Making Water For Injection

Find innovative production technology for making water for injection and connect directly with world-leading specialists

If you've ever heard the acronym WFI spoken, know that we're not talking about wireless technology to connect your computer. WFI stands for water for injection, a sterile water used as a solvent to dilute other solutions for injections to the body. Traditionally, WFI was only produced through the distillation process using water for injection equipment until other methods such as reverse osmosis, electrodeionization, and ultrafiltration were developed.

Select your water for injection process

Tell us about your production challenge

Achieving high purity water through different water for injection equipment

Achieving high purity water for injection requires complex equipment that depends on the preferred method to be used. The three common methods for WFI production are multiple effect distillation, vapor compression distillation, and reverse osmosis, electrodeionization, and ultrafiltration. They all use water softening and carbon filtration as a means of scale control and dechlorination of the water source.

Starting with the multiple effect distillation method, your feedwater is preheated before going to a column containing a heat exchanger. As the feedwater is heated, the cyclone separator separates the pure steam which is then used to heat more feedwater.

The condensate of pure steam collected in the condenser that goes to the holding tank is your water for injection.

The second method is vapor compression distillation. Feedwater is preheated before going to the decarbonator which removes non-condensable gases from the feedwater. It then goes to the evaporator tubes where steam-heating coils at the bottom further heat the feedwater to convert it to vapor. A demister removes water droplets from the vapor before the vapor goes to evaporator bank where it condenses, forming distillate. This distillate is collected in a box and pumped through a cooler to produce water for injection.

The third method combines multiple processes such as reverse osmosis, electrodeionization, and ultrafiltration using different water for injection equipment such as filters and membranes. Reverse osmosis uses membranes to remove most of the unwanted molecules and particles. Electrodeionization removes positive and negative ions using electric power and is considered as a polisher after performing reverse osmosis. Ultrafiltration uses ultra-fine membrane filters to further remove contaminants.

Bacteriostatic water or sterile water for injection?

Water for injection, in general, should be pure. Though in some applications, it may be necessary to add antimicrobial agents to minimize the chance of contamination once opened. Bacteriostatic water is sterile water containing 0.9% benzyl alcohol used to dissolve or dilute medications administered through intravenous, intramuscular, or subcutaneous injection.

The container can be re-entered multiple times by sterile needles for injection because benzyl alcohol stops the growth of a possible contaminating bacteria, making it applicable for multi-dose medications. However, not all drugs are compatible with bacteriostatic water. Sterile water is purified water and does not contain any preservative or antimicrobial agent, making it only applicable for single-dose applications.

Standard criteria for qualifying water as WFI

Pharmacopeias develop standards to ensure that water for injection is pure and safe for its intended application. There are differences in the criteria used by Europe, the USA, and Japan Pharmacopoeias for the production of WFI. Europe requires using distillation processes only while the US and Japan allow membrane and other purification processes.

They all have similarities for some criteria such as for conductivity which should be less than 1.3 mS/cm or total organic carbon (TOC) in organic compounds found in aqueous systems, should not be more than 500 ppb. Endotoxins that are considered as pyrogens that can cause fever to patients should be less than 0.25 EU/mL. In contrast, bacteria or total aerobic microbial count should be less than 10 CFU/ 100mL and pH level between 5.0 to 7.0. These ranges in the criteria are considered safe for applications as water for injection.

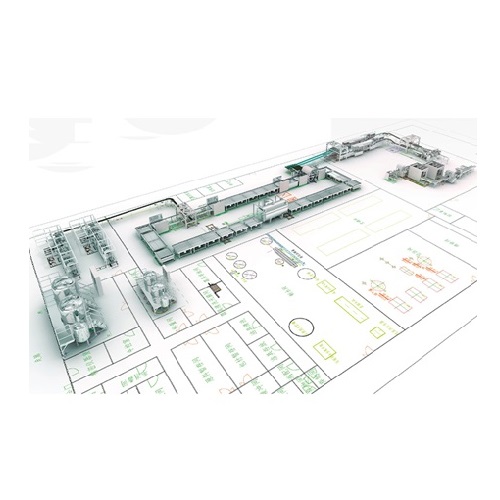

Processing steps involved in water for injection making

Which water for injection technology do you need?

