Making Decaffeinated Coffee

Find innovative production technology for making decaffeinated coffee and connect directly with world-leading specialists

Some say there is no point in drinking decaffeinated coffee. However, decaffeinated coffee can be an excellent solution for those who love coffee but cannot consume caffeine due to health reasons. The central part of making decaffeinated coffee is the caffeine extraction process, which is conducted while the coffee beans are still green. Then, according to the taste profile you intend, you can roast these decaffeinated beans.

Stories about decaffeinated coffee

Select your decaffeinated coffee process

Tell us about your production challenge

Decaffeination process – three different methods for you!

People often assume that extracting caffeine from coffee beans happens either during the roasting or grinding process – spoiler alert, this is not true. The decaffeination process takes place before the roasting when the beans are still green. There are three typical caffeine extraction processes. Firstly, the most common method, there is the direct chemical solvent method. With this method, the green beans are soaked in water or steamed first. Then, they are rinsed with the chemical solvent which can flush the caffeine away. Ethyl acetate or methylene chloride are commonly used for these chemical solvents.

Secondly, as a sustainable and chemical-free method, there is the Swiss water method. This method uses only water, temperature, and time. First, the beans are rehydrated, so they can easily be extracted. Then they are soaked in heated Green Coffee Extract (“GCE”), a solution containing the water-soluble compounds in coffee. The beans release the caffeine as they are swirled within the GCE for 8-10 hours, then finally carbon filter extracts the caffeine.

Finally, there is the carbon dioxide method. Green beans are put into a stainless steel pressure vessel. With air pressure of up to 1,000 lbs per square inch, carbon dioxide is used in the vessel as a solvent to remove the caffeine. A few hours later, CO2 that contains the caffeine is then removed from the vessel.

Roasting Decaf coffee – different from regular coffee?

Undoubtedly, the caffeine extraction process is an inevitable extra step taken upon the green beans. This means that the decaf beans are processed with one more artificial step compared to the normal coffee beans. This extra processing, which includes rehydration and dehydration, influences the cellular structure of the beans. The beans expand and contract during this processing and become less densely structured. As a result, the moisture left inside of decaf beans is more sensitive to heat.

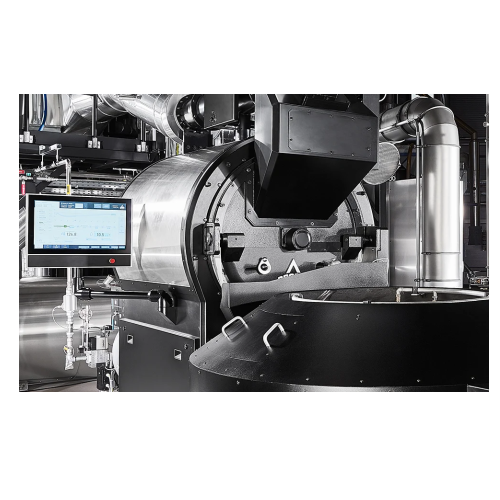

Hence, there are a few points you need to focus on when roasting decaffeinated beans. First, you need to be careful during the drying phase due to the heat-sensitive feature of the beans. Here, applying a lower temperate or lower level of energy than the normal bean would be recommended. Secondly, you should not rely on the color, but you should focus on the smell and time. Decaffeinated beans are darker than normal beans before the roasting, and this makes the evaluation of the roasting process based on color very difficult. Therefore, you should observe the first crack time and development after that instead of looking at their colors.

Processing steps involved in decaffeinated coffee making

Which decaffeinated coffee technology do you need?

P series coffee roasting system

Optimize your roasting precision and flexibility with customizable batch sizes, ideal for ac...

Coffee drum roaster px 120 for industrial use

Optimize your coffee roasting with precise control over batch size and heati...

Automatic shop roaster for small and medium roasteries

Enhance your coffee production with advanced roasting technology d...

Roasted coffee weighing and blending system

Achieve precision and consistency in your coffee blends with cutting-edge weig...

Small batch coffee roaster

Achieve consistent flavors and precision in small-batch coffee roasting with this versatile roast...

Industrial coffee roaster for large-scale operations

Elevate your roasting process with a high-capacity solution designed...

Large-scale coffee roaster for wholesale production

Elevate your coffee roasting with precision and efficiency, ensuring ...

