Making Sea Buckthorn Oil

Find innovative production technology for making sea buckthorn oil and connect directly with world-leading specialists

The ancient Greeks believed feeding sea buckthorn to their horses would give them a lustrous hide. Indeed, full of lipids and carotenoids, the fruit did contribute to glowing, reddish coats. However, the thorny plant also has benefits for humans. Sea buckthorn processing equipment extracts this unique vegetable oil full of fatty acids. The liquid is a prominent component in various food, cosmetic, and pharmacological preparations.

Select your sea buckthorn oil process

Tell us about your production challenge

Pass the unprocessed sea buckthorn through dewatering equipment

You may process sea buckthorn oil either from the berry or its seeds. Each has its distinct processing method, but you must wash the plant material from soils, insects, and other residues in both cases.

However, the raw material must go dry for further processing. Use a dewatering conveyor and subject the wet plants to an air knife or evaporator system to break droplets and remove any water from the surface.

Centrifuge the sea buckthorn fruit juice to obtain the oil

The pulp of the sea buckthorn has between 8 and 12 weight percentage in oil, with a high fatty acid content compared with other vegetable oils.

Pressing the berries to extract a mixture of juice and oils. Clarify the contents in a clarifier unit to remove particles and natural sediments. Finally, centrifuge the liquids to separate the juice from the oil. Sea buckthorn oil from pulp has a high density and thickens when refrigerated.

Extract seed oil with supercritical processing technology

Sea buckthorn oils extracted from the fruit are rich in monounsaturated fatty acids. Oil from its seeds, however, has a high content of polyunsaturated acids.

Dry the fruit and sieve to separate the fibers from the seeds. One extraction method involves treating the material with supercritical carbon dioxide. The fluid breaks down the seed matrix and releases the lipids. The CO2 will turn into a gas when it returns to room temperature, leaving only the seed oil behind.

Sea buckthorn oil processing for cosmetic and nutritional applications

Sea buckthorn oil includes several bioactive ingredients that lock in skin moisture, making it a popular base in the manufacturing of cosmetic products.

But a range of compounds such as flavonoids, antioxidants, and vitamins have turned sea buckthorn oil into an ingredient of interest for the nutrition industry. In particular, the formulation and processing of nutraceuticals are turning to the plant to develop new products.

Processing steps involved in sea buckthorn oil making

Which sea buckthorn oil technology do you need?

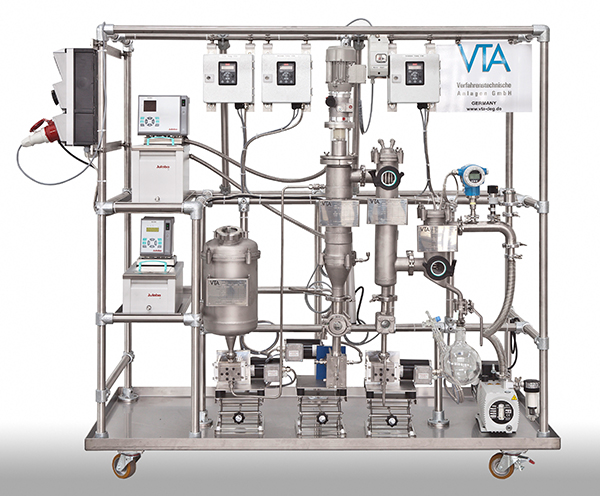

Decarboxylation package for botanical extraction

Optimize decarboxylation and reaction processes with precise temperature ...

Linear automatic bottling machine for liquids

Autonomous filling systems are a very widely utilized solution for the consi...

Bottle filling and capping monobloc

Spillage and overfilling are common problems in most production lines for bottled produ...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

Sunflower oil extraction plant

Extracting sunflower oil using an organic solvent, usually hexane, has a big environmental im...

High speed bottle filler with inspection

Medicines in tablet, capsule, or soft gel forms undergo various processes before r...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Industrial bottle sterilizer

Sterilization is an important process in the beverage industry to kill microorganisms. It is im...

Continuous dryer machine

Traditional drying methods in the pet food, aquafeed, and extruded food industry can be the most ene...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

High-end empty bottle inspection system

If you are looking for a system with empty bottle inspection; base, residual liquid...

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

Customizable dehumidifier

Dehumidification needs can vary significantly from one project to another. Dehumidifiers with a fi...

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

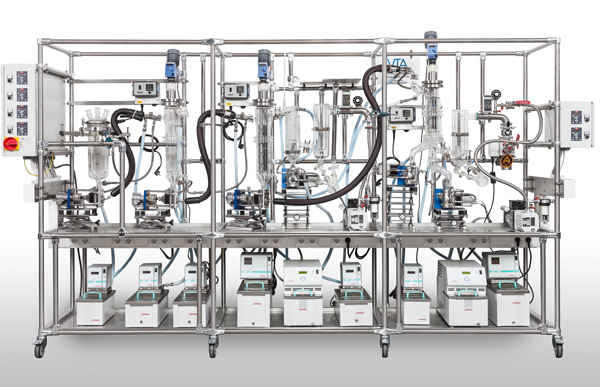

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory wiped film distiller

Reach reliable conclusions testing the distillation of high-boiling or highly viscous materi...