Making Veterinary Tablets

Find innovative production technology for making veterinary tablets and connect directly with world-leading specialists

There are slight differences between human and animal pharmaceuticals, but that dissimilarity is enough to create new production challenges. Veterinary tablets formulation reflects the diversity of enzymes that different species use to break down substances. Although the methods involved are comparable to human drug manufacturing, equipment and processes need to adapt to a wider dosage variability in veterinary tablets.

Select your veterinary tablets process

Tell us about your production challenge

Keep particle size of API above 10 μm for better flow

The geometric characteristics of the particles in your active pharmaceutical ingredients (API) mixture impact the tableting process. Reducing particle size is a double-edged sword. A smaller surface area favors solubility, but very fine particles become clumpy during manufacturing.

Size distribution of ≥250 μm typically achieves the desired free flow through the line. Ultra-fine API below 10 μm tend are more easily cohesive, resulting in a poor flow.

The ratio of flavorants must not be lower than one-fifth in veterinary tablets formulation.

Some ingredients have a bitter taste or a foul smell that produces an unpalatable aftertaste. The flavor of veterinary tablets is essential in manufacturing chewable dosages.

Flavorants such as sucrose, fructose, and aspartame offer a straightforward solution to offensive taste. But the ratio of the formulation is critical to mitigating intense aromas successfully. The concentration of flavorants needs to reach a minimum of 20% of the formulation.

Reduce processing time with a steam granulation technique

Granulation is a critical step in veterinary tablets formulation. Traditional wet and dry granulation techniques have different benefits depending on the properties of API particles.

Steam granulation is an alternative that combines the strengths of both methods and reduces processing time. A steam generator forms a water film around powder particles producing uniform agglomerates. The energy required to dry the granular matter is significantly lower than in the wet process. However, steam granulation is not suitable for thermolabile ingredients.

Use low-density excipients like iron in bolus formulations

The high ratio of active ingredients in a bolus compared to excipients makes its formulation more challenging. The composition of slow-release boluses, in particular, requires a higher concentration of drugs.

Excipients with a smaller density such as iron, clay, and dicalcium sulfate allow a greater API inclusion. The optimum range density of bolus formulation is 1.5 to 8.0.

Processing steps involved in veterinary tablets making

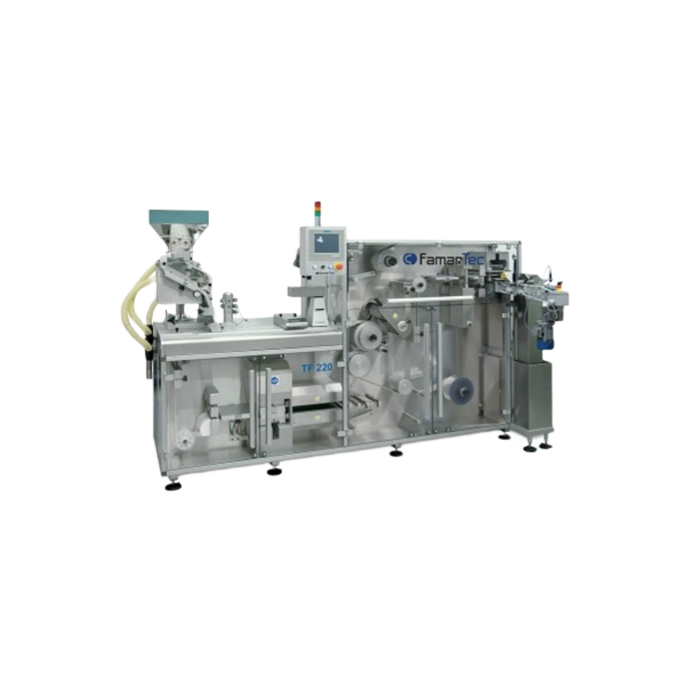

Blister Packaging Equipment

Compaction

Containment isolators

Continuous milling solutions

Dehumidifying

Dosing

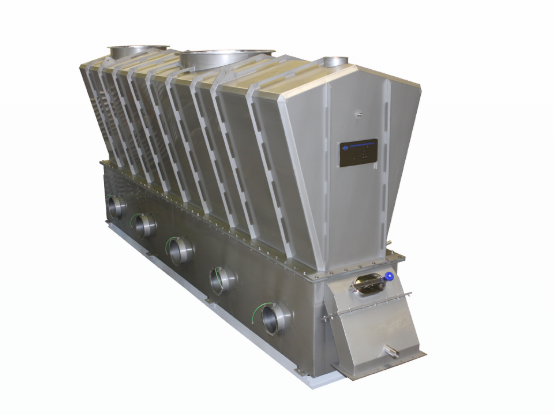

Drying

Fluid bed dryers

Formulation

Granulation

High-shear mixers

Industrial checkweighers

Industrial jet mills

Industrial metal detectors

Inspection

Laboratory mills

Milling

Mixing

Powder presses

Tablet inspection system

Tablet presses

Which veterinary tablets technology do you need?

Laboratory fluid bed system for solvent processing

Optimize your laboratory scale operations with a versatile fluid bed s...

High-output blister packaging system

Maximize blister packaging efficiency with continuous-motion capabilities, ensuring su...

Intermittent motion cartoning machine for blister packs

Optimize your packaging line with a space-efficient cartoning mac...

Small feeder with flexible wall hopper

In many laboratory applications and production processes, smaller quantities of powd...

Single and double layer tablet press

High performance tablet presses that are capable of producing both single and double-l...

Granulation line of mixer and fluid bed dryer

A complete granulation line allows for the mixing and granulation of pharmac...

Single layer tablet press

High performance tablet presses for the modern production environment need to be fast, accurate an...

Rotary tablet press

For pharmaceutical tablet producers looking to reduce waste, costs and increase production volume, a hig...

Premium vacuum conveyor

When you have a need to tailor make your conveyor and still have the high requirement on hygiene, e.g...

Sorption dehumidifier with air-chilled condenser

It is not always possible to duct out the wet air from a dehumidifier ser...

Small portable dehumidifier

Water damaged areas require dehumidification to limit the damage and prepare the area for restor...

Sorption dehumidifier for large temperature differences

Small, humid areas can be difficult to dehumidify in humid ambien...

Sorption dehumidifier for deep drying

Humid ambient conditions such as those in tropical climates make dehumidification mor...

Dehumidifier for difficult wet airflows

Sealed rooms can be challenging to dehumidify with ordinary dehumidifiers. The wet ...

Sorption dehumidifier for overpressured rooms

Small humid spaces, used for processing or storage, often need a simple dehu...

Heat recycling sorption dehumidifier

Facilities that handle large amounts of water can become very humid. High humidity may...

Industrial desiccant dehumidifier

Dehumidification of medium sized manufacturing and processing facilities can be a dauntin...

Large scale desiccant dehumidifier

Moisture sensitive processing and storage facilities need low humidity environments to s...

Customizable dehumidifier

Dehumidification needs can vary significantly from one project to another. Dehumidifiers with a fi...