Making Rice Krispies

Find innovative production technology for making rice crispies and connect directly with world-leading specialists

From Asia to America, different forms of puffed rice bars - or as known as Rice Krispies - are enjoyed in diverse forms. Puffed rice bars or popped rice bars are made of puffed rice, sugar (or sweetener that works as a binder), additional flavorings such as vanilla or chocolate, and perhaps different sorts of grains and nuts.

Select your rice crispies process

Tell us about your production challenge

Set up your puffed rice bars production line

To make puffed rice bars, you first need to puff the rice. First, fresh rice is harvested and goes through the cleaning process. Then, the milling machine removes the bran and germ of rice. “Puffing” or “popping” the rice simply means the expansion of rice kernels by heating them under high pressure with some steam. This is because rice is naturally quite dry, compared to other grains such as corn kernels. When rice kernels are conditioned with moisture, oil can be added and put in the oven.

As the more common industrial method, you can use a puffing gun instead of an oven for this process. The benefit of using a puffing gun is that the moisture level and pressure level – often adjusted to 200 psi (1,400 kPa) – are more precisely controlled. The way how this machine works is that the pressure is abruptly released and the pressure left in the kernels causes the puffing of the rice. As the result, the fluffy and spongy texture of puffed rice is produced. This puffed rice is not only used for making puffed rice bars but also is considered as ready-to-eat cereal or snacks as a semi-end product and animal feed.

When the puffed rice is ready, they are ready for the mixing process. Before mixing, the first sugar or sweetener of your choice should be boiled and turned into liquid form. For this process, you will use a sugar boiler or cooker. Then, this liquified sweetener, which acts as a binder and puffed rice will be poured into a mixing machine. Here, depending on the type of puffed rice bar you would like to make, you can add nuts or bits of chocolate. When the mixture is well combined, they are put into forming machine. An ax of the forming machine cuts the continuous sheet of puffed rice mixture into a uniform shape. At this point, you can choose to go through the enrobing process – putting chocolate or other coatings on the bars. If the bars are coated, they have to take a moment to cool down, then these bar goes into the packaging machine.

Puffed rice bars = Rice Krispie Treats?

When we are talking about puffed rice bars, we use the term “Rice Krispies Treats” – driven from a Kellogg’s particular product – interchangeably as a synonym. Of course, they are both considered puffed or popped rice bars in a big category, however, technically, they are different products. Due to the difference in the ways the rice is prepared, they present you distinctive texture and feeling of rice; puffed rice is rather spongy and Rice Krispies is crunchy. This is because the rice grains of Rice Krispies are prepared with a sweetening, drying, rolling, and cooling process before the puffing, which does not happen to regular puffed rice.

Another difference is that Rice Krispies are popped in the oven with oil, instead of a popping gun. Also, popped rice of Rice Krispies treats is mixed with butter and marshmallow instead of simple sweeteners such as sugar or honey. Due to these traits, Rice Krispies Treats are often called “marshmallow bars” or “marshmallow treats”.

From the Asian market to the European and American market

Puffed rice bars traditionally have been made and eaten in Asia, specifically in East Asia, for many centuries. The history goes back to even the 12th century; this trace of puffed rice was written in the book of the Song Dynasty in China. Traditionally, the rice was puffed in a pot with a bit of oil, and they were molded with a liquified sweetener such as rice syrup. Depending on the preference sometimes, the producers would incorporate peanuts, sesame, or pumpkin seeds. Even to this day, most of the puffed rice bars produced on an industrial scale in the East keep this simple form of puffed rice and sweetener combination. A large number of people in the countries like China, Korea, Japan, Taiwan, and other Asian countries still enjoy them.

Since the 20th century, the puffed rice had appeared in the European and American market. Generally, the puffed rice bars have been divided into two kinds in the market – one that is considered a dessert like the Rice Krispies Treats or one that is considered a healthy breakfast option like puffed rice cereal bars. For the former, fat and sugar content is higher than the Asian puffed rice bars as butter and marshmallow are incorporated in the mixing process. The latter, branded as the healthier product, includes more grains, nuts, or chocolate bits, sometimes covered with chocolate or yogurt coatings by going through enrobing process. It is interesting to see how the Western market prefers more diverse ingredients in their puffed rice bars and the Asian market sticks to the simple form of puffed rice bars coming down from the tradition.

Which rice crispies technology do you need?

High pressure extruder for expanded snacks

Enhance your snack production with precise control over texture and shape throu...

Extruder for pliable mixes in industrial applications

Achieve precision in creating diverse extruded food products with t...

