Making Truffle Balls

Find innovative production technology for making truffle balls and connect directly with world-leading specialists

The beginnings of chocolate truffles are a bit like the treat itself, misshapen and dusty. But it is a sign of success when multiple sources claim credit for a recipe. Truffle balls manufacturing equipment today forms can truffles into perfect spheres, but the original deliciousness is left unblemished.

Select your truffle balls process

Tell us about your production challenge

Use a vacuum mixer to prevent air bubbles in the ganache

The heart of truffle balls is the ganache. Blend two parts of chocolate with one part of cream to produce a firm consistency that can be rolled into a ball. The oils in the chocolate fats and the water content in the cream form an emulsion as the blend is mixed.

But air bubbles could lead this oil-in-water emulsion to come apart. Mix the blend under a vacuum to lock out any air while the fat and water particles disperse in the sugar syrup.

Add definition with specialized truffle balls manufacturing equipment

The classic chocolate truffle was hand-rolled into a ball, but the shape of the final product is only limited by the creativity of manufacturers. Forming machines are central equipment for truffle balls manufacturing.

To make rectangular shapes, let the firm ganache set in a vessel and trim it down using a strand cutter or guillotine for confectionery products. For 3D shapes, deposit the mixed ganache in a molding machine and allow it to cool.

Set the final heating to 30°C when tempering milk chocolate

The ganache heart of chocolate truffles is enclosed in a shell of chocolate. To achieve an ingredient that is both workable and smooth in texture, temper your chocolate before dipping the ganache center.

A tempering machine raises the temperature of the chocolate to 46°C before cooling it to around 26°C. A second process then reheats it to 30°C. If you’re using white or dark chocolate, the reheating goes to 29°C and 31°C, respectively. Tempering reduces the crystals to their smallest size and distributes them evenly throughout the chocolate.

Coat the truffle balls before the chocolate shell cools down

Truffle balls are universally identified by their dusty exterior. The treats are individually enrobed in a layer of cocoa powder that contrasts with the filling and gives them their distinctive look.

Enrobing machines, however, can work with multiple ingredients. From nuts to nonpareils to chili powder, chocolate truffles can be paired with all sorts of layering materials. Place the balls in the coating equipment before the tempered chocolate shell cools down completely to retain its adhesiveness.

Processing steps involved in truffle balls making

Which truffle balls technology do you need?

Chocolate tempering system for mould filling and vibrating

Ensure a flawless finish for chocolates and confections with ...

Industrial chocolate flaking system

Achieve precise chocolate flake dimensions effortlessly, enhancing product textures and...

Laboratory refiner/conche for chocolate processing

For chocolate producers seeking precise control over texture and flavo...

Commercial chocolate refiner/conche

Elevate your chocolate production with a versatile 5-in-1 solution, integrating cocoa m...

Chocolate depositor for small to medium production

Optimize your confectionery production with a versatile depositor that...

Chocolate products aligner for chocoform extruder

Enhance your chocolate production line efficiency with a precision alig...

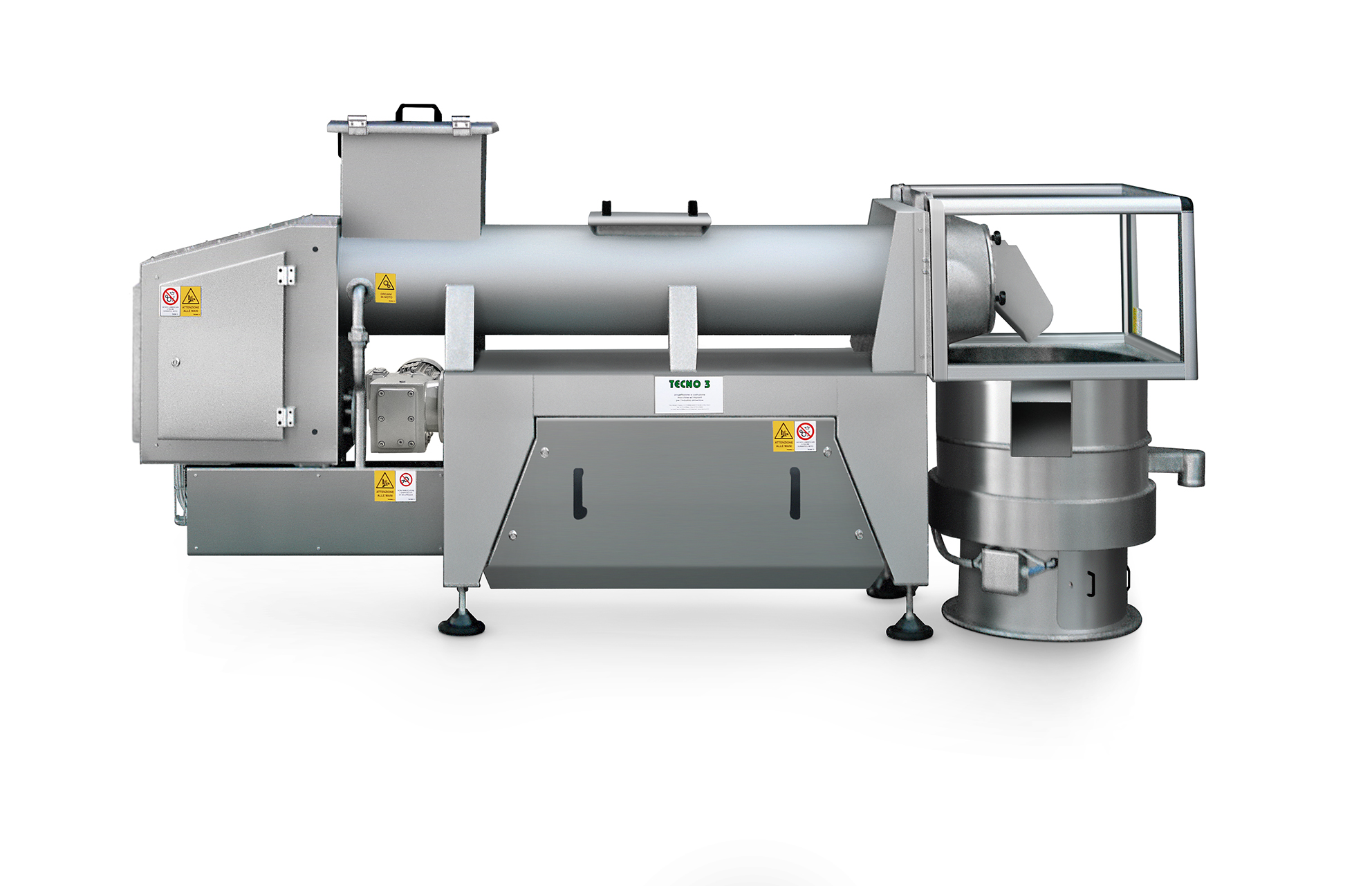

Mixer for production of chocolate with inclusions

Using the same mixing equipment for different recipes in chocolate manu...

Refining plant for chocolate

Achieving a balanced, velvety mouthfeel in chocolate is challenging. Larger particles in chocol...

Industrial melter for chocolate rework

Wastage or out-of-specification products are not uncommon in the chocolate manufactu...

High-speed chocolate block melt machine

If you produce chocolate using larger blocks instead of cocoa beans, chocolate melt...

High capacity tempering machine

Prepare chocolate mixes for application to your product as coatings. Enhance the attractiven...

Chocolate truffle rolling machine

For automatic truffle ball enrobing.

Compact enrober

Cost-effective enrober for medium productions.