Plastics recycling

Find innovative production technology for making plastics recycling and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Processing steps involved in plastics recycling making

Which plastics recycling technology do you need?

Ultrafine classifier for precise particle separation

Gain precise control over particle size with this ultrafine classifi...

2-phase separator for clarifying liquids

Efficiently refine and clarify liquids while minimizing waste. This 2-phase separa...

3-phase liquid separation solution

Achieve precise separation of liquids and solids to enhance product quality and streamli...

Centrifuge for plastics recycling

Enhance your recycling process with a centrifuge designed to efficiently separate and dew...

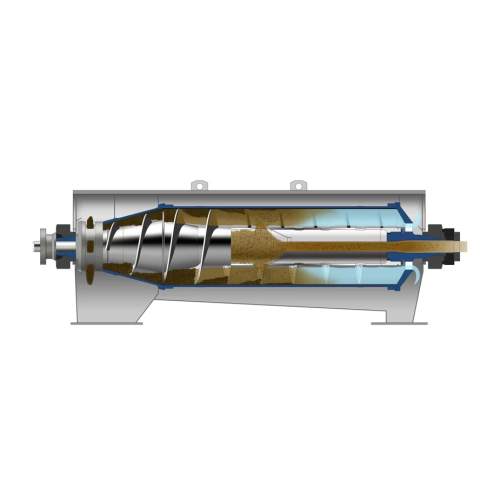

3 phase decanter centrifuge for industrial separation

Optimize your production line with efficient three-phase separation...

Decanter centrifuge for wastewater treatment

Effectively manage waste streams and enhance resource recovery with this high...

High-performance decanter centrifuge for industrial separation

Optimize your production with a centrifuge solution that ...

Industrial nozzle separator for high solids concentration

Optimize your production with high-performance nozzle separato...

Surge bins for material handling

Ensure efficient material flow and storage in your production line with surge bins that fea...

Precision feeders and mixers for plastics processing

Achieve precise blending and feeding for plastics processing with mo...

Gravimetric batch blender for plastics compounding

Achieve precise batch blending with high accuracy, ensuring consistenc...

Industrial vibratory feeder for bulk solids

Ensure precise and gentle handling of delicate bulk materials with a cutting-e...

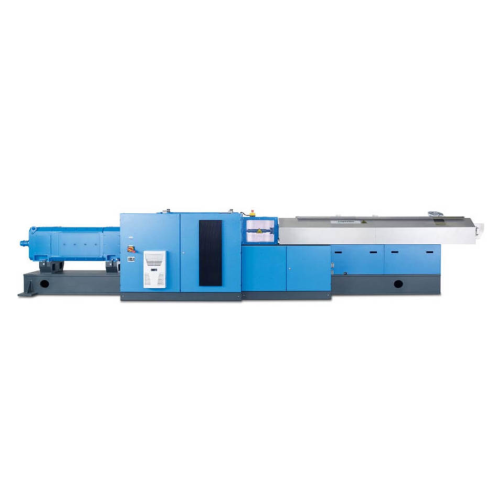

High throughput twin screw extruder for low bulk density products

When handling low bulk density materials, achieving m...

Regenerative vacuum blower for pneumatic conveying

Optimize your material handling with a compact regenerative vacuum blo...

Industrial vacuum blower for continuous pressure conveying

Optimize your production line with reliable vacuum conveying,...

Single-shaft ribbon blender for homogeneous mixing

Achieve high-quality, precise blending of delicate and temperature-sen...

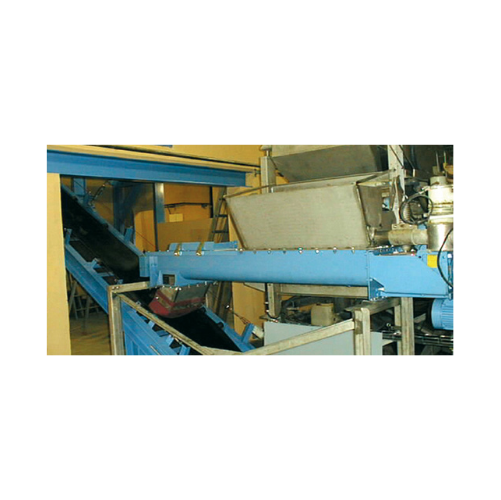

Screw compactor for wastewater treatment

Optimize waste management with a versatile screw compactor designed for efficient ...

Aerated grit chamber for wastewater treatment

Optimize wastewater treatment with effective sedimentation and de-greasing, ...