Wafer sheet cream application system

Achieve precision in cream application with high-capacity, continuous film spreading, ...

Industrial pellet fryer for high quality snack production

Optimize your snack production line with precise control over ...

Pellet snack fryer

Expand your snack range with precision by frying pellet snacks using a patented process that ensures unifo...

Single-screw extruder for pre-gelatinized materials

Streamline your production of snack pellets and instant noodles with ...

Single screw extruder for pet food and aquatic feed

Maximize production capacity and optimize product quality with advanc...

Industrial breadchips cutting solution

Achieve precise, high-speed slicing of bread-based strands into thin, uniform chips ...

Batch mixers for raw material preparation in extrusion processes

Optimize your extrusion process with precise raw materi...

Food product extruder for low to high capacity production

Optimize your snack production with versatile extruders that e...

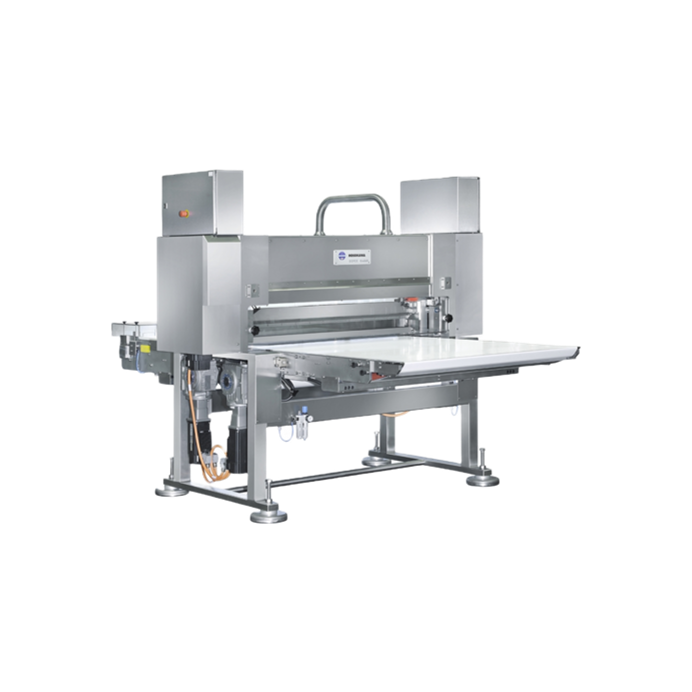

Guillotine cutter for confectionery

Confectionery products such as marshmallows, licorice candies, and fudges come out of e...

Industrial guillotine machine for extruded foods

Textured vegetable proteins made from soy, wheat, and oats are extruded i...

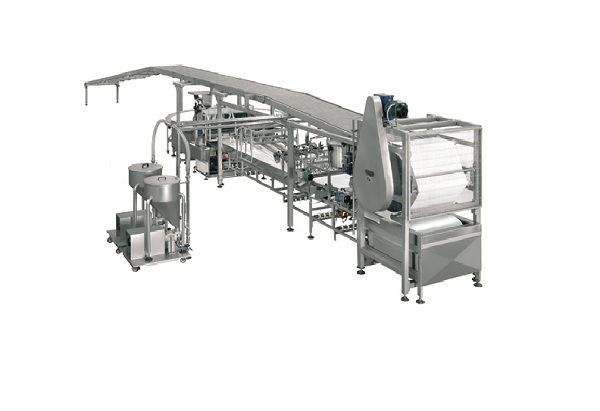

Entry-level cereal bar making machine

Cereal and grain bars are increasingly popular, both as snack foods and as functional...

High capacity freezer for food

Freezing is one of the most important industrial methods for the long-term preservation of fo...

Line for sponge cakes production

Bringing together a wide range of process machinery to develop a production line for sponge...

Cake ultrasonic cutter

Some cake items you may wish to cut can feature substantial amounts of cream. But that cream could sme...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

Hygienic and fully-welded spiral freezer for food

Food freezers are often the last step in the food production chain. The...

High capacity spiral cooler for food

Cooling baked goods and food products can be problematic for sliced baked goods. A cru...

High speed waffle decorator

In the past, there were not many ways to make waffles or wafers colorful, tasty, and attractive ...

