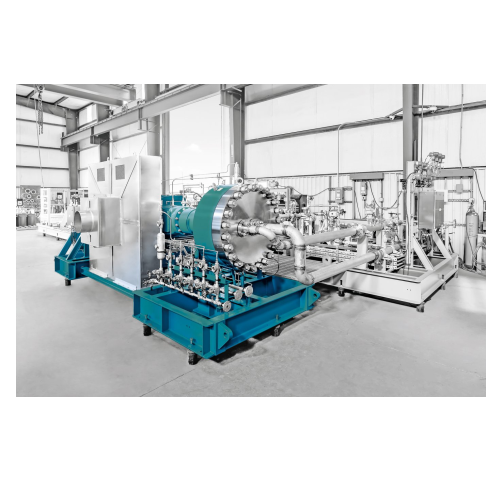

Industrial diaphragm compressor for high-purity applications

Experience reliable and contamination-free gas compression with minimal wear, ensuring optimal handling of explosive, toxic, and expensive gases while maintaining high-purity standards across your production line.

Compresses High-Purity and Sensitive Industrial Gases

The NEA|HOFER MKZ Diaphragm Compressor from Neuman & Esser offers reliable, oil-free compression for high-purity and sensitive gas applications. Utilizing a leakage-free diaphragm design, it excels in compressing hydrogen, helium, and other specialty gases in industries such as renewable energy and fine chemicals. The compressor supports continuous and automatic operations, offering discharge pressures up to 43,511 psi (3,000 bar) with stage pressure ratios up to 7. It integrates smoothly into existing systems with options for base frame mounting and includes pulsation dampers, coolers, and operational controls. Its hermetically sealed system eliminates technical abrasion, extending service life and ensuring safety in handling explosive and toxic gases. The equipment adheres to major compliance standards, including the European Machinery Directive and explosion-proof certifications. Each unit is factory-tested for performance, providing documentation of operational data. Optional customization and engineering support are available to meet diverse industrial requirements.

Benefits

- Ensures ultra-clean operations with oil-free, abrasion-free gas compression.

- Enhances safety in industrial settings by preventing leaks of toxic or explosive gases.

- Minimizes maintenance with a hydraulically-actuated diaphragm and hermetic sealing.

- Adapts to diverse industrial needs with customizable installation options and configurations.

- Complies with stringent industry standards, ensuring regulatory adherence and operational safety.

- Applications

- Expensive gases, Oil and gas industry, High-purity gas applications, Fine chemicals, Green gas industry, Explosive gases, Hydrogen economy, Renewable energies, Toxic gases, Industrial gas processing

- End products

- Chlorine for water treatment, High-purity gas mixtures, Monosilane for semiconductors, Ethylene for plastics, Toxic gas handling systems, Specialty gas packaging, Fluorine chemicals, Hydrogen fuel, Explosive gas containment, Renewable energy storage gases, Helium tanks, Pure argon gas cylinders, Process gases for chemical synthesis, Nitrogen trifluoride for electronics

- Steps before

- Hydrogen Production, Gas Processing, Site Evaluation, Feasibility Assessment, Construction, Gas Mixture Preparation

- Steps after

- Gas Storage, Continuous Process Feeding, Circulating Gas Compression, Commissioning, Gas Trading

- Input ingredients

- hydrogen, helium, argon, ethylene, fluorine, hydrogen sulfide, chlorine, monosilane, nitrogen trifluoride

- Output ingredients

- compressed gases

- Market info

- Neuman & Esser Group is known for its expertise in manufacturing compressors and grinding systems. They hold a strong reputation for providing durable, high-quality engineered-to-order equipment, particularly in the oil and gas, chemical, and energy industries.

- Discharge Pressure

- Up to 43, 511 psi (3, 000 bar)

- Stage Pressure Ratios

- Up to 7

- Number of Stages

- Up to 4 stages

- Leakage Rates

- 10^-4 mbar l/sec (up to 10^-6 mbar l/sec on request)

- Cooling Method

- Water cooling

- Automation

- Automatic shutdown in case of diaphragm failure

- Compliance

- EC-Machinery Directive 2006/42/EC

- Pulsation Dampers

- Included

- Hermetic Separation

- Between gas and oil chamber

- Material Compatibility

- Hydrogen, helium, argon, ethylene, fluorine, hydrogen sulfide, chlorine, monosilane, nitrogen trifluoride

- Compression Type

- Oil-free, diaphragm separation

- Leakage Rate

- 10^-4 mbar l/sec (up to 10^-6 on request)

- Purge or Buffer Gas Requirement

- Not required

- Service Life

- Long, hydraulic actuation

- Cooling Method

- Water cooling

- Automatic Shutdown

- Upon diaphragm failure

- Discharge Pressure

- Up to 43, 511 psi (3, 000 bar)

- Stage Pressure Ratios

- Up to 7

- Number of Stages

- Up to 4 stages

- Installation Type

- Foundation-free installation

- Piston Speed

- Low for wear resistance

- Explosion Proof

- Complies with European Directive 2014/34/EU

- Abrasion resistance

- technical abrasion-free compression due to static seals

- Corrosive resistance (e.g. acids)

- Suitable for compressing corrosive gases like chlorine

- Density/particle size

- N/A

- Cleanability

- Leakage-free operation suitable for high-purity applications

- Footprint

- Foundation-free installation

- Stages

- Up to 4 stages

- Piston Speed

- Low piston speeds

- Cooling Type

- Water cooling

- Mounting

- Base frame

- Diaphragm Head

- Hydraulically actuated

- Safety Features

- Automatic shutdown in case of diaphragm failure

- Control panel type

- Manual / Automatic

- Integration possibilities

- With auxiliary equipment / standalone

- Drive type

- Crank drive

- Cooling option

- Water cooling

- Additional equipment

- Pulsation dampers / coolers / fittings

- Foundation requirements

- Foundation-free installation