Equipment And Machinery For Making Shrimp Crackers

Find innovative production technology for making shrimp crackers and connect directly with world-leading specialists

Shrimp or prawn crackers are savory snacks common in Asian countries. Believed to have its origins in West Malaysia, this snack is part of daily common cuisines or as a midday snack. Prawn cracker manufacturing has a strong demand, with Indonesia exporting 1.648 million kg as of May 2019.

Select your shrimp crackers process

Tell us about your production challenge

Simplifying shrimp slicing in prawn cracker manufacturing

Shrimp slicing is a critical process in prawn cracker manufacturing. How you slice your crackers affects oil absorption and crispiness of the final product. Thicker slices absorb lesser oil compared to thin slices since they have a higher moisture content. Thinly sliced crackers have a faster cooking time.

During prawn cracker manufacturing, the starch you use for dough making affects slicing, specifically on its elasticity. For example, using tapioca starch, although gluten-free, makes your shrimp cracker dough more elastic and difficult to slice. As a remedy, you may add reducing agents such as L-cysteine and sodium bisulfite to soften it and make it easier to slice.

With this, cutting machines should be appropriate to the properties of your product. You must carefully consider the dough cutting speed. Setting a higher speed results to thicker shrimp cracker slices while the reverse is true at lower speed. You may lubricate the blades to better aid the slicing process of the shrimp cracker dough.

Frying in and fatting out your shrimp crackers

Cooking your shrimp crackers requires that they are deep fried for 10 to 15 seconds to ensure crispiness while reducing oil absorption. You may do this using either a deep fryer (for non-continuous processes) or conveyor fryers (for continuous processes). You can also substitute the frying oil with healthier alternatives, such as sunflower, canola, peanut, and avocado, to increase your shrimp crackers’ nutritive value. However, you should be careful of the produced free fatty acid (FFA) when using these. Normal FFA should only range from 0.5 – 0.8% during frying; excess levels would result to the development of rancidity and off-flavors on your crackers.

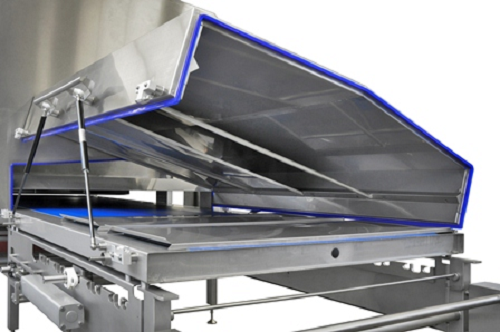

After frying, de-fat the shrimp crackers using de-fatting belts and air knives. Removing excess oil from frying provides additional value to your shrimp crackers while promoting crispiness and extending their shelf-life. If not done, this can make your crackers soggy while also making them prone to rancidity and to develop off-flavors. De-fatting belts work by shaking your freshly cooked shrimp crackers, causing excess oil to be shaken off. On the other hand, air knives apply pressurized air to forcibly remove adsorbed oil on the surface of your crackers.

Not a healthier alternative (but it could be)

Contrary to belief, shrimp crackers are not healthy snack alternatives. A study in Ireland has shown that a serving of shrimp crackers from the usual Chinese takeout contains 608 calories, a third of an adults’ daily calorie intake. For comparison, a serving of corn chips and potato chips contain 160 calories each.

It is then important to consider healthier ingredients and establish value-adding processes. You may consider using alternative oils, such as coconut and olive oil, or using de-fatters and air knives to rid of excess oil, producing healthier shrimp crackers.

Processing steps involved in shrimp crackers making

Which shrimp crackers technology do you need?

