Making Canola Meal

Find innovative production technology for making canola meal and connect directly with world-leading specialists

The name Canola comes from ‘Canadian Oil Low Acid’. In the 1970s researchers in Canada developed rapeseed varieties with low erucic acid and glucosinolate. These properties made the seed safe for consumption while improving its palatability. Today, the varieties are grown worldwide and include the rapeseed double-zero, as it is known in Europe. In only a few decades, canola oil and canola meal processing carved out a central role in the global food and feed industry.

Technology picks for canola meal production

Oilseed screening solution for soybean and canola

Optimize your grain and oilseed processing with a high-throughput scree...

Efficient dryer-cooler for solvent-extracted meals

Optimize moisture control and energy efficiency in your production lin...

Efficient desolventization and toasting solution for oilseeds

Optimize solvent removal and toasting in your oilseed proc...

Cold press for extracting vegetable oils

Efficiently extract high-quality oils from diverse seeds while preserving vital nu...

Tell us about your production challenge

Canola meal is a high-value addition to feeds

Canola meal is a byproduct of canola oil extraction. Rich in amino acids and containing around 36% of crude protein, canola meal enhances the nutritional value of feed.

After harvesting, the seeds are cleaned by a series of sieves to eliminate residual dirt. At this point, the plant material is ready for processing.

Improve oil extraction for canola meal processing by pre-heating the seeds

There are several methods of canola meal manufacturing. The most common is to heat the seeds and pass them through rollers, turning them into flakes. Next, cook the seeds to release the oil.

This facilitates extraction when the seeds go into the extruder or screw press. This process produces a canola cake as a co-product. Treat the cake with hexane, a solvent that removes left-over oil, and, after withdrawing the solvent, toast the cake to dry it. The cake is now ready to be ground into canola meal.

Cold-press the seeds to retain higher nutritional value

A solvent-free alternative to obtaining canola meal is to pass the cake through the screw press a second time after filtering.

And if you want to avoid heating the seeds to preserve the nutrients to the maximum, you can cold-press them, extracting the oil mechanically and slowly to avoid the heat by friction. This produces a higher oil content in the meal, but the crude protein will be slightly lower.

Potential applications for canola meal as protein and novel food

The high content of crude protein and amino acids make canola meal an excellent option for dairy livestock, fish, swine, and poultry. But beyond feed, canola meal is finding its way into novel foods. After further processing, it may be used as protein for food supplements and other foods, including vegan preparations, plant-based meat, and plant-based dairy alternatives.

Processing steps involved in canola meal making

Which canola meal technology do you need?

Batch weighers for large-volume powder and granulate weighing

Ensure precise ingredient dosing and streamline your produ...

Single conditioner for feed mills

Achieve homogeneous mixing and enhanced hygiene in feed production with adjustable paddle...

Roasting and pasteurization system for nuts and seeds

Ensure optimal pasteurization and roasting of nuts, seeds, and drie...

Oilseed cooker/conditioner for optimal seed preparation

Achieve consistent oil extraction and enhanced product quality wi...

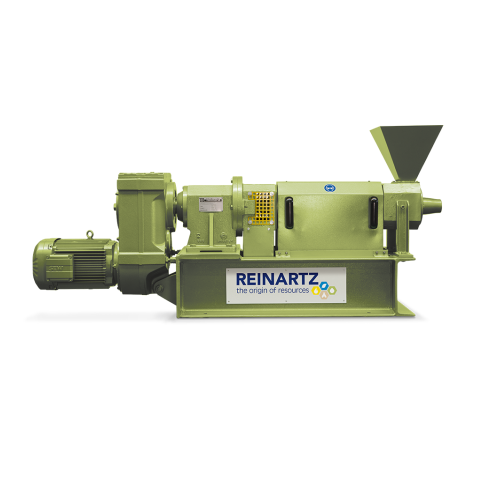

Oil presses for oilseed extraction

Ensure efficient oil and protein extraction with specialized presses, enabling optimal s...

