Cylinder head leak testing systems

Ensure critical sealing integrity with advanced leak testing systems designed to accurately identify and address defects in engine components, enhancing reliability and performance in demanding operational environments.

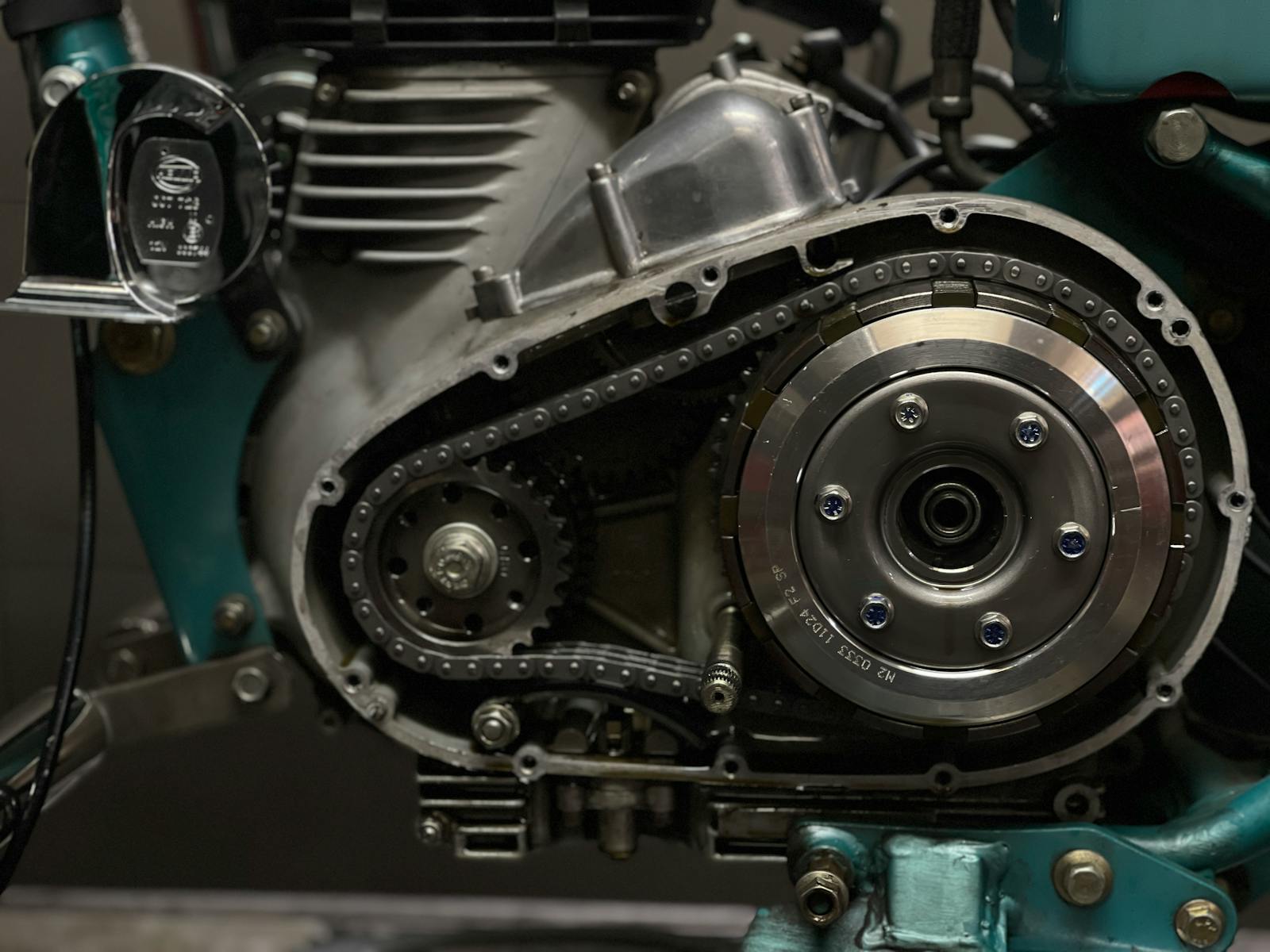

Tests and Assembles Cylinder Head Components

The comprehensive solutions from JW Froehlich Maschinenfabrik, including their cylinder head leak testing and assembly machines, offer precise control and efficiency for manufacturers in the automotive and medical technology sectors. These machines combine leak testing and assembly functions, enabling accurate sealing and component integration in cylinder heads and other critical components like valve seat inserts and turbocharger housings. Utilizing flexible robotic systems and gantry machines, they support automated handling and assembly, saving time and minimizing manual intervention. Designed for high-speed and continuous operations, they ensure the detection and correction of leaks before reintegration into the production line. JW Froehlich’s systems also support seamless integration into existing processing and pre-processing lines, tailored to customer needs with custom-engineered sealing elements and assembly options. The equipment is constructed for durability and user-friendly maintenance, promoting operational efficiency and reliability.

Benefits

- Enhances production accuracy by integrating leak detection with component assembly.

- Minimizes manual intervention with automated, robotic handling systems.

- Reduces cycle times, boosting overall production throughput.

- Customizable to specific customer requirements for seamless integration.

- Low maintenance design ensures long-term operational reliability.

- Applications

- Transmissions, Engines, Cylinder blocks, Medical technology components, Automotive components, Fuel cells, Cylinder heads, Turbochargers, Electric drives, Batteries

- End products

- Turbocharger housings, Medical device housings, Engine block castings, Valve guides, Electric drive unit components, Cylinder head gaskets, Hydrogen fuel cells, Automatic transmission assemblies, Valve seat inserts, Battery pack assemblies

- Steps before

