Find technology for processing algae

Find innovative production technology for making algae and connect directly with world-leading specialists

The essence of the oceans plays a role in sustainable food production and is an often overlooked superfood. Compared to traditional crops, algae requires minimal land and resources. Processed into food powders like spirulina or chlorella or into seaweed snacks, algae is considered to be one of the foods of the future. It provides you with vitamins, minerals, and proteins and assists the world in food security concerns. It is a popular ingredient in the supplement and cosmetics industry too.

Tell us about your production challenge

Infuse or encapsulate algae into dietary supplements or skincare formulations

Selecting the optimal method for integrating algae into industrial processes is paramount. You can opt for infusing algae extracts into product formulations during manufacturing. This process entails thorough blending of algae extracts with other ingredients to ensure homogeneous distribution throughout the product matrix. Subsequently, you must process the mixture further according to the specific requirements of the end product, whether it’s a face cream or a nutraceutical.

Alternatively, you can choose to encapsulate of algae extracts within product matrices. Through precise injection or deposition techniques, you can strategically embed algae-derived compounds within the product, enhancing functionality and value. This encapsulation method not only preserves the integrity of algae-derived elements but also facilitates controlled release, optimizing their efficacy in functional foods, supplements or cosmetics.

Dry your algae to make snacks or powders

You can also produce food from algae, the most evident examples are nori, wakame, seaweed snacks and spirulina. The first important step is washing your algae, to ensure there are no impurities in your produce. Drying is a critical step in algae processing to remove moisture and enhance shelf stability. You can air dry, spray dry, freeze dry, or drum dry your algae, depending on the desired product characteristics and processing capabilities. For making spirulina or chlorella powders, opt for spray drying. For nori and seaweed snacks, air drying is the best solution.

Process your algae further

After drying, your algae must undergo further processing to refine its texture and particle size for snacks. You can mill or grind it into finer particles when you are making bars or powders. Or extrude it into shapes like crisps or puffs for enhanced palatability. There is more, you can even granulate it for improved handling in mixes or baked goods, algae’s applications and processes are endless.

Flavor development is an important aspect of algae snack production, where you can test different seasoning blends. Most well-known combinations are sweet chili, wasabi, garlic, or BBQ. For that you’ll need precision dosing equipment and mixing technologies to ensure uniform distribution of flavorings and seasonings across the product.

Pack your snacks safely to preserve the delicate texture

Packaging plays a crucial role in preserving the freshness, flavor, and quality of algae snacks during storage and transportation. You might need automated filling machines, sealers, and labeling systems that are capable of handling high volumes and maintaining product integrity. Your packaging materials should be selected based on barrier properties and moisture resistance. You should also take sustainability considerations into account to make sure that the packages don’t end up in sea to pollute your future produce!

Processing steps involved in algae making

Which algae technology do you need?

Indoor microalgae cultivation technology

Enhance sustainability and productivity in microalgae cultivation with a vertical ...

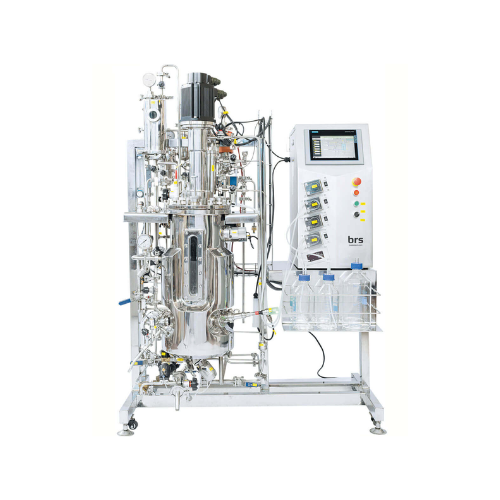

Compact fermentor for research and scale-up studies

Optimize your bioprocess development with a desktop fermentor that of...

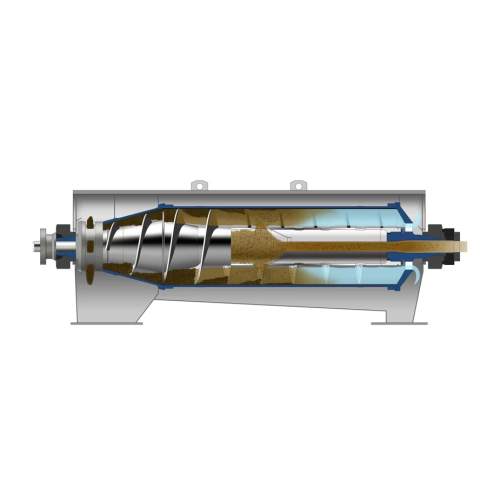

Decanter centrifuge for soft sediment separation

For operations dealing with soft, easy-flowing sediments, ensuring effici...

2-phase separator for clarifying liquids

Efficiently refine and clarify liquids while minimizing waste. This 2-phase separa...