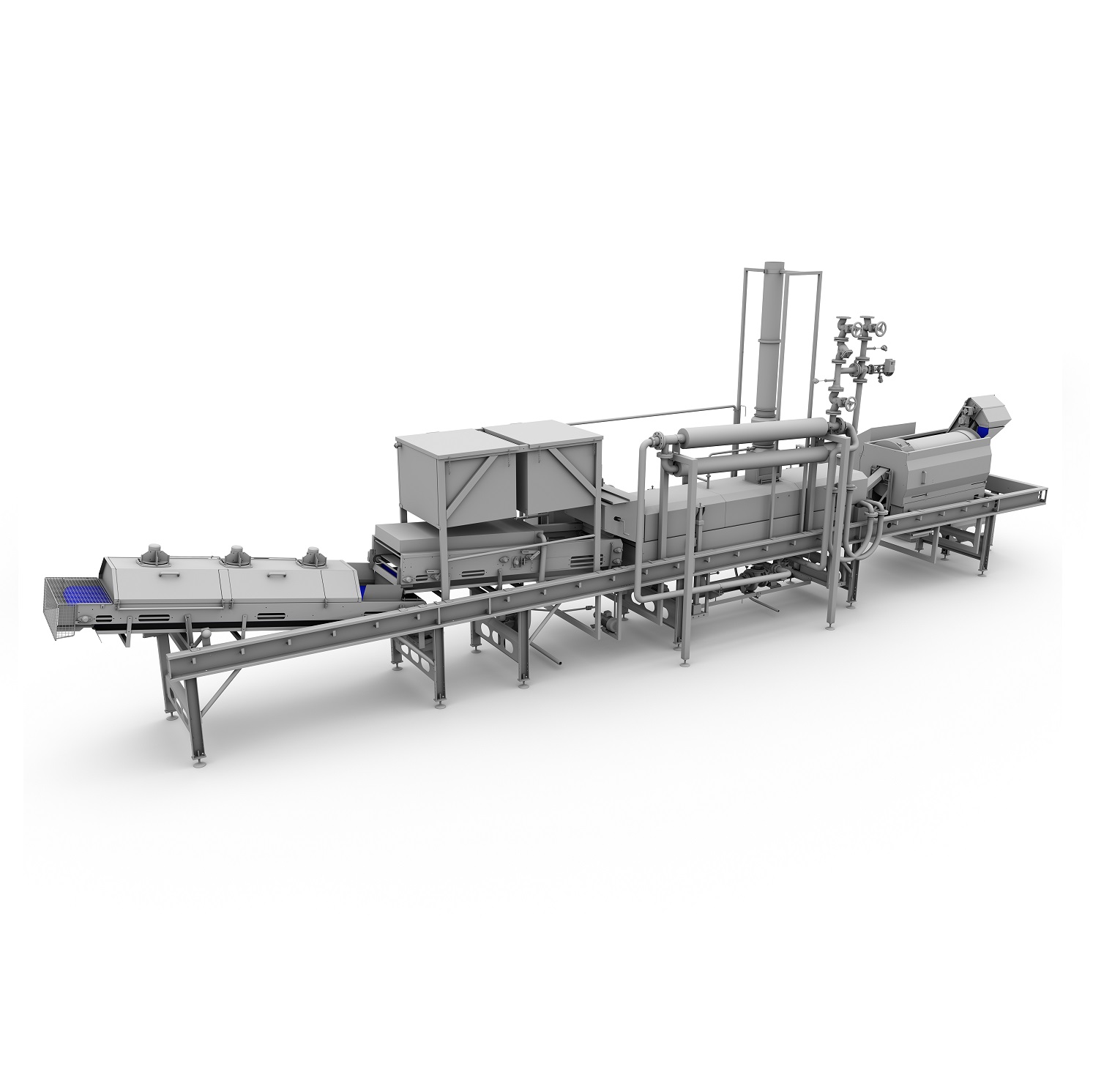

Pellet snacks frying line

Pellet-style snacks represent a broad food sector category. They are consumed worldwide and vary a...

