Making Nasal Spray

Find innovative production technology for making nasal spray and connect directly with world-leading specialists

Smelling is said to be the most underrated sense. But a congested nose quickly reminds us why it is important. Besides the loss of the olfactory function, nasal blockage leads to a dangerous buildup of pathogens in the airways. Nasal spray formulation is the science of mixing drugs and excipients to free your nasal passage. A few spritzes of the right recipe will bring back the scents of life.

Stories about nasal spray

Tell us about your production challenge

Reduce the size of API particles before formulating the nasal spray

Nasal sprays are an effective drug delivery system because the nasal mucosa offers a high permeability. The gastrointestinal route has a low pH environment, so the neutral pH levels of the nasal route cause less dilution.

On the other hand, one shortcoming of the nasal cavity is the relatively limited membrane transport, posing a barrier to drug absorption. To facilitate absorption, mill the ingredients into fine particles with larger surface areas before formulating the drug.

Adjust pH level to between 4.5 and 6.5

With a pH level of around 6.5, the nasal passage is prone to irritation from substances with an acidic level. At the same time, the formula is less permeable if the active pharmaceutical ingredients have lower acidic strength than the nasal pH.

A final pH within the range of 4.5 and 6.5 typically facilitates the permeability of drugs while preventing consumer discomfort. Add pH buffers to control the levels in your nasal spray formulation.

Use gamma radiation to make preservative-free nasal sprays

Multi-dose nasal sprays may develop microbial growth, risking transferring the pathogen to the user. Traditionally, preparations include preservatives like parabens to prevent bacterial attacks. But the long-term use of these chemicals poses risks to the nasal mucosa, causing irritation and other side effects.

The manufacturing process of nasal products must ensure terminal sterilization. In the case of preservative-free formulation, subject the spray pumps to gamma radiation before filling to ensure decontamination.

Consider overheating risks caused by friction during mixing

Nasal spray preparations are formulated with various additives to enhance the drug’s effectiveness. Humectants such as glycerin avert dehydration once the substance is sprayed. Meanwhile, glycols and other medium-chain glycerides maintain the solubility of the formula. Add surfactants or fatty acid salts to boost the penetration of the final product.

Heat is a crucial consideration during formulation, mainly when using thermolabile API. The mechanism of the mixing technology itself may generate friction and raise temperatures that could degrade the formula.

Processing steps involved in nasal spray making

Which nasal spray technology do you need?

Tube filling station for plastic, laminate, and aluminum tubes

Efficiently seal and fill various tube materials, ensurin...

Labelling system for blow fill seal (bfs) strips

Ensure precise labeling and traceability for your blow fill seal containe...

Rotary filling and closing system for pharmaceutical bottles

Optimize your large-batch liquid production with a high-spe...

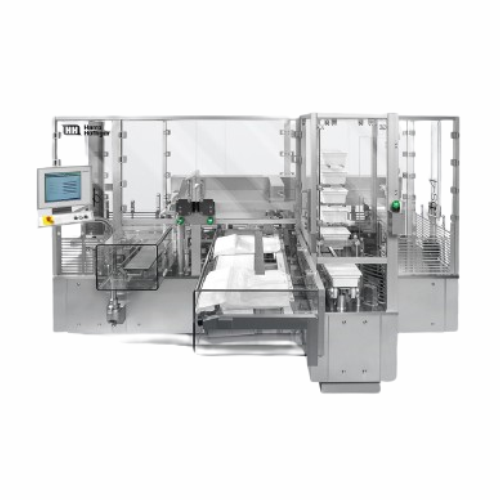

Double bagging solution for sealed tubs

Achieve sterile packaging for medical and pharmaceutical products with a compact, e...

Liquid filling system for medical and pharmaceutical products

Enhance your production capabilities with high-speed liqui...

Liquid dosing and assembly platform for pharmaceutical products

Optimize your production line with a seamless solution f...

Aseptic filling solutions for Rtu vials, cartridges, and syringes

Optimize your aseptic filling processes with a system...

Nasal spray and eye drop filling solutions

Enhance the precision and flexibility of your liquid filling operations with ou...

Benchtop filling solutions for small batch liquid medicine

Streamline your small batch liquid medicine production with p...

Filling system for consumer healthcare products

For small to medium productions needing versatile filling and sealing, thi...

Filling solution for consumer healthcare products

Navigate complex liquid product formulations with a versatile filling s...

Filling solution for non-injectable pharmaceutical products

Streamline your pharmaceutical production with a versatile s...

Mobile isolator for aseptic environment transfer

Ensure aseptic conditions and seamless material transfer with this mobile...

Intermittent stick pack packaging system for pharma products

Achieve precise dosage and packaging of pharmaceutical and ...

Intermittent stick pack system for pharmaceuticals

Effortlessly streamline your packaging process with a high-speed, mult...

Rotary continuous motion bottle cleaning solution

Ensure pristine product integrity by effectively eliminating particles ...

Full-membrane water for injection (wfi) generation system

Ensure consistent high-quality injections by integrating real-...

