Making Cashew Milk

Find innovative production technology for making cashew milk and connect directly with world-leading specialists

Creamier, sweeter and versatile are the key adjectives when talking about cashew milk, especially compared to other plant-based milk. Additionally, it is rich in vitamins B and D, as well as essential minerals. Being a blend of cashew kernels and water, the cashew nut milk processing equipment includes a peeling and washing machine, a colloid mill, and a blending tank.

Stories about cashew milk

Tell us about your production challenge

The first steps: from raw cashew apple to a slurry

Having cashew kernels and water as the main ingredients, the initial step in cashew milk production is obtaining the nuts. Technically a seed, raw cashews must be detached from the “cashew apple”, which is usually done manually. However, due to the cashew shell being filled with toxins, the process must be executed carefully. Once the cashews are prepared, cashew milk processing can begin by soaking the nuts in hot water to remove the hull.

The hull is peeled in a drum-type peeling and washing machine which can also be used for other nuts. When the hull is removed, cashews are soaked again, this time in cold deionized water. After the soaking process, the nuts are rinsed in stainless steel washing tank and processed into a slurry with the help of either a colloid mill or superfine grinder.

Cashew nut milk processing equipment and production: transforming slurry into a beverage

The cashew slurry must be filtered by the vibrate screen filter in order to remove all present solids and unwanted substances. To turn the slurry into a beverage, the slurry is added to the key part of the cashew nut milk processing equipment – the blending tank. In the blending tank, the slurry is liquefied by adding pure RO water. This step is also important to achieve the desired consistency, flavor and nutritional benefits. Therefore, ingredients such as salt, sugar (around 3%), vitamins, gum, and lecithin can be added.

For cashew nut milk, the ideal ratio of nut to water is 1:10. Furthermore, as plant-based proteins can be hard to digest, enzymatic hydrolysis, which improves digestibility, is an essential step in production. To secure maximum safety, cashew milk is both homogenized and pasteurized. Pasteurization is done to sterilize the product and ensure safe shelf life. Finally, the sterilized milk must be degassed to remove the excess air.

Food safety and high-pressure processing

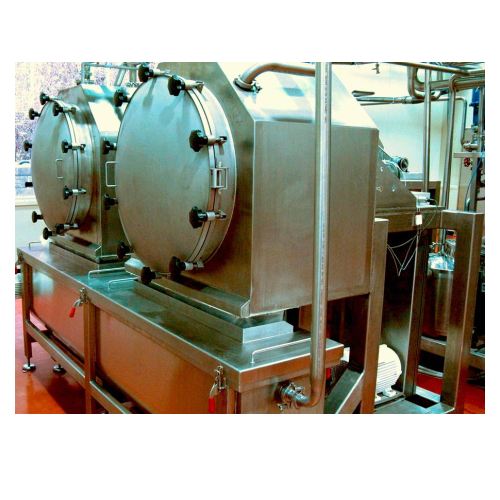

High-pressure processing is an alternative to securing food safety while minimizing the need for additives and preserving the nutritional value of products. Instead of additives and heat, it uses cold high-pressure, which destroys any pathogen present in the product. Alternative to pasteurization, the finished and packed product is placed into a wire wound vessel filled with pure, cold water, then pressurizing the water and contents through specially designed intensifier pumps to reach as high as 6,000 bars.

Under this amount of pressure, products will compress about 15% of their volume; therefore, the packaging must be made of flexible materials. The shelf life of cashew nut milk that underwent HPP is comparable to pasteurized cow milk.

While the HPP treatment alone did not affect the proteins, it significantly increased the peptide content of the cashew milk. It also increased the hydrolysis of the cashew milk, but the foaming capacity remained relatively the same. Although it is allowed, HPP of plant-based products in the European Union is strictly regulated.

Beyond plant-based milk: cashew yogurt

Due to its high crude protein percentage (16.8%), cashew yogurt is an excellent vegan alternative to dairy yogurt. Cashew yogurt is produced directly from cashew milk. To transform the beverage into food, the milk must be inoculated with the bacteria Streptococcus thermophilus. The product is then left to coagulate for 7 hours at 45°C. Once the yogurt is produced, it must be soaked in a cold bath overnight. Considering quality, content and viscosity, and no difference in taste and flavor with commercial yogurt, cashew yogurt is an ideal alternative for vegan and lactose-intolerant individuals.

Cashews vs. Almonds: which milk is greener?

Aside from being suitable for vegan and lactose-intolerant populations, plant-based milk is marketed as an environmentally-friendly alternative to regular dairy. In this context, comparing cashew and almond milk is interesting due to their similarities. While the cashew industry has a bad reputation due to poor working conditions, the almond industry relies on unsustainable mass pollination. However, the former can be avoided, while the latter can not.

In addition, almond production requires 12% more water, which mostly relies on underground aquifers, while a cashew tree gets 90% of the needed water from rain. Both almond and cashew trees absorb carbon dioxide, and it is unclear which milk production has a lower carbon footprint, but data shows that almond milk clearly wins over oat milk, soy milk, rice milk, and of course, cow milk.