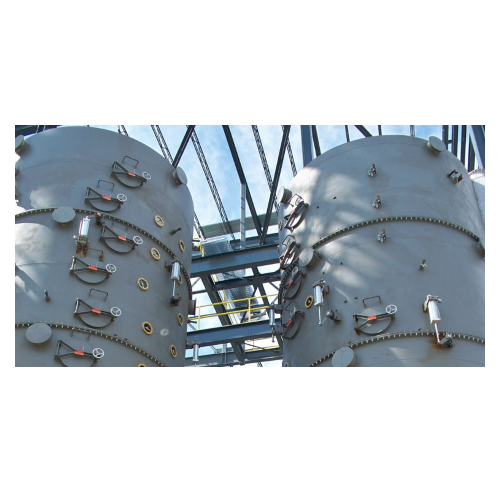

Vertical seed conditioning system for oil extraction

Ensure optimal oil yield and quality from oilseeds by employing a ve...

Efficient desolventization and toasting solution for oilseeds

Optimize solvent removal and toasting in your oilseed proc...

Efficient dryer-cooler for solvent-extracted meals

Optimize moisture control and energy efficiency in your production lin...

Dryer-cooler for solvent-extracted meal

Achieve optimal moisture and temperature control for solvent-extracted vegetable-oi...

Industrial feed conditioner for optimal moisture absorption

Achieve precise control of moisture and temperature to enhan...

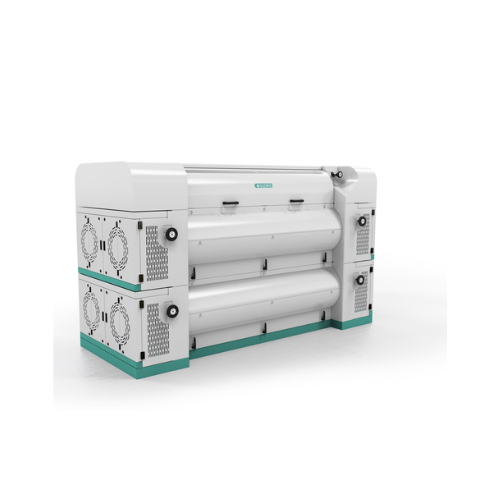

Oilseed cracking solution

Maximize throughput with precision cracking, ensuring optimal downstream processing for oilseed pr...

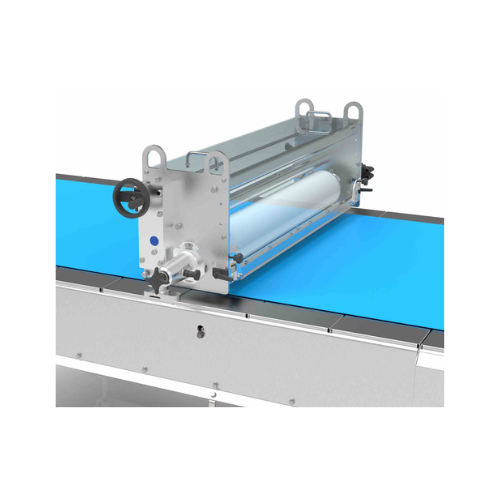

Oilseed flaking mill

Enhance flake consistency and output efficiency with advanced roll technology designed to optimize your ...

Impact dehuller for sunflower, soybean, and cottonseed

Enhance oil extraction efficiency with a dehulling solution that g...

Cracking mill for oilseeds and feed

Enhance your production efficiency with a cracking mill that optimizes throughput and m...

Soybean dehulling separator

Enhance the quality of your oilseeds and grains by efficiently separating hulls and impurities, ...

Cracking mill for oilseeds and feed processing

Maximize your production efficiency with advanced cracking and milling solu...

Continuous dryer machine

Traditional drying methods in the pet food, aquafeed, and extruded food industry can be the most ene...

High volume particles separation sieve

For large scale production processes in the chemicals or food industries that requir...

Screener and separator of dry powder

Many industries require the effective screening and separating of a range of dry powde...

Automatic stretch wrapping machine for medium speed

For secure, automated stretch wrapping at medium speeds, the key is e...