Membrane filtration system for bioburden and water testing

Ensure accurate microbial detection and efficient filtration ...

Purified water generation system for pharma applications

Ensure consistent purity in your therapeutics production with a ...

Purified water storage and distribution for pharmaceuticals

Ensure seamless water quality for critical pharmaceutical pr...

Pure steam generation and distribution system

Ensure reliable sterilization with pure steam that’s free from contami...

Pure steam sample cooler for pharmaceutical industry

Ensure sterile sampling of pure steam while maintaining precise cool...

Wfi cooler

Ensure precise temperature control and contamination-free dispensing for high-value liquid formulations with this a...

Water for injection storage and distribution system

Ensure the integrity and sterility of injectable solutions with this ...

Optical inspection system for large parenteral containers

Ensure the quality and safety of liquid pharmaceutical product...

Superheated water sterilizer for large volume parenterals

When sterilizing large volumes of liquid products, achieving p...

Purified water generation system for pharmaceutical applications

Ensure consistent water purity for critical drug formul...

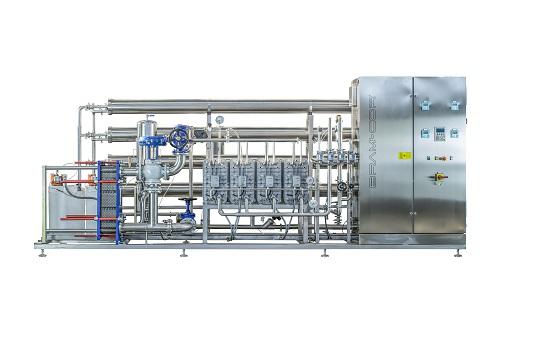

Water for injections generation system

Ensure compliance with strict regulatory standards while providing pyrogen-free wate...

Pharmaceutical water purification system

Ensure compliance with stringent pharmaceutical standards by integrating a reliabl...

Water purification system for Pem electrolyser

Achieve premium water purity essential for hydrogen electrolysers with this...

Ultrapure water system for laboratory applications

Ensure uncompromised water purity for critical applications with a sys...

Centralized water purification system for laboratories

Ensure consistent purity and reliability for your laboratory proce...

Preparation tank isolator for reactor charging

Ensure aseptic conditions for sterility testing and safe handling of sensit...

Full-membrane water for injection (wfi) generation system

Ensure consistent high-quality injections by integrating real-...

Pharmaceutical-grade Pw storage and distribution system

Ensure consistent purity and compliance in your pharmaceutical wa...

Multi-effect water distiller for pharmaceutical and biological applications

Achieve unmatched water purity for sterile...

Pure steam generator for pharmaceutical sterilization

Achieve ultra-pure steam for critical sterilization tasks, ensuring...

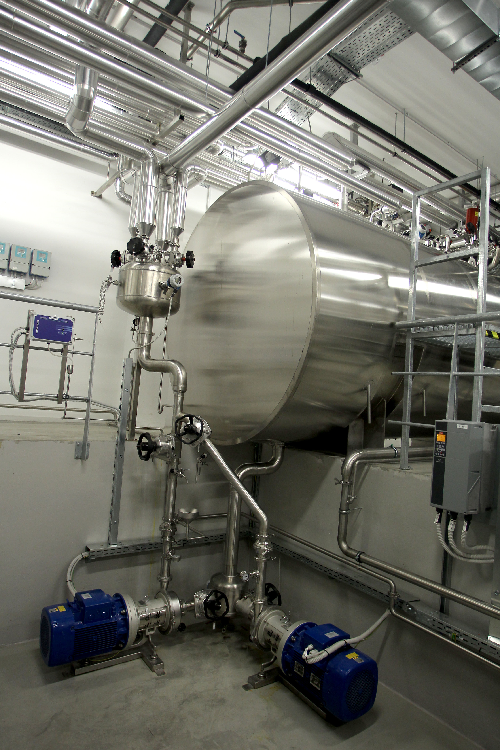

Purified water storage tank for pharmaceutical use

Ensure the integrity of your pharmaceutical formulations with precisio...

Water reuse system for poultry processing

Optimize your poultry processing with a customizable water reuse system designed...

Cip for pharmaceutical process plants

Streamline your cleaning processes with integrated CIP systems to ensure precise and ...

