Making Tea Tree Oil

Find innovative production technology for making tea tree oil and connect directly with world-leading specialists

Tea tree oil, also known as melaleuca oil, is an essential oil with immune system stimulants produced mainly in Australia. The tea tree oil manufacturing process starts from the leaves of Melaleuca alternifolia. In terms of market value, the one for tea tree oil was valued at 38.8 million USD last 2017 and is projected to increase to 59.5 million USD by 2025.

Select your tea tree oil process

Tell us about your production challenge

Extract, distillate, purify: the tea tree oil manufacturing process

Tea tree oil production involves steam distillation, condensation, separation, and collection of the essential oil. It starts with the use of a distillation still which allows the Melaleuca alternifolia tea tree leaves to be steamed at approximately 100 °C for 2 hours. The generated steam then passes through a condenser with temperatures of 35 to 55 °C, forming an oil-water mixture. It then goes through a separator wherein it’s possible to separate the essential oil from the water. To further improve the quality of the product, you may subject the tea tree oil to a refinement process, to increase its commercial value. For that, you use a vacuum distillation column.

After you extract and distillate the oil, you normally refine it to increase the amount of terpinen-4-ol and decrease 1,8-cineole. After steam distillation, your tea tree oil should contain around 45 to 50% of terpinen-4-ol; refining the essential oil increases this to around 75-90%. As a by-product of refining, you also get 1,8-cineole, a major component of eucalyptus, known for relieving mucous build-up in the respiratory tract.

The essence of tea tree oil in aromatherapy and health care

The Melaleuca alternifolia tea tee has been used therapeutically for many centuries in Australia, where it is also approved for use in aromatherapy. This essential oil is a known antimicrobial and antifungal agent, able to eliminate bacteria and fungi. As such, your tea tree oil can be used topically for acne treatment, facilitate wound recovery, and reduce inflammations. In addition, tea tee oil can be infused with other cosmetic products, such as soap, shampoo, face oil, or even other oils such as argan oil.

However, the dosage must be controlled as tea tree oil can be irritating at high doses. Furthermore, some people exhibit an allergic reaction to it. There have been reports saying that the use of tea tree oil causes endocrine disruption in children. However, medical reviews have shown that there is insufficient evidence to support this claim.

Tea tree oil essential quality indicators

The standard ISO 4730:2017 describes the chemical composition of Melaluca essential oils, which may include M. dissitiflora, M. linariifolia, and M. uncinata. However, studies have shown that commercial tea tree oil is derived from the foliage and terminal branchlets of M. alternifolia. This species is an extremely fast-growing tree, providing a renewable and sustainable source of the oil. To further maintain the value of your tea tree oil, take extra care during storage and shipping after packing your final product. The essential oil must not be exposed to ambient air, light, humidity, and high temperatures. These environmental factors can trigger oxidation of your oil, increasing its potency to cause allergic reactions to your consumers when applied topically.

How sustainable can the tea tree oil industry be

The manufacture of tea tree oil and other essential oils, in general, are far from sustainable. With percent recoveries ranging from 0.006% to 3%, a lot of raw material is needed to meet the market’s demand. In the case of tea tree oil, the additional factor of the Melaleuca trees being native to Australia poses a problem due to possible overharvesting. To promote sustainability, the use of vacuum distillers would enable you to produce a higher quality and more concentrated tea tree oil, which is potent even in small doses. You may also opt to get certifications that assure customers of ethical farming and sourcing practices of your business.

Processing steps involved in tea tree oil making

Which tea tree oil technology do you need?

Decarboxylation package for botanical extraction

Optimize decarboxylation and reaction processes with precise temperature ...

Benchtop peristaltic dispenser

When you fill vials and ampoules, high standards of hygiene are required to avoid the risk of...

Benchtop piston filling equipment for vials in trays

Vials are difficult to fill individually through manual methods due ...