Processing steps involved in cashew milk making

Which cashew milk technology do you need?

Almond milk production system

Streamline your plant-based beverage production with a comprehensive system designed to finely...

Dairy alternative production technology

Transform your production line with efficient dairy-alternative technology, enablin...

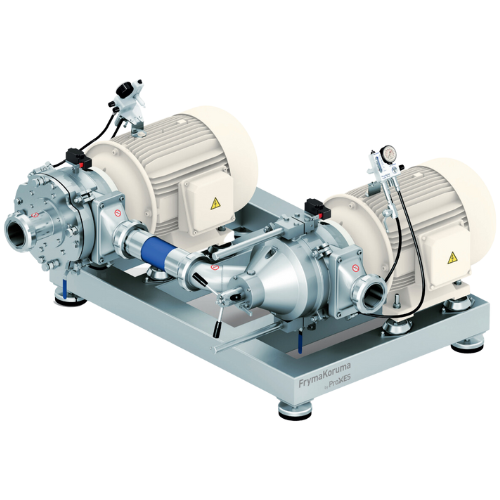

Colloid mill for emulsifying and wet milling applications

Achieve precise mixing and grinding with our colloid mill, des...

Hammermills for grinding tough products

Optimize particle size reduction with precision-designed hammermills that efficient...

High-speed vacuum blender for commercial use

Achieve optimal blending with cutting-edge vacuum technology, ensuring vibran...

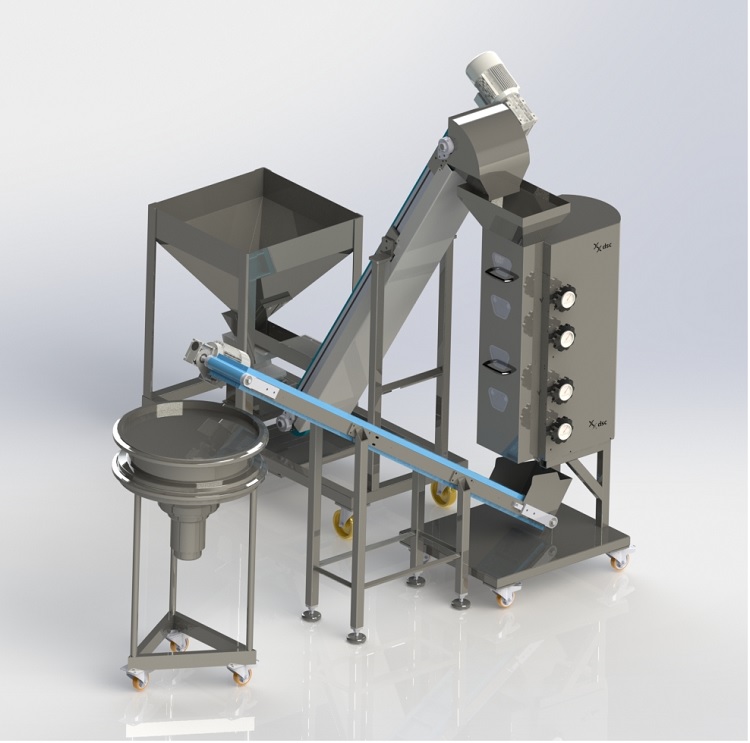

High-precision sorter for nuts, coffee, seeds, and grains

Achieve unrivaled accuracy in sorting nuts, seeds, and grains ...

Industrial grinder for plant-based beverages production

Achieve optimal particle size for seamless integration with your ...

Hydrolysation tank for plant-based beverage production

Ensure optimal hydrolysis conditions for plant-based beverages wit...

High-precision decanter for plant-based beverages

Enhance your plant-based beverage production with a decanter engineered...

Double decanter for plant-based beverage extraction

Maximize protein yield and enhance extraction efficiency in your plan...

Industrial grinder for plant-based beverages

Ensure optimal particle size for hydrolysis in plant-based beverage productio...

Microfiltration system for dairy and plant-based applications

Enhance your production capacity and reduce waste with adv...

Energy efficient grinder for plant-based milk

Buying pre-processed materials, such as flour, and handling and dispersing t...

Automatic FIBC Sealing machine

When sealing large bags containing bulk products, a sealer must be reliable to keep the MAP s...

Sensor for Modified Atmosphere FIBCs

Every year, more than 200 million FIBCs are filled with food for storage and transport...

Modified Atmosphere Big Bags

Manufacturers requiring big bag packaging have specific sizes, shapes, and material requirement...

Water treatment for beverage preparation

Water is one of the main ingredients in producing juices and other beverages. If i...

Continuous sterilizer for milk beverages

An important goal of heat processing in the manufacturing of milk beverages is to ...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Automatic bottling machine for beverage

One of the biggest challenges when bottling beverage drinks is that many of the bot...

Air knife system for bottling lines

Wet containers are unacceptable and can be problematic in the food and beverage industr...

