Making Dried Meat

Find innovative production technology for making dried meat and connect directly with world-leading specialists

Drying meat was the prevalent method of conserving meat cuts when food could not be chilled. But dried meat products developed into delicacies and remained a culinary mainstay long after the functional need for preservation was answered with refrigeration. The ancient techniques have been replaced by dried meat processing equipment, but the time-honored recipes remain unchanged.

Stories about dried meat

Select your dried meat process

Tell us about your production challenge

Dried meat processing equipment for thawing raw products

Slaughtered animals are chilled to ensure decontamination and delivered frozen. Before the raw material can be cut into strips, the temperature has to be brought back up. Thawing is achieved at 0°C, but mechanical cutting can handle the process at the tempering phase (around -5°C).

Thawing systems apply either surface conduction or electrical heat transfer. The former includes immersion in liquid media and vacuum heat technology. Electric equipment such as microwave and infrared technology are faster and do not alter the appearance of the material.

Soak meat cuts in a saline solution to keep the surfaces moist

A fundamental characteristic of meat drying is trimming the parts into equal strips to ensure homogenous evaporation and aging. But the moisture in the muscle structure must be released gradually, starting with the innermost layer. If the surface layer dries up before the lower tiers, it blocks water discharge, providing a welcoming environment for microorganisms.

Immersing the strips in a 14% salt solution before drying forms a hygroscopic layer that keeps the surface moist. Additionally, the salt protects the meat from pathogen growth.

Salt treatment tenderizes cured meats

Salt is the star ingredient in cured meats like hams, salami, and liver sausages. The meat strips are tumbled with the mineral before being set for drying.

Besides adding flavor, salt lowers the water activity values to fend off microbial attacks. Salting also leads proteins in the muscle tissue to swell and dissolve, producing a tender texture in the final product.

Increase the surface area of dried meat snacks to reduce moisture further

Dried meat processed for snack foods such as beef jerky or biltong has a lower humidity level than cured meats. The water activity value is below 0.80, while moisture content ranges from 22% to 24%.

The meat strips are further sliced down to increase the surface area and release more moisture during drying. Some methods, like gueddid and bak kwa, call for overnight marination before they are finished by smoking or cooking.

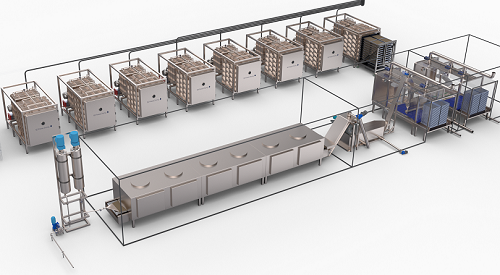

Processing steps involved in dried meat making

Which dried meat technology do you need?

Industrial fruit drying cabinet

Efficiently transform fresh produce into long-lasting, nutrient-dense snacks with precise dr...

Continuous belt dryer for industrial production

For operations requiring precise moisture control, this continuous belt dr...

Stir fryer for industrial food production

Streamline your culinary operations with this innovative stir fryer, designed to...

Compact food dehydrator with Bpa-free trays

Achieve precise dehydration with compact, kitchen-friendly equipment, perfect ...

Compact food dehydrator for fruits and meats

Achieve precise dehydration of fruits, vegetables, and meats with a compact s...

Food dehydrator with stainless steel trays

Achieve optimal dehydration with precise temperature control and efficient dual...

Bone bandsaw for frozen meat and fish

Optimize your meat and fish processing with a bone bandsaw designed for precision cut...

Mesh belt food dryer

Achieve uniform and efficient drying of diverse materials with the mesh belt food dryer, designed to max...

