Find technology for processing vegetable powders

Find innovative production technology for making vegetable powder and connect directly with world-leading specialists

This powdery food made of dehydrated and ground vegetables is a great way to preserve flavor and nutrition for a long time while still having the benefits of eating fresh vegetables. It is beneficial to turn seasonal vegetables into powders for all-year-round use. Certain vegetable powders, known as green powders, are especially popular as dietary supplements and are used in smoothies for racing a recommended daily intake of vitamins and minerals. Furthermore, vegetable powders can be added to foods as coloring, for instance, in baked goods or to pasta sauces and omelets.

Stories about vegetable powder

Tell us about your production challenge

Select and inspect your vegetable quality first

Inspect your vegetables manually or with automatic sorting and inspection technology for surface damage, signs of spoilage, and contamination. Mature vegetables with a bright color and characteristic flavor are the key characteristics of a high-quality vegetable powder. Once the high-quality vegetable is selected, stems, leaves and other inedible parts need to be removed, and the edible parts must be washed in clean water while rubbing and brushing against all cavities to ensure hygienic standards. Furthermore, adding sodium hypochlorite and sodium bicarbonate removes dirt and microorganisms.

Blanch in distilled water for 15 seconds to prevent color, texture, and flavor loss

Depending on the type of vegetable, one of the preprocessing steps is blanching in distilled water for up to 15 seconds, usually applied for solid vegetables such as celery or cabbage, but is not necessary for vegetables with a high liquid ratio such as tomatoes or cucumbers, due to their tender structure and ability to store well. Blanching stops enzymic processes that make vegetables lose color, texture, and flavor once processed.

Pulp or cut your vegetables before drying, grinding, and finishing them

There are two different production processes for vegetable powder. The difference between the processes comes after cleaning and blanching when a manufacturer can either pulp or cut the vegetable before drying, grinding, and finishing. Different cut and slicing tools are available to automate your process. Alternatively, vegetables are first turned into pulp in a vegetable pulping machine and then cut. Nutrient value is maintained by avoiding high temperatures or soaking in water for too long and choosing the most suitable drying method.

Which drying principle fits your vegetable powder processing needs?

There are, however, different drying methods that can be used. Starting with the spray drying process which is a free-flowing, micro-safe process suitable for use in the production of spices, flavorings, and medical ingredients. This method requires vegetables to be processed into pulp before drying, which is then dispersed by atomizers or spray nozzles at very high temperatures to create controlled drop-size spray. Alternatively, hot air drying is a cost- and time-effective method that results in a product that is easy to ground and has nicely preserved color. It uses hot air drying machines that commonly operate at 60°C.

Vacuum dry your temperature- and oxygen-sensitive vegetables

The main characteristics of vacuum drying are higher drying rate, lower drying temperature, and oxygen-deficient processing environment. This method lowers the pressure and, therefore, the boiling point so vegetables can be dried at lower temperatures in a closed vacuum. In addition, vacuum drying requires less time than other drying methods. Notably, the absence of air prevents oxidation, which ensures the maintenance of color, texture, and flavor. Due to these traits, vacuum drying minimizes the possibility of oxidation reactions and is ideal for temperature and oxygen-sensitive materials. This is a time-consuming and cost-effective process.

Freeze-dry your peas, carrots, potatoes, and beans

In the freeze-drying method, also known as lyophilization, the frozen raw vegetable is dehydrated in a refrigerated vacuum system without previous tawing, having the ice sublimated into water vapor. In other words, in a freeze dryer, water content in vegetables goes from split to vapor and skips the liquid state. This method is very simple and exceptionally good at preserving color, shape, flavor, and nutritional value. Freeze-dried powders are very lightweight and with exceptionally long shelf-life. Some vegetables suitable for this method are peas, carrots, potatoes, beans, etc.. However, vegetables with high fat- or water content might not be suitable for this drying process. Although a simple process, it lasts longer than vacuum drying, but it preserves maximal nutrients.