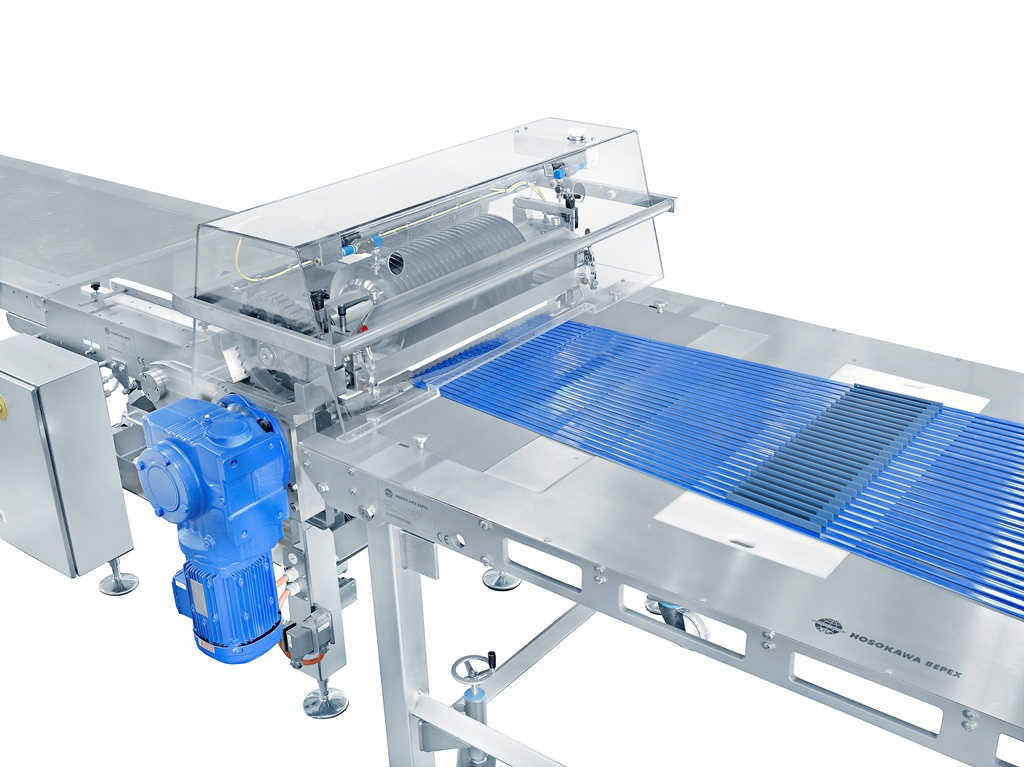

Longitudinal strand cutting machine

Cut continuous slabs of your ingredient mix into spaced strands for further processing ...

Entry-level automatic cereal bar machine

Start up your manufacturing of cereal bars or produce smaller batches to test and ...

Slab forming machine

Turn the mixture of your ingredients, into continuous slabs for processing into bars, stands, or other s...