Semi-automatic vial crimper

In a small production line, crimping vials manually can cause fatigue to your operator due to mu...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

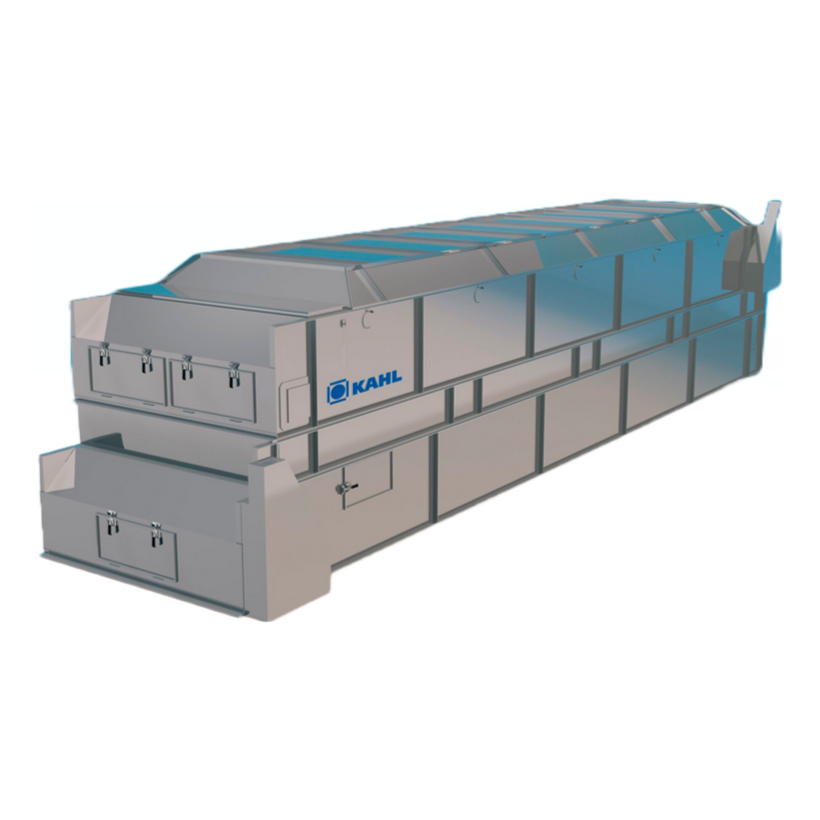

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

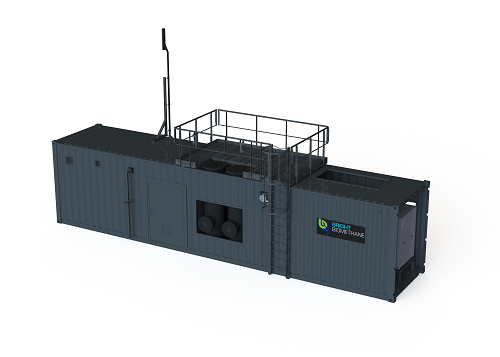

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

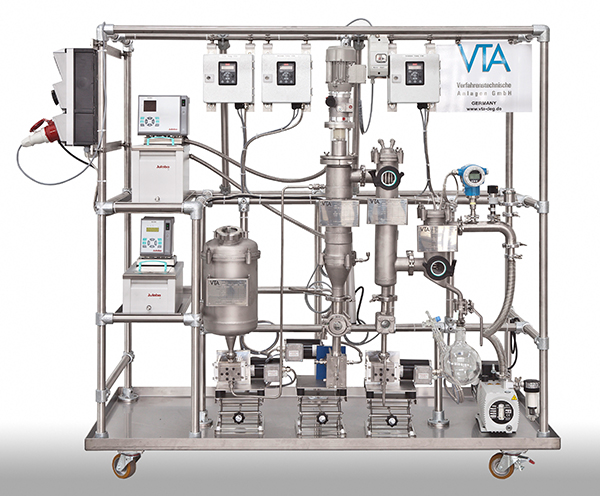

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

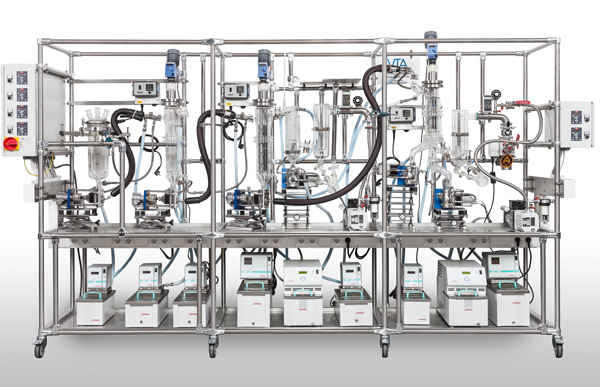

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory wiped film distiller

Reach reliable conclusions testing the distillation of high-boiling or highly viscous materi...

Laboratory short path distiller

Get to reliable conclusions for the separation of high-boiling and heat-sensitive products u...