Unlock the versatility of vegetable powders

There are numerous applications of vegetable powders, from the beverage industry with protein-based soli beverages and sports solid drinks, over the food industry to the pharmacy. Even within only one industry, it being food, there is a wide range of applications, namely, from baby food to snacks and sweets, or as a coloring agent in bakery goods due to the decreasing popularity of artificial colorings. Furthermore, vegetable powders can even be used as thickening agents in soups or sauces as an alternative to starches. In addition to the food industry, vegetable powders are also in increasing use in the pharmaceutical industry as they strive to use more natural products, especially for supplements, as well as in the cosmetics and skin-care industry, as it is full of antioxidants. Although vegetable powders are a great addition to the diet, they can not fully substitute fresh vegetables. However, their advantage is being very easy to use by simply adding it to a smoothie or meal for a nutrient-dense vitamin kick, as well as the long shelf life compared to fresh vegetables.

Bring the beet in

A buzz-worthy product in the market is beetroot powder, appraised for its natural sweetness, color, and health benefits deriving from the high nitrate content. Therefore it is useful for heart, gut, and brain health. The powder can be added to smoothies, soups, and sauces. But there is more: it is also utilized in cosmetics. Beetroot powder gives a vibrant color to vegan or nature-based blushes, lipsticks, and eyeshadows. This demonstrates that beetroot powder can be utilized beyond the food industry, and also in cosmetics and pharmaceuticals. Thus it is important to note that the estimated value of the vegetable powder market in 2023 will be 7.3 billion dollars, and it is expected to reach 12 billion in the next ten years.

Which vegetable powder technology do you need?

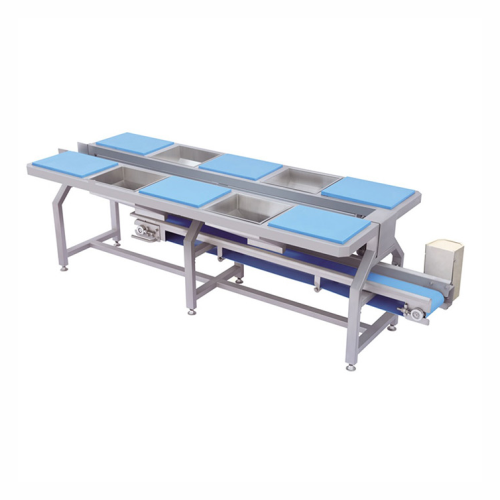

Vegetable and fruit preparation table

Optimize your food processing line with a versatile preparation table designed for ef...

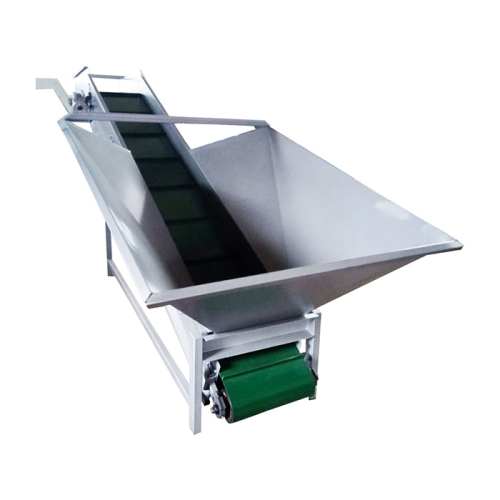

Receiving hopper for jumbo boxes

Efficiently unload and handle bulk agricultural products with ease, streamlining your pre-p...

Multifunction vegetable fruit slicing solution

Streamline your food processing with a machine that effortlessly slices, di...

Vegetable and fruit centrifugal slicer and shredder

Enhance your food processing with high-capacity slicing and shredding...

High-volume oilseed extraction system

Achieve optimal extraction efficiencies with a versatile system that handles various ...

Enzymatic inactivation system for fruits and vegetables

Achieve optimal product quality by maintaining vivid color, robus...

Industrial vegetable blanching solution

Achieve unparalleled efficiency and precision in food processing with this advanced...

Heater for enzymatic inactivation of fruit and vegetable pulp

Optimize your puree and concentrate production with effici...

Frozen extraction turbo extractor for fruit and vegetable purees

Efficiently transform frozen fruits and vegetables into...

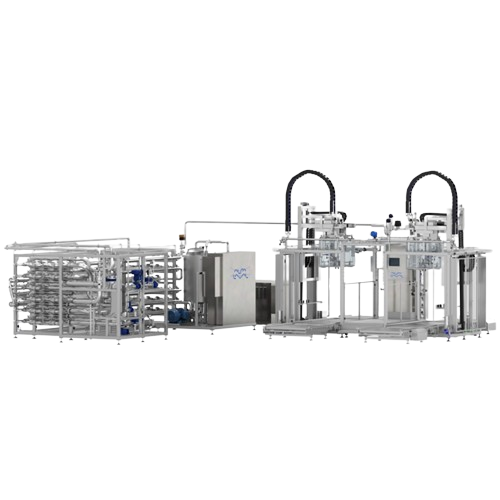

Aseptic processing equipment for food products

Optimize aseptic processing to ensure microbiological stability and product...