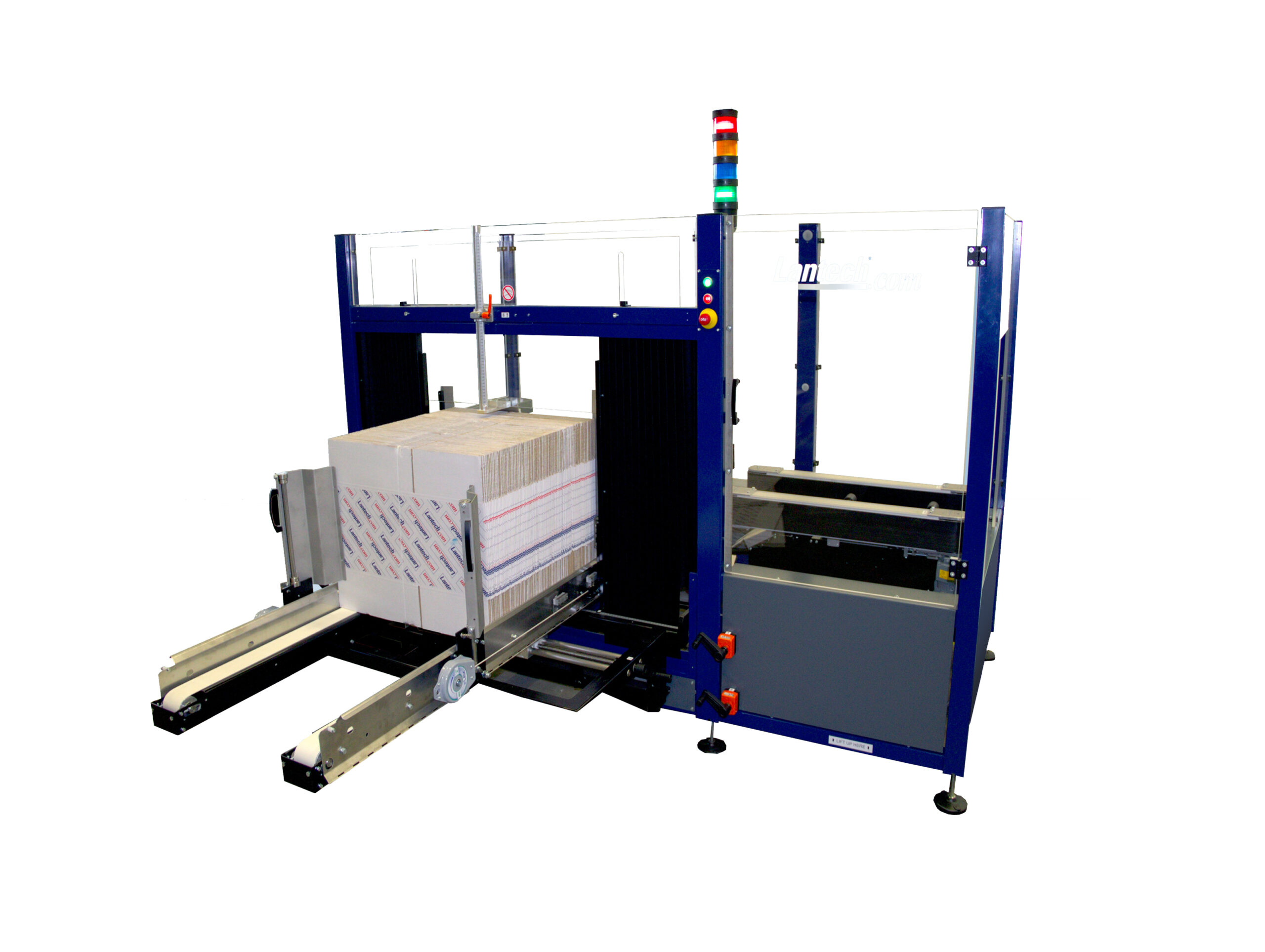

Case erector

To overcome common cases of manufacturing variations and optimize your packaging line, you need to be able to cou...

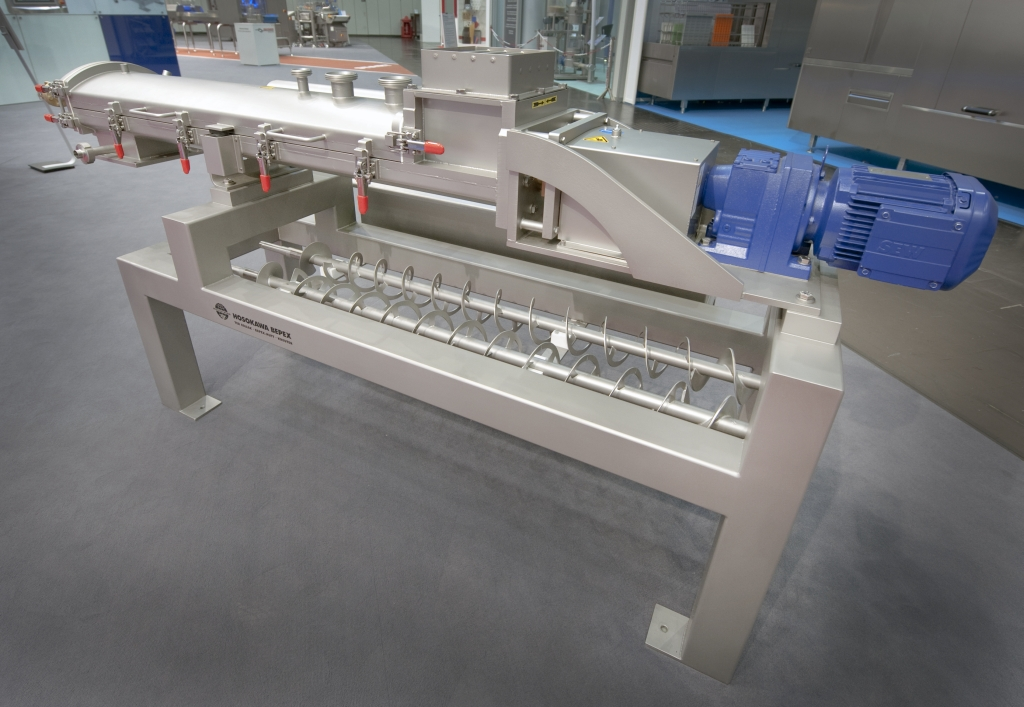

Continuous caramel mixer

Mix your recipe’s ingredients in preparation for further processing. This is a continuous mixe...