed control, enhancing its integration into diverse processing lines. With robust wear resistance, it guarantees smooth operation and minimal maintenance time, as piston seals can typically be replaced within 10 to 30 minutes.

This compressor also features efficient water-cooling for optimal thermal management and noise reduction, complying with European safety and explosion-proof directives. Options for corrosion-resistant materials are available, accommodating aggressive environments and industrial gases.

For enhanced operational transparency, the compressor is capable of constant leakage rate monitoring and includes optional sensors for gas and oil leak detection, ensuring high reliability and safety standards across its applications.

Benefits

- Ensures gas purity through lubricant-free compression, critical for sensitive applications like hydrogen fuel cells and helium for MRI machines.

- Reduces maintenance downtime with quick piston seal replacement within 10 to 30 minutes.

- Enables seamless integration into compact spaces with its modular, space-saving design.

- Enhances operational safety with continuous leakage monitoring and optional explosion-proof configurations.

- Lowers noise levels and improves cooling efficiency through advanced water-cooling technology.

- Applications

- Argon, Helium, Carbon dioxide, Green gas industry, Oil and gas, Ethylene, Hydrogen economy, Nitrogen, Hydrogen, Industrial gas processing

- End products

- Carbonated beverages, Liquefied natural gas (lng), Renewable gas, Argon for welding, Helium for mri machines, Nitrogen for food packaging, Biogas upgrading, Ethylene for polyethylene production, Hydrogen fuel cells, Hydrogen-powered vehicles

- Steps before

- Gas Purification, Gas Drying

- Steps after

- Gas Cooling, Gas Storage

- Input ingredients

- hydrogen, helium, argon, nitrogen, carbon dioxide, ethylene

- Output ingredients

- compressed hydrogen, compressed helium, compressed argon, compressed nitrogen, compressed carbon dioxide, compressed ethylene

- Market info

- Neuman & Esser Group is known for its expertise in manufacturing compressors and grinding systems. They hold a strong reputation for providing durable, high-quality engineered-to-order equipment, particularly in the oil and gas, chemical, and energy industries.

- Discharge pressure

- up to 4, 200 bar

- Piston type

- Dry-running

- Compression stages

- Variable number of stages

- Stage pressure ratio

- up to 5

- Piston speed

- Low speeds for wear resistance

- Installation requirement

- Foundation-free due to mass compensation

- Cooling method

- Water cooling

- Monitoring capability

- Constant monitoring of leakage rates

- Noise level

- Low sound pressure level

- Compliance

- 2006/42/EC EC-Machinery Directive

- Explosion proof capability

- According to 2014/34/EU Directive

- Operation mode

- Hydraulically driven

- Seal replacement time

- 10 to 30 minutes

- Flow control

- Easy control by changing strokes (5 to 100)

- Cooling circuit

- Hydraulic unit also connected to cooling circuit

- Working Mechanism

- Hydraulically driven, dry-running piston

- Gas compatibility

- Non-corrosive gases like hydrogen, helium, argon

- Maintenance ease

- Piston seal replacement in 10 to 30 minutes

- Space efficiency

- Small space requirement, stages can be arranged vertically

- Flow regulation

- By changing the number of strokes from 5 to 100

- Sound and cooling features

- Water cooling for low sound pressure level

- Leakage Monitoring

- Constant monitoring of leakage rates

- Suction capacity regulation

- Continuous regulation via standard analogue signal

- Explosion-proof capability

- Explosion-proof hydraulic units available on request

- Stage Pressure Ratio

- Up to 5

- Operation Principle

- Two-stage or one-stage double-acting design

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- EC-Machinery Directive

- 2006/42/EC

- Explosion Proof Certification

- European Directive 2014/34/EU

- Applied Standards

- DIN EN 1012 part 1

- Applied Standards

- DIN EN 12100 part 1

- Applied Standards

- DIN EN 60204 part 1

- Machine footprint

- Small space requirement

- Installation type

- Foundation-free installation

- Stage arrangement

- Stages can be arranged above one another

- Container compatibility

- Ideal for installation in containers

- Piston seal replacement

- 10 to 30 minutes

- Hydraulic unit location

- Outside ex-zone

- Explosion-proof option

- Available upon request

- Installation configuration

- Stacked for container installation

- Number of stages

- Variable, 1 or more

- Piston speed control

- Variable, 5 to 100 strokes

- Continuous capacity regulation

- 0% to 100% via analogue signal

- Leak detection instruments

- Available upon request