Valve reconditioning, analysis, and optimization

When your compressor valves fail to reach optimal performance, this solution offers precision reconditioning and modification to restore efficiency and prevent frequent replacements.

Optimizes Gas Compression and Recovery Processes

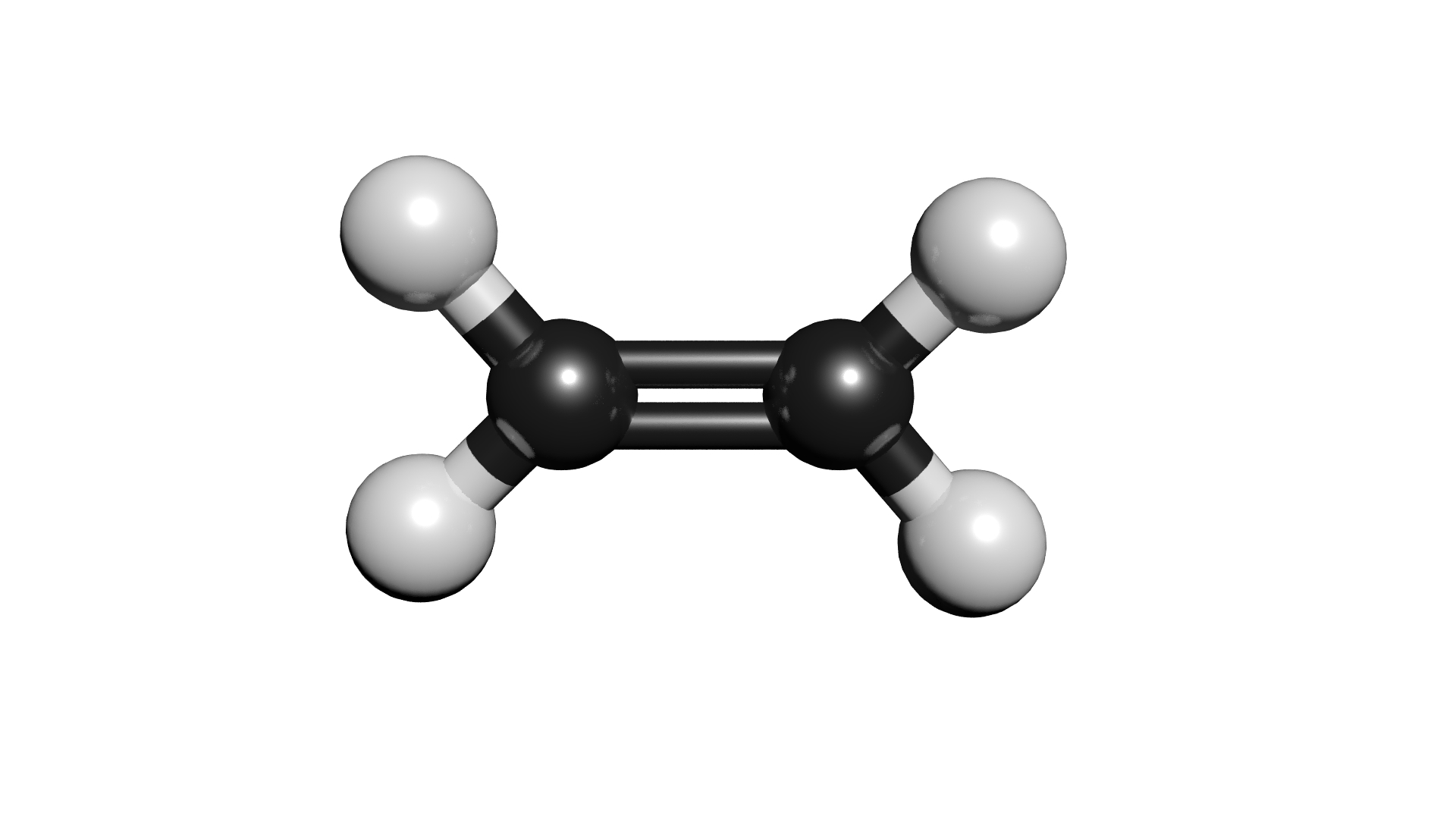

BORSIG ZM Compressor Valves are engineered for optimal performance in demanding industrial applications. Designed to enhance the efficiency of gas compression systems, these valves are integral in maintaining pressure control and minimizing leaks across various sectors, including chemical, petrochemical, and power generation. The robust design of these valves allows for reconditioning and modification to meet specific operational needs, ensuring long-lasting utility and reduced lifecycle costs. These compressor valves are compatible with a range of gases, including hydrogen, ethylene, and nitrogen, and are suitable for continuous and high-speed operations. The valves feature high-performance plastics and metal components that provide excellent resistance to harsh chemicals and temperature variations, making them suitable for challenging environments. Additionally, BORSIG ZM offers full reconditioning services to restore valve efficiency, extending service life without the high costs of complete replacements. With seamless integration into existing systems and compliance with industrial standards, these valves deliver reliable and efficient operation, complemented by expert engineering support for customized solutions.

Benefits

- Extends service life with cost-effective reconditioning, minimizing replacement needs.

- Enhances system reliability by optimizing pressure management and reducing leak potential.

- Customizable to specific operational requirements, ensuring compatibility and performance.

- Durable materials provide resistance to chemical and temperature variations, ensuring longevity in harsh environments.

- Continuous operation capability improves overall production efficiency.

- Applications

- Compressor valves, Liquid separation, Gas compressors, Heat recovery systems, Emission control, Product recovery, Industrial service, Power plant service, Gas separation

- End products

