Making Truffle Cream

Find innovative production technology for making truffle cream and connect directly with world-leading specialists

In 2009, billionaire Stanley Ho made the winning bid for a giant white truffle weighing 3.3 pounds during an auction. Price: $330,000. Looking at the price, there's no need to explain why truffles are called the diamonds of the kitchen. After harvesting, they are selected to be sold fresh or processed to make truffle products such as truffle cream. Truffle processing involves cleaning, cutting, grinding, cooking, packaging, and sterilizing.

Select your truffle cream process

Tell us about your production challenge

Truffle processing – selection and cleaning of truffles

There are almost one hundred varieties of truffles in nature, but only nine are considered edible and can be on the market. After harvesting, the truffles are manually selected according to their shape and aroma. The best ones are sold to be eaten fresh or frozen for export. To be categorized as the best ones, apart from the tuber’s shape and size, the truffle must be hard to the touch and above all, it has to smell a little earthy.

The others instead are used for the processing of various preserved products such as truffle cream. Truffle processing to make truffle cream begins after sorting when producers brush and wash the truffles to remove the excess soil in accordance with good practice guidance.

How to make truffle cream – cooking, filling, and sterilization

To make the truffle cream, oddly enough from what the name says, truffles are not the only ingredient, but a small percentage of them. They are combined with porcini mushrooms that have been chopped into small pieces and cooked beforehand. When mushrooms are ready, producers mix and blend them with truffles until the mixture reaches the desired creamy consistency. Apart from truffles and mushroom, ingredients such as vegetable oil, salt, and aroma vary depending on the customer’s recipe.

When the mixture is ready, a volumetric dosing machine fills glass jars with the truffle cream, which a capping machine then seals immediately afterward. To extend the product shelf life and to remove the presence of pathogenic microorganisms, producers place truffle cream jars in an autoclave for sterilization. Thanks to the applied heat, you can eliminate the biological agents that compromise food safety.

How climate change is affecting the survival of truffles

It’s been a few years that truffle hunters and producers of truffle products have been worrying about truffle production. Since the 19th century, truffle production in France has dropped from 1000 tons per season to only 30 tons per season. That’s why truffles are 70% water and need rain to grow; so their production is closely related to how much rain falls during the summer before the harvest. And unfortunately, over the last 40 years, summer rains have been fewer and fewer, and summers have been drier and drier.

To counteract the long-term effect of climate change on truffles, experts seek to encourage land preservation in order to safeguard the symbiosis (mycorrhiza) between the truffle and the host tree. Truffles are fruiting bodies, meaning that they need trees to grow. Unlike apples or other fruits, they grow wild underground near the trees. Truffles take sugar and water out of the trees and in return they help the host tree to reach nutrients of the soil it cannot reach by itself.

In addition to preserving the land, farmers are trying to farm truffles, but the process is not so simple and there are some varieties that cannot be cultivated at all, like Italian white. When planting a tree, you need to make sure it has the right soil conditions (well-drained soil and pH between 7.5 and 8.3) and then inoculate it with the truffle fungus. The important thing is to keep the tree healthy by watering it constantly. But even so, it may take years before you get a good harvest and there’s no guarantee that the result will be worth the effort. “Using state-of-the-art climate model projections, we predict that a significant decline of 78-100% in southern European truffle production is likely to occur between 2071 and 2100.”

Processing steps involved in truffle cream making

Which truffle cream technology do you need?

Inline chocolate filter for large particle removal

Ensure the purity and consistency of your chocolate products by effici...

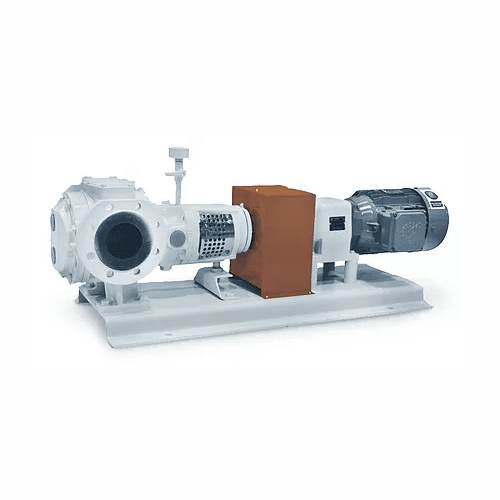

Chocolate pump for confectionery production

Effortlessly pump and convey a range of chocolate-based products with precisio...

Advanced dough mixing solution with removable bowl

Efficiently blending and kneading diverse doughs, this mixer enhances ...

Nougat tempering system for consistent viscosity

Achieve consistent quality and precision in praline centers and nougat ba...