3 phase decanter centrifuge for industrial separation

Optimize your production line with efficient three-phase separation...

Decanter centrifuge for wastewater treatment

Effectively manage waste streams and enhance resource recovery with this high...

Industrial nozzle separator for high solids concentration

Optimize your production with high-performance nozzle separato...

Microalgae photobioreactors for bioenergy production

Optimize your microalgae’s growth and conversion processes wit...

Pulsed electric field system for olive oil processing

Enhance extraction efficiency and product quality with this advance...

Industrial pulper for fresh produce

Achieve ultra-fine purees and pastes with this high-speed industrial pulper, designed t...

Pilot fermentors for biotech processes

Optimize your pilot-scale production with versatile fermentors and bioreactors desig...

Flash dryer for corn starch

Reduce energy consumption and maintain product quality with efficient drying solutions designed ...

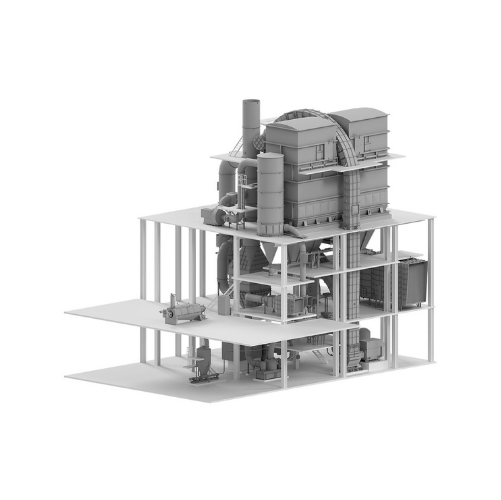

Microalgae cultivation infrastructure

The microalgae cultivation infrastructure streamlines your production with integrated...

Microalgae cultivation system

Boost your microalgae production with an advanced cultivation module that optimizes photosynth...

Pre-culture and laboratory systems for microalgae cultivation

Enhance your microalgae cultivation with precise control a...

Lab-scale microalgae cultivation system

Achieve precise control of microalgae cultivation with optimized growth conditions ...

Laboratory-scale microalgae cultivation system

Harness precise cultivation capabilities for microalgae with advanced photo...

Laboratory microalgae cultivation system

Elevate your lab-scale microalgae production with a system designed for precise cu...

Autoclavable photobioreactor for microalgae and bacteria cultivation

Optimize the growth of phototrophic organisms with...

Industrial seaweed drum dryer

Optimize your seaweed and algae processing with an advanced drum drying solution that effectiv...