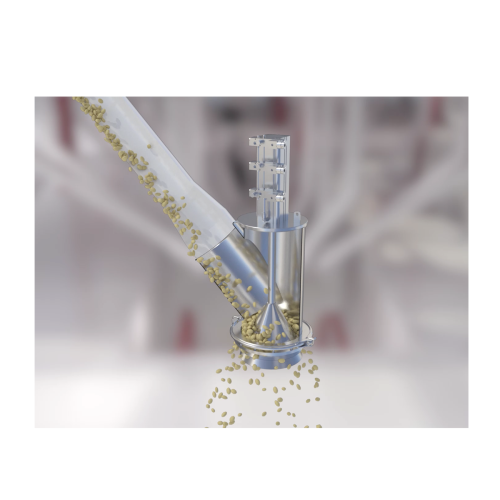

Coffee destoner

Ensure the integrity and quality of your roasted coffee beans by efficiently removing stones and foreign mater...

Modular silo system for coffee bean storage

Optimize your coffee production with a fully customizable modular silo system ...

Industrial coffee roaster for large-scale production

Designed for coffee producers aiming to enhance their roasting capab...

Extraction plant for natural essences and active ingredients

Optimize your extraction processes with a versatile system ...

Thermal process plants for liquid treatment

Achieve precision thermal processing with systems designed to optimize the hea...

Industrial columns and towers for chemical processing

Optimize your chemical production with robust columns and towers, d...

Electrical mini coffee roaster

If you are looking to gain full control of the roasting process, obtain 5 – 6 kg / hou...

Roll mill for coffee beans

When you want flexibility to grin beans for filter coffee to Turkish coffee at particle sizes ran...

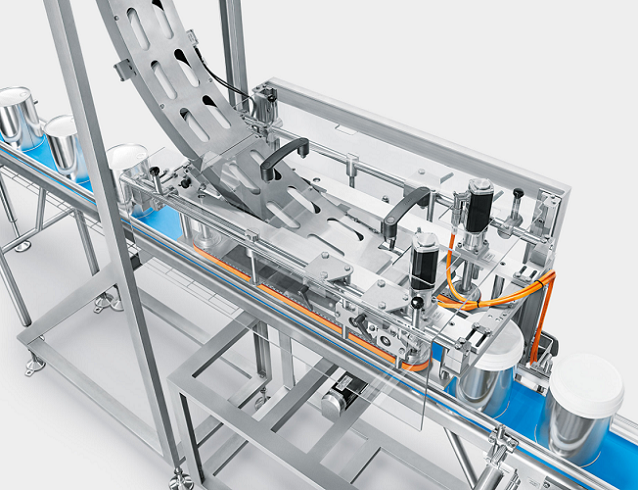

Coffee capsule packing machine

In the secondary packaging sector, being able to handle different type of capsules and tailor...

Seaming machine for infant formula cans

Packaging of food products, but especially those for babies, like infant formula, i...

Leak tester for vacuum packaging

Roasted coffee beans, as well as grounded coffee, rapidly diminish in flavor. The oxyge...

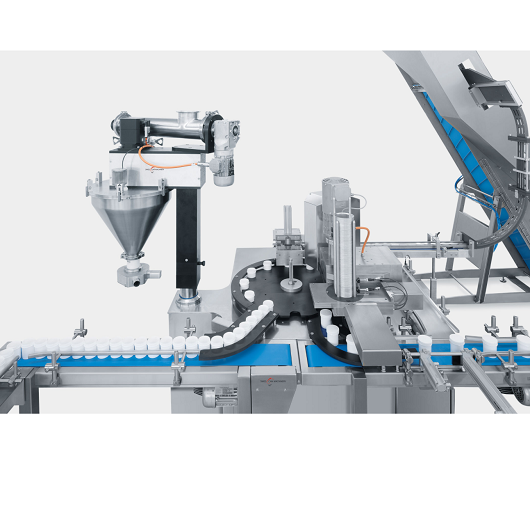

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

Capping machine for plastic lid oatmeal tins

Some products ask for a plastic reusable lid after the can has been sea...

Vibrating screening machine for coffee

Coffee bean separation is one of the important steps during bulk coffee production. ...

Entry level HFFS Machine for flat sachets

Traditional horizontal form fill and seal sachet machines for lower volume lines...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Compact cylindrical roaster for beans, nibs and nuts

Roasting times and temperature can vary depending on the type of pro...

Industrial coffee bean grinder

If you are looking to grind up to 50 kg of fine coffee per our or up to 440kg of medium fine ...

Shop coffee bean grinder

Do you want to grind your beans on-site at your coffee shop, but are you limited for space? Bench-to...

Stone mill for coffee beans

Traditional milling of coffee beans or seeds, with a stationary bedstone and a turning runner st...

Industrial coffee roaster

Roast 120 – 3,000 kgs of coffee beans per hour with the latest industrial technologies integ...

Optical coffee roaster

If you want to see or show all the roasting phases and reactions of the coffee beans, an optical coffe...

Afterburner for coffee roasting

Afterburners for gas-heated coffee roasters in various levels of performance that fit your s...