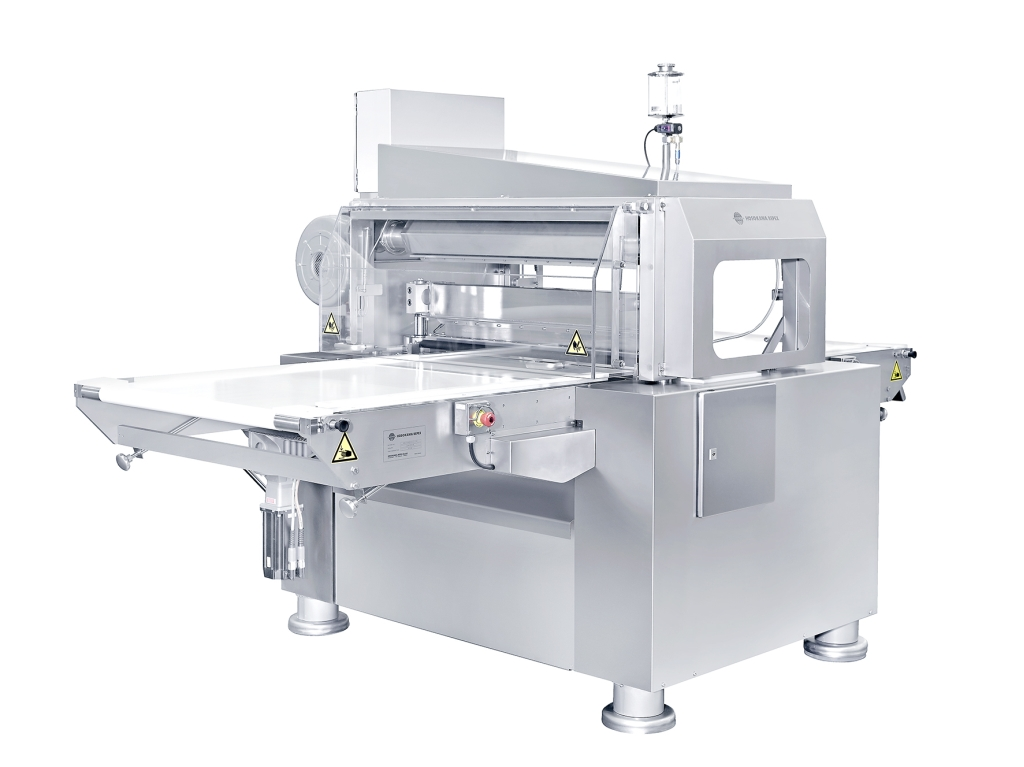

Guillotine cutter for confectionery

Confectionery products such as marshmallows, licorice candies, and fudges come out of e...

Industrial guillotine machine for extruded foods

Textured vegetable proteins made from soy, wheat, and oats are extruded i...

High capacity freezer for food

Freezing is one of the most important industrial methods for the long-term preservation of fo...

Robotic case packing machine for snack bags

Automated packing with robotic suction arms can quickly pickup packaged produc...

Cake ultrasonic cutter

Some cake items you may wish to cut can feature substantial amounts of cream. But that cream could sme...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

Puffed snack making machine

In the snack food industry, most products are often fried or extruded with a cooker, before bein...

Hygienic and fully-welded spiral freezer for food

Food freezers are often the last step in the food production chain. The...

High capacity spiral cooler for food

Cooling baked goods and food products can be problematic for sliced baked goods. A cru...

Strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other final product sha...

High-speed strand cutting machine

Cut continuous strands and slabs of your ingredient mix into bars, strips, and other fina...

Hygienic chocolate cooling tunnel

Quickly cool your product after cooking in preparation for further processing. This is a ...

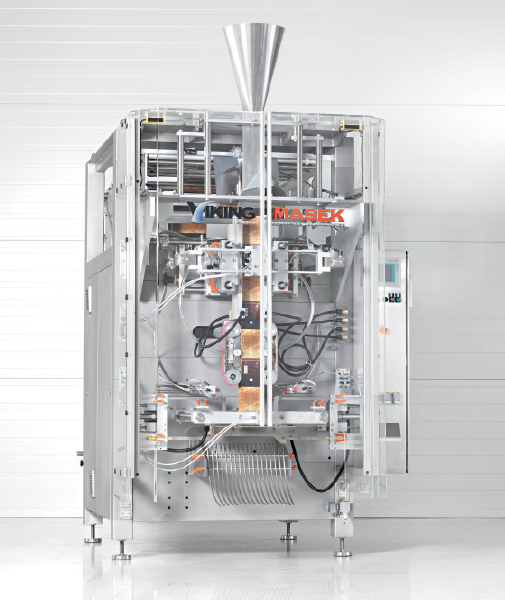

Bagger with servo driven jaw actuation

If you want to accommodate multiple bag designs and dimensions with fast speed and a...