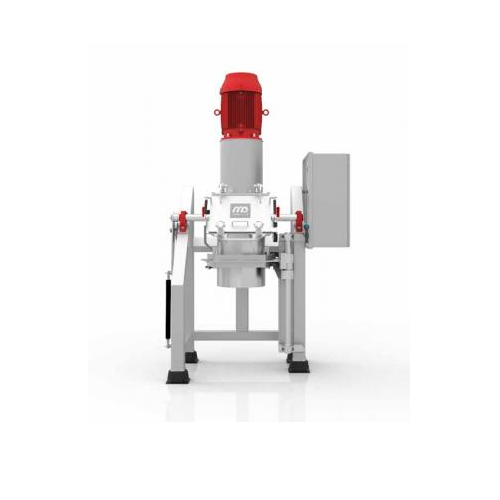

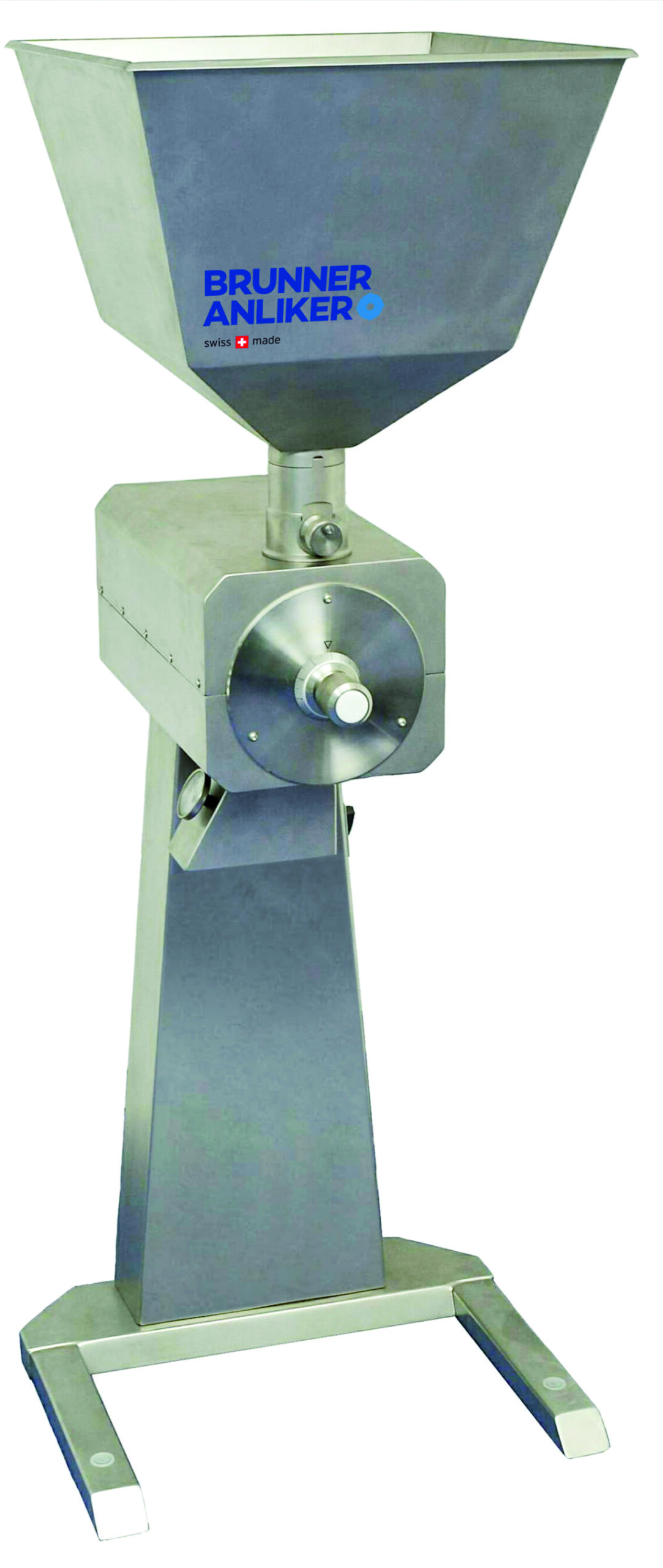

Semi-automatic seaweed grinder for efficient algae processing

Optimize seaweed processing with this stainless steel grin...

Customized conveyors for seaweed harvesting

Streamline your seaweed processing operations with versatile conveyor solution...

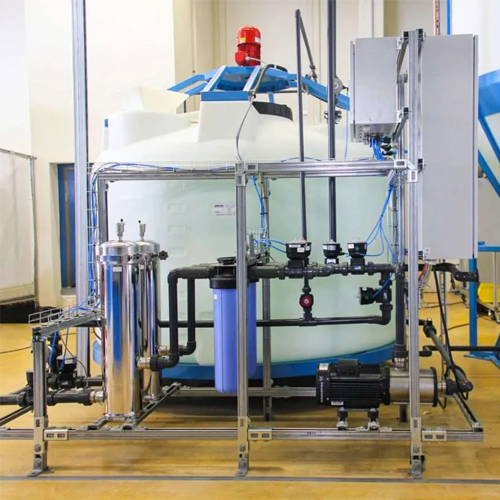

Algae harvest and concentration filtration system

Optimize algae production by seamlessly integrating this filtration sys...

Feed system for pilot-scale microfiltration and ultrafiltration applications

Optimize your small-scale production with...

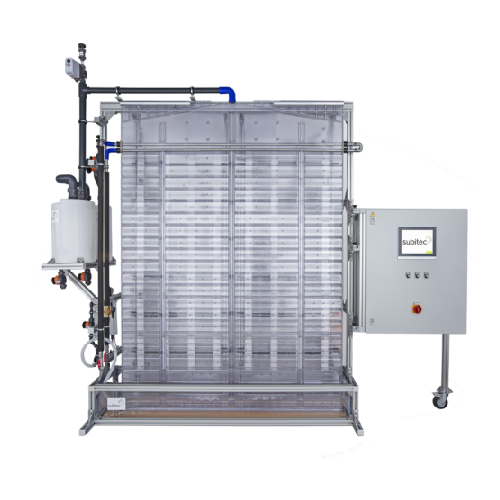

Lab-scale filtration system for micro- and ultrafiltration

Simplify complex microfiltration and ultrafiltration tasks wi...

Benchtop membrane filtration for process development

Eliminate fouling and achieve precise separation with a benchtop fil...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Waste to energy anaerobic digestion system

The food industry produces tremendous amounts of waste at food production facil...

Grinder for spices and coffee

Gentle grinding of coffee down to all grades from coarse to fine requires high precision proce...

Sampling probe for bioreactor samples

In biopharmaceutical and chemical industries, sampling is vital to develop, maintain,...

Automatic sampling system for bioprocess monitoring

An accurate, automated sampling of cultures is a key requirement in t...

Entry-level automated online sampling system

An accurate and sterile sampling of cultures is vital throughout the biopharm...

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

Hygienic belt dryer

A belt dryer typically applies the product through an infeed chamber onto a perforated horizontal belt, w...