Superheated water sterilization autoclave for pharmaceutical applications

Ensure precise sterilization of sensitive li...

Washing machine for pharmaceutical stoppers and caps

Streamline your aseptic processing with precise washing, sterilizati...

Vertical ultrasonic washing for pharmaceutical containers

Ensure immaculate cleanliness and sterilization of pharmaceuti...

Complex preparation system for industrial microsphere production

Achieve precise particle size and uniform drug encapsul...

X-ray inspection for pharmaceutical vials

Ensure product purity by detecting contaminants in pharmaceutical vials with adv...

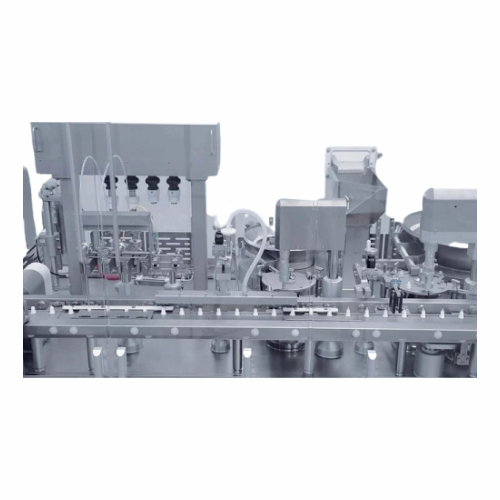

Pharmaceutical drops and sprays filling system

Streamline your liquid formulation process with precision filling and seali...

Semi-automatic capping machine for aluminium screw caps

Ensure consistent cap application across diverse container format...

Nasal spray filling solution

For precise nasal spray production, achieve seamless filling, stoppering, and capping to ensure...

Robotic syringe filling system for sterile pharmaceutical production

For high-precision liquid dosing in sterile enviro...

Tapped density tester for pharmaceutical powders

Ensure precise quality control in pharmaceuticals by accurately measuring...

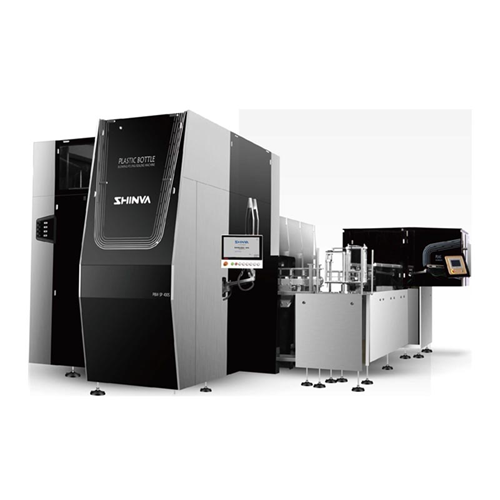

Reciprocating plastic bottle blow-fill-seal system

Achieve seamless integration of bottle forming, filling, and sealing w...

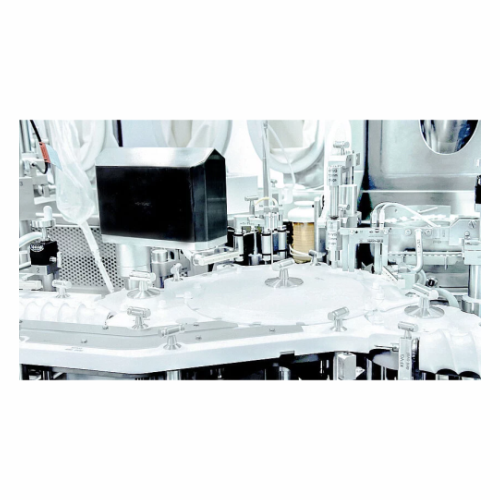

Rotary transfer system for pharmaceutical product filling

Ensure precise and hygienic filling of diverse pharmaceutical ...

Agitator bead mill for API

To achieve precisely defined API properties and safe and reproducible production, rigorous implem...

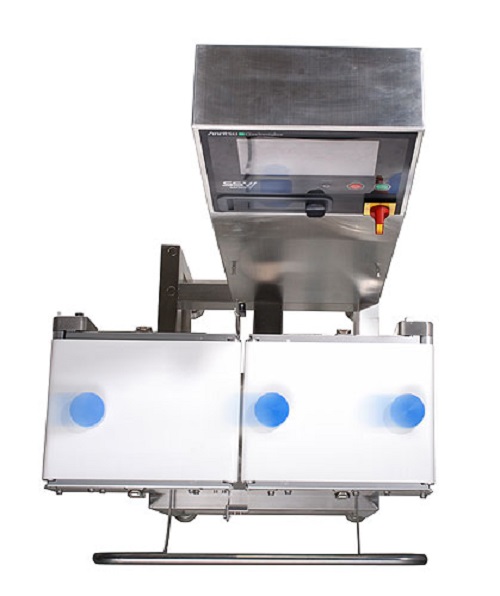

Small bottle checkweigher

Any small-diameter bottle, containing prescription medication or cosmetic applications, can be pro...

Versatile checkweigher

This Versatile checkweigher is equipped with a highly versatile strain gauge load cell. It is also sui...