Rotary drum screens for efficient wastewater treatment

Ensure optimal separation and de-watering of solids in wastewater ...

In-channel vertical screw screen for wastewater treatment

Optimize your wastewater management with high-efficiency solid...

Combined septage receiving station for solid waste compaction

Streamline wastewater treatment by efficiently handling de...

Overflow spillway filter for wastewater treatment

Effectively manage overflow wastewater with this advanced filtration sy...

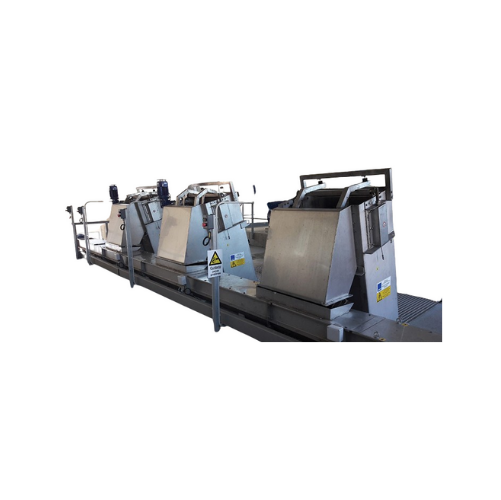

Shafted washer compactors for wastewater treatment

Effectively compact and dewater waste streams while reducing volume by...

Food-grade round dust collectors

Maintain a clean production environment with this food-grade dust collector, designed to ma...

Flanged round dust collectors for industrial air filtration

Optimize your industrial processes with a dust collection sy...

Fine belt screens for wastewater treatment

Efficiently screen and convey solids from wastewater with in-channel fine belt ...

Drum-type diverter valves for pneumatic conveying

Optimize your pneumatic conveying system by effortlessly controlling th...

Septage receiving station for septage treatment

Optimize your wastewater management by integrating a station that screens,...

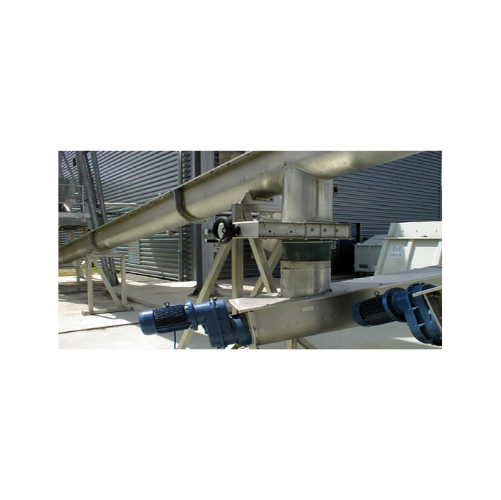

Vertical screw conveyors for sludge handling

Efficiently lift and blend sludge with minimal footprint and costs, while ens...

Externally fed drum screen for wastewater treatment

Optimize your wastewater treatment with advanced drum screening techn...

High flow rate Fibc dischargers for wastewater treatment

Optimize your material handling with efficient, dust-proof disch...

Internally fed rotating drum screen for wastewater treatment

Streamline your wastewater management with this advanced fi...

Pneumatic hammers for aiding material flow

Optimize material flow and eliminate blockages in your processing line with pne...

Penstock for wastewater treatment

Efficiently control and isolate water flow in your wastewater treatment facility, ensurin...

Rotary roller vibrators for material flow assistance

Enhance material flow efficiency in your production line with high-f...

Continuous twin shaft paddle mixers for dust conditioning

Optimize your mixing process with twin shaft paddle mixers, en...

Pneumatic linear vibrators for bulk material flow

Prevent bridging and rat-holing in your production process with silent,...

Bar screens for wastewater treatment

Efficiently remove coarse debris from wastewater streams with high-capacity sub-vertic...

Mechanical fine bar screens for wastewater treatment

Efficiently capture and remove solids from wastewater streams with s...

Sub-vertical mechanical bar screens for wastewater treatment

Optimize your wastewater treatment process by capturing coa...

Sub-vertical mechanical perforated screens for wastewater treatment

Optimize your wastewater treatment process with adv...

Cushioned pneumatic vibrators for coarse particle materials compaction

Enhance your material flow and compaction proces...

Grit classifier for wastewater treatment

Optimize your wastewater treatment process with a grit classifier that efficiently...

Screenings compactor for waste water treatment

Achieve efficient waste management by reducing the volume of screenings by ...