CIP system for beverage

Clean-in-place operations are a mandatory part of food and beverage processing which cannot fail. How...

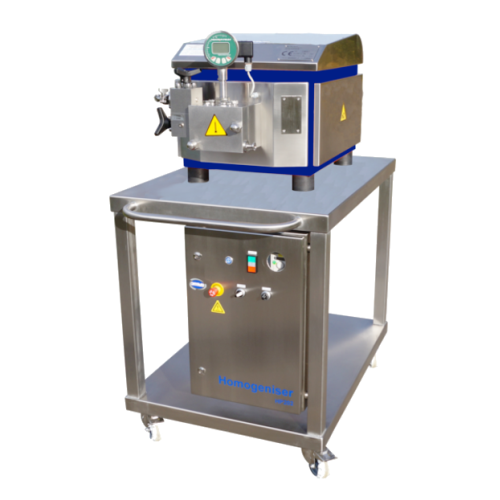

High pressure electric laboratory homogenizer

It’s vital that small units for experimentation can scale up with 100% accur...

High pressure pilot homogenizer

Biotech and pharmaceutical development programs often require a mixing method that achieves ...

High pressure industrial homogenizer

For any industrial pharmaceutical process that relies on high pressure homogenization ...

Infrared rotating drum dryer

Traditional drying methods are often slow and can actively damage ingredients, reducing the fin...

Air knife dryer for bottles

When filling glass bottles during beverage production, the cleaning and filling processes often ...

Entry-level infrared nut drying machine

For small scale production of cocoa beans and nuts, the use of traditional toasters...

Small scale nut chopping machine

Many confectionery and bakery products use nuts as a key ingredient or decoration. The abil...

Small scale linear sieve for nuts

Removing dust and grading grains is an important part of producing a high quality chopped...

Vibrating sieve for liquid solid separation

Many industrial processes require the efficient separation of solids from a sl...

Versatile bottle sorting system

Quality bottle sorting machine and inspection system which can be put to use not only after ...

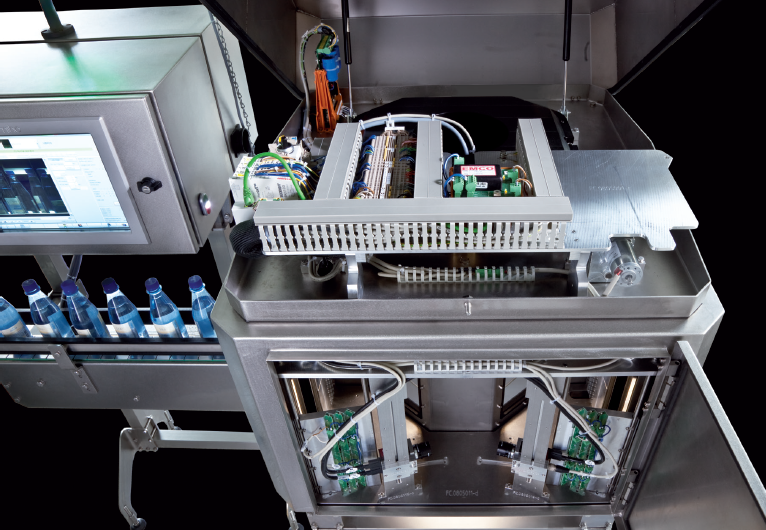

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

Industrial nut grater

Pressure from the grinding process can cause damage to food products as well as induce unwanted heating...

Nut dicer

Dicing nuts can generate a large volume of wasteful and messy powdered nut residue.

High-precision X-ray fill level controller

High-speed, high precision X-ray system to inspect containers that are difficul...

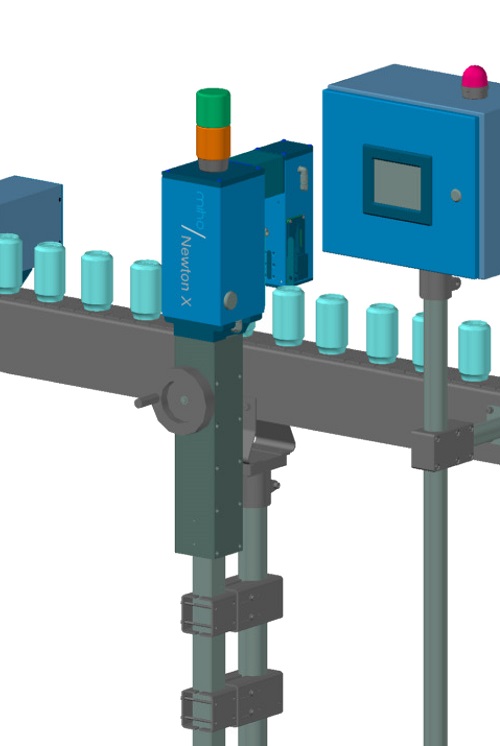

X-ray fill level controller

For containers that are difficult to see through, such as cans or cartons lined with aluminium, ...

High-frequency fill level controller

In terms of high-frequency technology, the fill level detection is considered a standa...