Pharmaceutical isolator system for aseptic production

Ensure aseptic conditions and operator safety with a robust isolati...

Ultra-pure water preparation system for pharmaceutical industry

Ensure your pharmaceutical production line meets stringe...

Hot press distilled water unit for pharmaceutical applications

Ensure superior water purity in pharmaceutical production...

Multi-effect water distillator for pharmaceutical applications

Ensure your production line meets stringent regulatory st...

Pharmaceutical ultra pure water distribution system

Ensure stringent purity standards with a modular water distribution s...

Ultrapure water purification system for laboratories

Achieve consistent high-purity water essential for sensitive laborat...

Superheated water shower sterilizers for parenteral solutions

Optimize sterilization cycles for liquid pharmaceuticals w...

Pure water generation system for pharmaceutical manufacturing

Ensure high-purity water and steam production with precisi...

Multiple-effect water still for pharmaceutical applications

Optimize your pharmaceutical water production with a system ...

Full flow filtration system for bioprocess applications

Ensure sterile filtration of process liquids and aseptic chemical...

Soft bag form-fill-seal system for large volume injection

Streamline your production of intravenous and nutritional flui...

IV bag filling machine

Filling machines for intravenous bags require highly polished surfaces where they contact the bags or ...

Pharmaceutical pure steam generator

Dry, saturated steam can be used to sterilise pharmaceutical manufacturing equipment, a...

Water distillation system

Water used in pharmaceutical processes must meet high standards of regulatory bodies. These includ...

Vapor compression distiller

Water for injections must be of highest achievable quality to eliminate the possibility of conta...

Reverse Osmosis water filtration system

Reverse osmosis uses a partially permeable membrane to remove undesirable molecules...

Pharmaceutical bottle filling machine

Filling machines for pharmaceutical bottles must achieve high production speeds while...

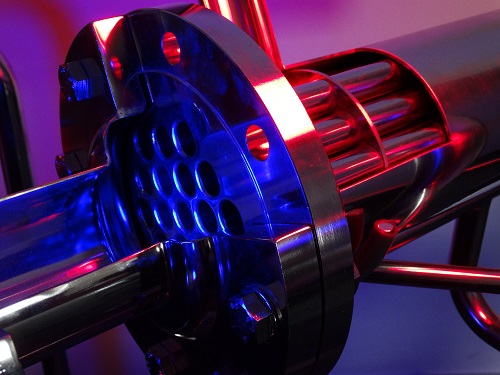

Shell and tube heat exchanger

Heating, cooling and tempering are important processes in the production of many products acro...

Purified water storage tank

Many pharmaceutical and cosmetic production lines require holding vessels for the storage of liq...

Cleaning and sterilization systems

An increasingly vital part of high quality pharmaceutical production is a dedicated Clea...

Purified water systems

Highly Purified water is used in the preparation of medicinal products where bacterial endotoxins need...

Pure steam generator

Pure steam is mainly used in the pharmaceutical industry and in biotechnology for sterilization, water f...

Electrical pure steam generator

Pure steam is defined as the steam which when condensed becomes WFI quality water in accorda...

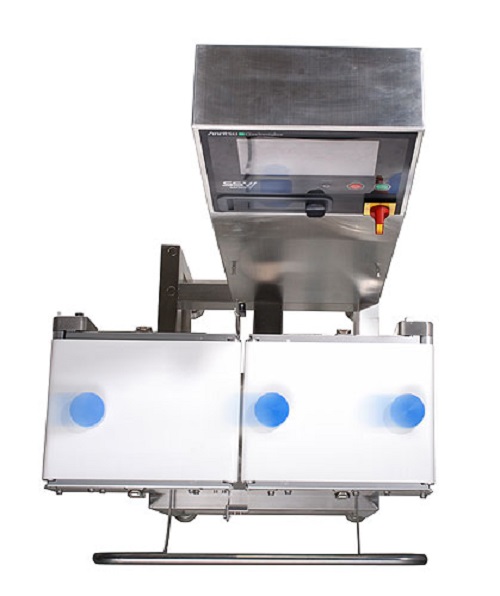

Versatile checkweigher

This Versatile checkweigher is equipped with a highly versatile strain gauge load cell. It is also sui...