High speed fruit and vegetable juicer

Optimize your production with a high-capacity juicer designed to efficiently process ...

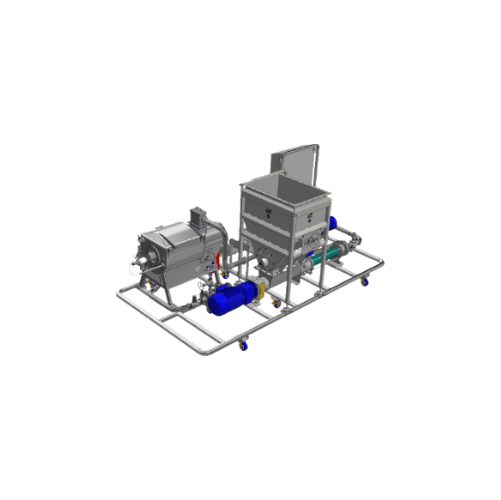

Vegetable and fruit processing skid

Optimize your fruit and vegetable processing with a compact skid that seamlessly integr...

Industrial multifiller for fruit and vegetable salads

Need to efficiently fill diverse containers with fruit and vegetabl...

Food dehydrator with Bpa-free trays

Effortlessly retain nutrients while creating a variety of dehydrated snacks using dual ...

Vegetable cutter for industrial kitchens

Effortlessly achieve uniform cuts of fruits and vegetables in industrial kitchens,...

Multi-function vegetable cutting machine

Effortlessly transform a variety of fruits and vegetables into precise shapes and ...

Mesh belt food dryer

Achieve uniform and efficient drying of diverse materials with the mesh belt food dryer, designed to max...

Spiral washer for cut vegetables

Optimize washing efficiency for cut and leafy vegetables, both floating and sinking, with a...

Carrot topping and cutting system for high-capacity processing

Optimize your carrot processing with a high-speed system ...

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Pilot scale freeze dryer

Freeze drying is a complex and time-consuming drying process which requires maintaining the quality ...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

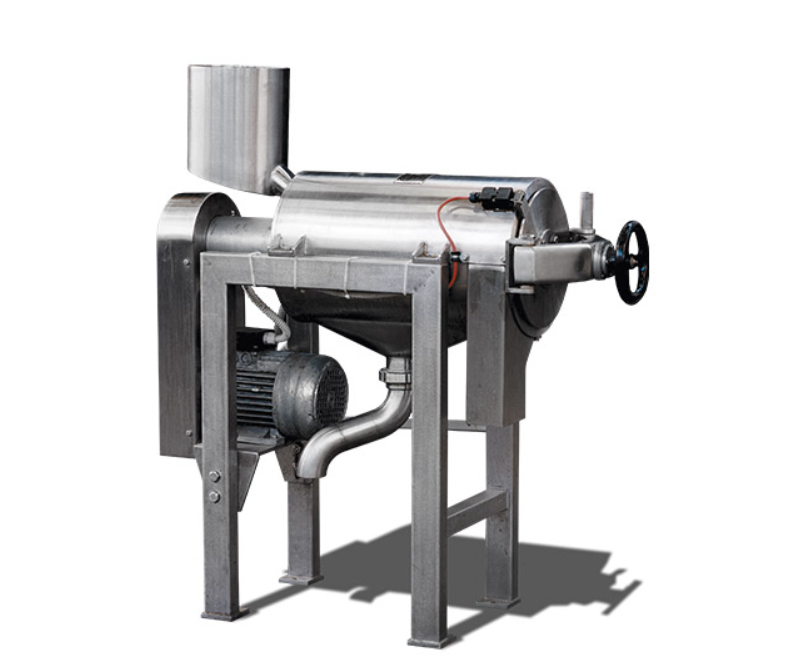

Fruit pulping machine

When making fruit pulp, a pulping machine helps you remove seeds, stems, and skins from your fruit. How...

Infrared rotating drum steriliser

Sterilisation of foodstuffs is vital to maintain uncompromising standards of hygiene and ...