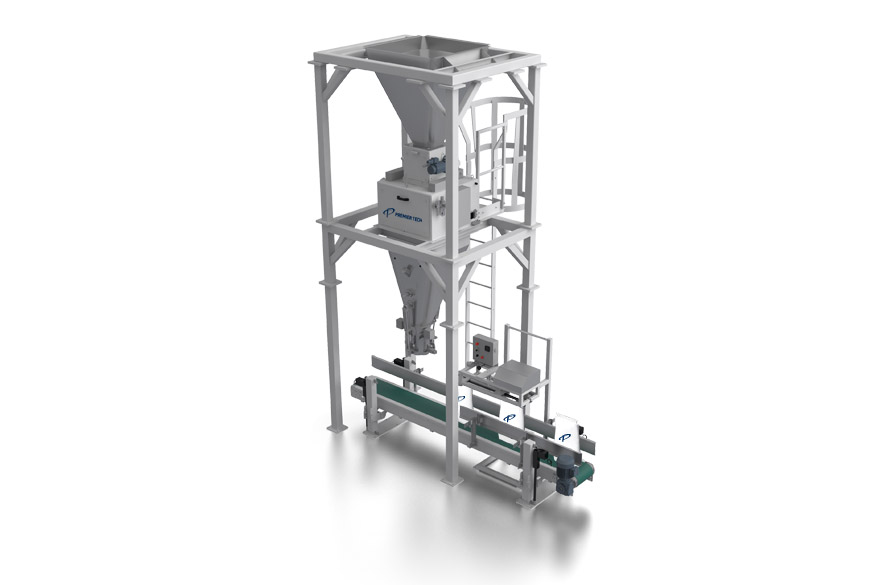

Manual bagger with net weigher

If you are looking for a weigher that is manually controlled for bagging, here it is. It has ...

Box erector and bag inserter

If you are looking to improve your throughput and eliminate labor associated with manual box er...

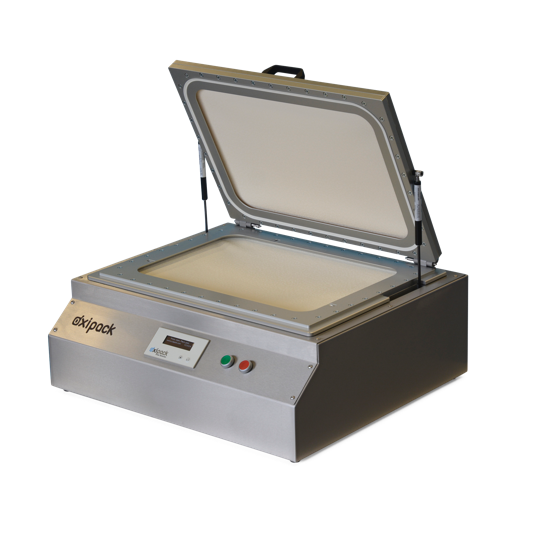

Leak tester for pouches and MAP packaging

Nuts are packed with unsaturated fatty acids, which means they are prone to oxid...

High speed carton closing machine

Choosing a carton closing machine becomes a significant consideration when the closing of...

Washing cabinet for trolleys

Food manufacturing facilities, bakeries, or restaurants are ridden with efficiency-related issu...

Hygiene washer for food utensils

Thorough and quick cleaning of kitchen utensils, such as baskets, knives, trays, and other ...

Tunnel washer for food containers

With an increase in demand for production across food service and manufacturing companies...

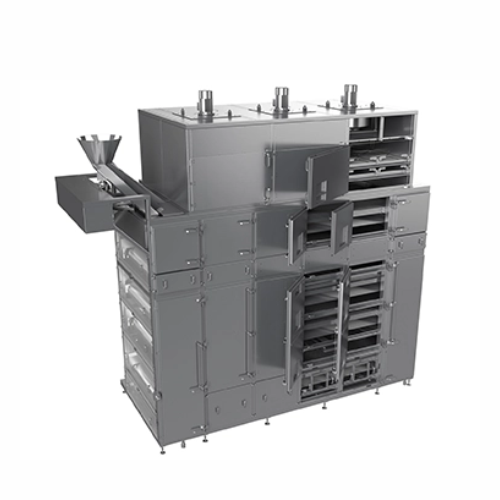

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Industrial crate washing machine

In order to meet the increasing demand of the beverage industry, it’s essential to find a c...

Automatic freeze drying system

Freeze drying can be an expensive and cumbersome process. When dealing with nutraceuticals it...

Hygienic vertical bagging machine

Hygienic bagging with a compact packing machine that can withstand the harshest wash down...

Continuous dryer machine

Traditional drying methods in the pet food, aquafeed, and extruded food industry can be the most ene...

Conveyor belt metal detector for food products

Inspecting and rejecting finished food products for metal contamination is ...

Standalone metal detector for food

Adding advanced metal detection to existing lines can be difficult and expensive, often ...

Industrial dehydration machine

Dried fruits are popular both as food in themselves and as ingredients. Traditional drying te...

Hygienic belt dryer

A belt dryer typically applies the product through an infeed chamber onto a perforated horizontal belt, w...

Air dehumidifier for bulk products

When your product or process is sensitive to humidity, using an air dehumidifier may res...

Metal detection system

The inspection system automatically determines the best frequencies to maximize sensitivity for both f...

X-ray inspection system for processed meat products

When dealing with the poultry industry, the Dual X-ray inspection sys...

High sensitivity X-ray inspection system

This is the X-ray inspection system you need for detecting contaminants that are d...