- Pre-machining of cylinder head, Preparation of valve seat rings, Preparation of valve guides, Preparation of bearing covers

- Steps after

- Reintegration into assembly line, Final assembly, Quality assurance, Documentation of process data

- Input ingredients

- cylinder head, sealing parts, valve seat rings, valve guides, bearing covers, water cavities, oil cavities, fuel cavities

- Output ingredients

- assembled cylinder head, tested cylinder head, leak-free components

- Market info

- JW Froehlich is known for manufacturing and supplying state-of-the-art testing and assembly systems for automotive and other industrial applications, renowned for precision, innovation, and expertise in tailor-made engineered solutions.

- Automation

- Highly flexible robotic systems

- Leak Detection

- Automatic checking in water, oil, and fuel cavities

- Integration

- Complete processing or assembly line

- Accuracy

- Quick and precise data collection and comparison

- Assembly Depth Precision

- Press-in depth of valve guides

- Planar Setting Precision

- Exact planar setting of the rings

- Cycle Time

- Stipulated cycle time assurance

- User-friendliness

- Designed to be user-friendly and low-maintenance

- Construction

- Solid and reliable

- Cooling Method

- Gantry machines with robot handling

- Automation level

- PLC / Robotic Systems

- Integration into Assembly Line

- Seamless / Flexible

- Batch vs. continuous operation

- Inline Continuous

- Testing Flexibility

- Highly Flexible

- Precision Testing

- High precision

- Leak Localization

- Automatic

- Error Detection and Repair

- Automated error localisation and repair

- Assembly Speed

- Industry Standard Cycle Time

- Technology Integration

- Robotics / Automation

- User-friendliness

- High

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Assembly Process

- Valve seat rings, valve guides, bearing covers

- Machine Footprint

- Flexible

- Discharge Method

- Automated/Manual

- Control Panel Type

- PLC Controlled

- Assembly Type

- Overhead Transfer / Flexible Assembly Centers

- Control panel type

- Touchscreen / Manual switches

- Integration possibilities

- SCADA / ERP systems

- Automation level

- Manual / PLC / SCADA

- Custom sealing elements

- Tailored to customer requirements