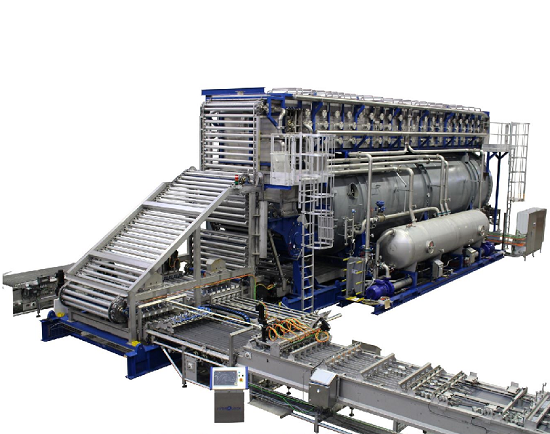

Autoclave Steam Sterilizer Machine for Ready Meals

When selecting a sterilizer for your ready meals, finding the right si...

Multifunction case packer for bottles and jars

New ways of packaging products are popping up all the time on the market. T...

Wrap-around case packer for cans or bottles

When it comes to beer packaging, most of the manufacturers use plain box carto...

Centrifugal mixer for batters and creams

Batters, creams and other delicate sauces and emulsions take time to mix, reducing...

Continuous sterilizer for tin cans and jars

A concern in the coffee industry is maintaining the freshness, taste, and qual...

Linear machine for wraparound label

Wraparound labels allow you to offer detailed information using a small space or fit ex...

Automatic filling machine for sauce

Traditional sauce filling units can struggle to maintain a high quality of output in ca...

Pre-made cup filler for salad dressings

Pre-made cup fillers are mostly used by food companies to assist in the mass produc...

Universal Mixer and Cooker for Sauces

Sauce cookers and mixing machines have traditionally been designed to suit one proces...

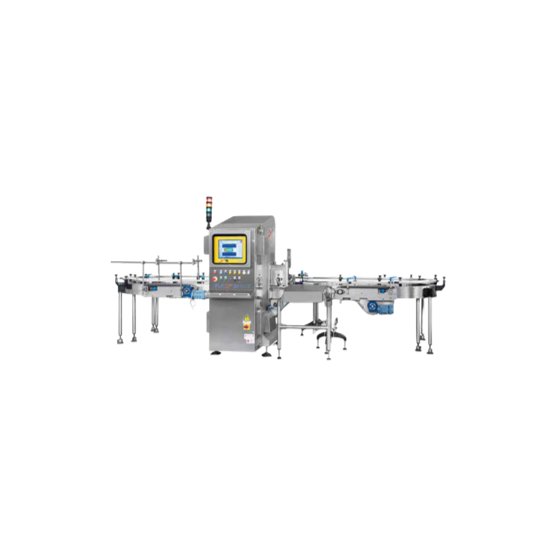

X-ray inspection machine for jars

Inspection of glass jars and bottles for foreign object contamination is a vital part of ...

Autoclave for canned food

Sealing and cooking products in cans, pouches or other containers is a very popular method of pres...

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

Industrial vegetable cutter

Retaining freshness in cut vegetables, as well as retaining vitamins and nutrients, is a top pri...

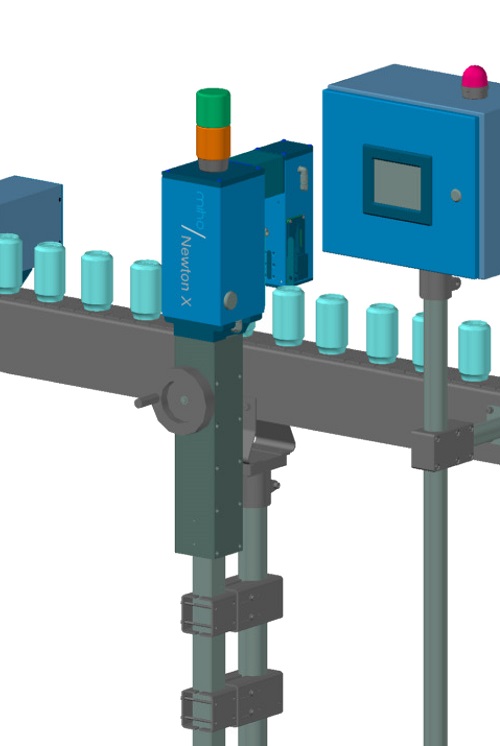

X-ray fill level controller

For containers that are difficult to see through, such as cans or cartons lined with aluminium, ...

Optical fill level controller

Accurate fill level inspection for transparent, opaque and foaming liquids, that makes sure th...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...