Toothpaste filling Equipment

Find innovative toothpaste filling equipment and connect directly with world-leading technology suppliers

If you think of toothpaste, the first thing that comes to mind is not the product itself but the shape of its container, the squeeze tube. The paste is dosed and then inserted correctly through a nozzle into the tubes placed on the rotary tube filler unit and moved to the sealing unit as they are filled. Once the filling is over, the machine crimps the open tube end.

Which toothpaste filling technology do you need?

Tube filling machine for cosmetics and food products

Achieve precise and efficient packaging with this advanced twin-head...

Tube filling solution for plastic, laminate, and aluminum tubes

Optimize your production line with a versatile tube fill...

Tube filling station for plastic, laminate, and aluminum tubes

Efficiently seal and fill various tube materials, ensurin...

Laboratory filling system for liquid and creamy products

Optimize your laboratory processes by precisely handling liquid,...

Automatic tube filling and closing for metal, plastic, and laminate tubes

Enhance your production efficiency with a hi...

Stick pack forming, filling, and sealing solution

Enhance packaging efficiency with a high-speed solution designed for pr...

Automatic tubefiller for food and dairy products

Achieve precise dosing and seamless tube filling with high-speed efficien...

Automatic tube filling and closing system

Enhance production efficiency with a high-speed tube filling and closing system ...

Semi-automatic tube filling and closing system

Achieve precise filling and secure closing for diverse tube types, optimizi...

Automatic tube filling and closing solution

Optimize your production line with a high-speed machine for precise tube filli...

Automatic tube filling and closing system

Enhance your packaging efficiency with a high-speed tube filling and closing sol...

Tube filler & sealer for metal and plastic tubes

Streamline your production line by efficiently filling and sealing metal ...

Efficient tube filler and sealer

Optimize your production line with a semi-automatic tube filling and sealing solution, desi...

Tube filling and sealing for metal and plastic tubes

Achieve precise tube filling and sealing with high speed and efficie...

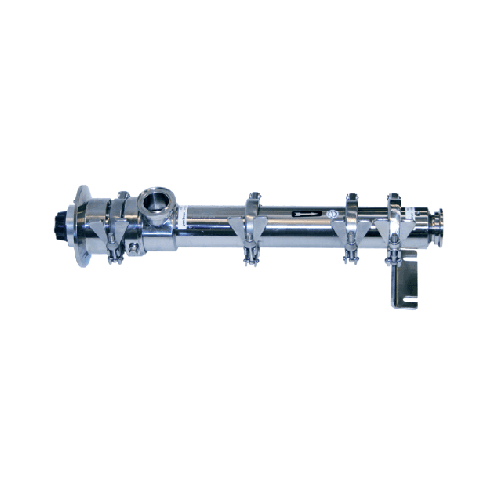

Dosing and filling pump for liquids and pastes

Achieve precise dosing and filling of liquids and pastes with compact, hygi...

Dosing and filling pump for hygienic applications

Optimize your production line with this dosing and filling pump, design...

Automatic tube filling for multi-color products

Achieve precision in multi-color product packaging with seamless co-extrus...

Automatic tube filler for multi-color coextruded products

Achieve precise dual- or tri-color product designs with except...

Automatic tube filling for coextruded products

Maximize efficiency in high-volume production with precision co-extruding c...

Automatic tube filling solution for high-volume production

Effortlessly streamline your production with this high-speed ...

Automatic tube filler for co-extruded products

Achieve precise multicolor co-extrusion filling with high-speed accuracy, o...

Automatic tube filling solution for medium to high volume production

Boost your production line efficiency with a robus...

Small batch tube filling system for metal and plastic tubes

Optimize your small-batch production with precise tube filli...

Flowmeter filler

For larger production runs of food, non-food and cosmetics industries, where accuracy and volume of filling i...

Compact monoblock filler

Filling and capping bottles and pots for food, chemical and cosmetics industries using separate mach...

Loading cassette for a tube filler

High performance tube-filling machines are used in the pharmaceutical and cosmetic indus...

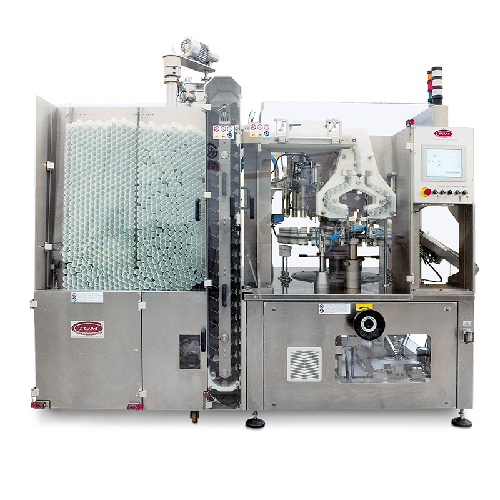

High speed automatic tube filler

For high-volume lines filling pharmaceutical, cosmetic or food products into tube container...