- Propylene, Synthesis gas, Reformed gas, Hydrocarbons, High-purity gases, Purified exhaust gases, Monomers, Process gas, Ethylene, Recovered vapors, Nitrogen, Boiler feed steam, Hydrogen, Aromatics

- Steps before

- Analysis, Optimization, Modification, Reconditioning

- Steps after

- Maintenance, Efficiency Restoration

- Input ingredients

- process gases, compressed gases, synthesis gas, reformed gas, nitric acid, hydrogen, propylene, ethylene

- Output ingredients

- emission control, energy recovery, carbon capture, vapor recovery, hydrocarbon recovery, nitrogen recovery, ethylene recovery, process optimization

- Market info

- BORSIG is known for its expertise in manufacturing high-quality industrial engineered-to-order (ETO) equipment, including pressure vessels, heat exchangers, and compressors, with a strong reputation for engineering excellence and reliability in the petrochemical and chemical industries.

- Process type

- Reconditioning

- Valve type

- Plate / Ring

- Compressor type

- Reciprocating / Integrally Geared Centrifugal

- Automation

- Manual / PLC-controlled

- Modification options

- Valve materials, Springs

- Valve Reconditioning Frequency

- Per specified maintenance intervals

- Modification Capacity

- Includes replacement of springs and valve plates

- Efficiency Retention

- Reconditioned valve retains same lifetime as new

- Adaptability to Operating Conditions

- Adjustable for variable conditions

- Automation Level

- Manual modifications available

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Feed/discharge method

- Pneumatic / Mechanical

- Configuration

- Vertical / Horizontal

- Materials used

- Stainless steel / Alloy

- Control panel type

- Digital / Analog

- Mounting type

- Skid-mounted / Floor-standing

- Design flexibility

- Customizable / Modular

- Access points

- Multiple / Central

- Enclosure type

- Open / Closed

- Valve types

- Plate / Ring / Ball

- Control panel type

- Digital / Touchscreen

- Integration possibilities

- PLC / SCADA

- Material choice

- Stainless steel / Alloy

- Valve type

- Plate / Ring

- Membrane type

- Organic / Inorganic

- Modification options

- Closing / Damper spring

- Compressor type

- Reciprocating / Centrifugal