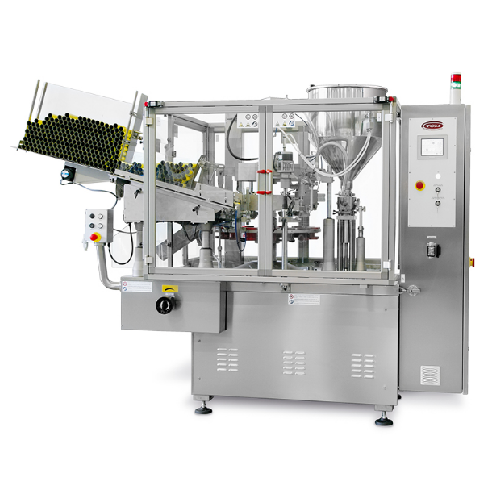

Medium speed tube filler and sealer

For scale-up filling of tube packaging for pharmaceuticals, cosmetics and food products...

Medium and high speed range automatic tube filler

When scaling up production of pharmaceutical, food or cosmetic products...

Low speed tube filler

Increasing numbers of products in the pharmaceutical, cosmetic and food industries are delivered in fle...

A two-component filling application tube filler

A wide variety of pharmaceutical, cosmetic and food products require tube-...

Servo controlled filler

For food and non-food liquid products that are high foam or have a high viscosity a specialist fillin...

Horizontal flat pouching line for liquid soaps

Streamline your liquid product packaging with a dual-lane flat pouching lin...

Paper forming technology for sustainable packaging

Elevate your product’s sustainability with advanced paper formin...

Hig Speed Tube Cartoner

Achieve seamless integration into your high-speed packaging line with a cartoning solution that ensur...

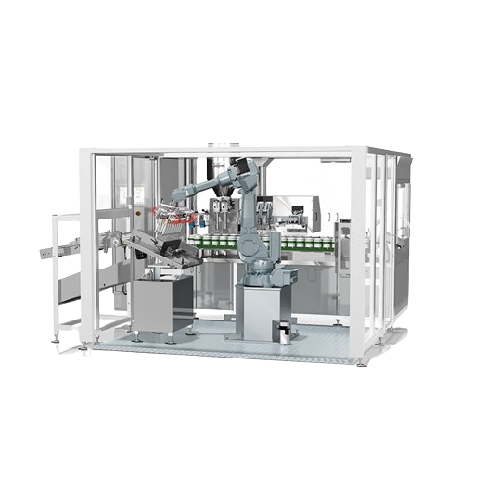

Pick & place robot for packing tubes in boxes

Efficiently streamline your packaging line with this compact case packer, de...

Horizontal cartoner for diverse industries

Streamline your packaging process with precise cartoning capabilities, effectiv...

Integrated packaging system for cement and building materials

Streamline your packing operations with a fully enclosed s...

Stainless steel buffer tanks for food, pharma, and cosmetics

Ideal for maintaining process fluidity, these stainless ste...

Horizontal flat pouching system for liquid soaps

Optimize your liquid packaging with high-speed, continuous operations tha...

Dosing pump for liquids and pastes

Achieve precise dosing and filling of liquids and pastes with flexibility in dosing volu...

Single head capper

For the stand-alone capping of bottles of up to 30 litre capacity for smaller-scale production you need a ...

Top load cartoning system for pharmaceuticals

Optimize your packaging line with precision top-load cartoning, designed for...

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

Intermittent stick pack machine for pharma and healthcare

Looking to streamline your packaging operations with high-spee...

Intermittent stick pack packaging system for pharma products

Achieve precise dosage and packaging of pharmaceutical and ...

High-speed multi-lane flat pouch packaging system

Boost your packaging efficiency with a high-speed solution designed for...

Multi-lane vertical pouching solution for pharma industry

Achieve precision and high-speed efficiency in single-dose liq...

Vacuum processing units for high-viscosity products

For manufacturers seeking to streamline production of high-viscosity ...

Continuous cartoning solution

Enhance your production line with efficient high-speed cartoning, designed to streamline packa...

Stand-up pouch packaging for various industries

Elevate your packaging capabilities with a high-speed horizontal pouching ...