Let's make organic fertilizer

Find innovative production technology for making organic fertilizer and connect directly with world-leading specialists.

Organic fertilizer production has ancient roots, tracing its origins to ancient farmers who used natural materials like animal manure, compost, and crop residues to improve soil fertility. This sustainable tradition of repurposing organic waste for agricultural benefits has endured through the ages, handed down from one generation of farmers to the next. Producing organic fertilizer industrially involves a series of steps such as extraction, granulation, drying, and employs a combination of organic fertilizer production equipment.

What are you making?

Tell us about your production challenge

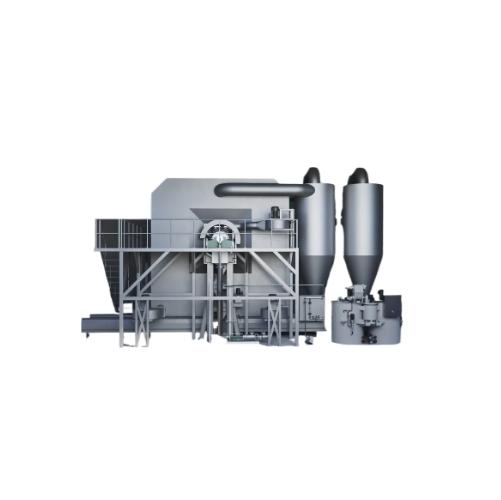

Upon arrival at the factory, the producers collect and mix various raw materials, storing them in bulk. Subsequently, the materials undergo a stimulating transformation, kickstarting the composting process. Precise control of oxygen levels and temperature ensures the creation of a stable product. Once ready, conveyors transport the composted materials to the dryer at a temperature of approximately 180 degrees.

After this drying stage, the raw materials proceed to the conditioner. The raw material undergoes controlled heating above 70 degrees in the conditioner, effectively eliminating all harmful pathogens. Following this critical step, the material is conveyed to the hammer mill, which is compressed into pellets measuring between 3.5 to 5 mm in thickness. The final touch is packaging, managing the final product for distribution in bags or bulk bags. This meticulous process culminates in producing high-quality organic fertilizer, ready to nourish and enrich soils, propelling agricultural success.

Drying granular fertilizer with fluid bed technology

Organic fertilizer is available in liquid and dry formulations, offering distinct advantages. Dry fertilizer, in particular, exhibits a gradual nutrient release, providing plants with nourishment over an extended period. As a consequence, it is the favored choice when dealing with extensive areas requiring fertilization.

Fluid bed dryers are generally used to dry wet granular materials in one of the last steps of the organic fertilizer production process. This fertilizer drying machine works on the principle of fluidization, whereby solid particles are made fluid. Hot air is blown in the machine to dry the wet granular fertilizer, passing air through the particles. The speed of the air lifts the product, converting it from a solid-like state to a fluid-like state. The shaking movement of the machine up and down improves this effect. At this point, the suspended product seems to be a bed of fluid. The direct contact of each particle with the hot air maximizes heat transfer and creates uniform and efficient drying.

Dried and pelleted manure as a valuable fertilizer

Poultry manure, though potent in nutrients, presents challenges with its unpleasant odor, fly attraction, and ammonia emissions, posing environmental risks. However, a transformative solution lies in drying the poultry manure, effectively enriching its nutrient value and significantly reducing odors, fly infestations, and ammonia emissions, offering a substantial ecological benefit.

Moreover, the advantages don’t end there. The drying process also reduces the weight of the manure through moisture removal, leading to reduced volume and lower transportation costs. To further enhance its value, pelleting ensures a uniform product that is easier to handle, store, and efficiently spread onto the soil, fostering a seamless and efficient agricultural experience.

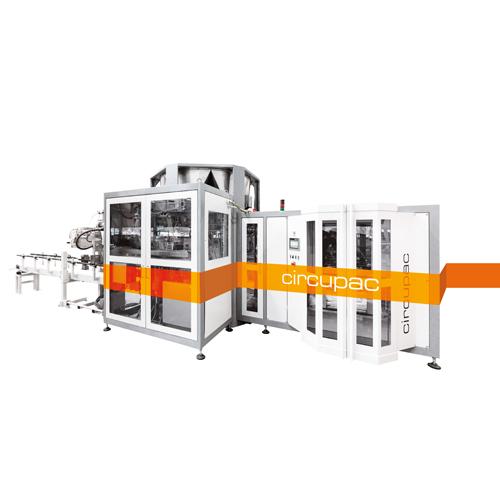

How to pack your fertilizer safely?

The bagging process stands as the preferred method for packaging organic fertilizer, encompassing crucial stages of feeding, weighing, filling, and sealing. Accurate weighing and dosing are paramount to ensure consistent and precise portions of the product in each bag. Subsequently, the filling system carefully funnels the measured content into the bags.

In the packaging, safeguarding the product from external elements remains paramount. Thus, tight and secure sealing of the bags is essential. To ensure durability and resistance against corrosion, the fertilizer packaging equipment components that come into contact with the product are crafted from stainless steel.

Moreover, the welfare of operators is diligently considered, as dust emissions can pose respiratory risks. Hence, an automatic bagging process is pivotal in minimizing dust release, and maintaining a hygienic and dust-free environment, thereby safeguarding the health of those involved.

Which organic fertilizer technology do you need?

Biogas plant screw press separators

Maximize your renewable energy output and processing efficiency with cutting-edge solid...

Evaporator for manure fertilizer

Traditionally, liquid manure processing can lose some important nutrients. An efficient ful...

Belt dryer for digestate

The drying of poultry manure digestate requires careful and consistent moisture level control. A sus...

Vertical mixers for animal feed industry

Efficiently combine a variety of powdered and raw materials with precision, ensuri...

Manure biogas plant for agricultural sector

Transform animal waste into renewable energy and nutrient-rich bio-fertilizer,...

Organic waste biogas plant

Transform abundant organic waste into renewable energy and valuable byproducts with a high-effici...

Carbon/nitrogen analyzer for organic samples

Optimize your lab’s efficiency with fast, reliable nitrogen and carbon ...

Biomass drying solution

Achieve efficient and gentle biomass drying with innovative heat exchange technology, ensuring optima...

Biosolids granulator for waste treatment

Transform raw sludge into valuable granules with a solution that securely dries an...

Manure decanter for nutrient separation

Transform livestock manure into valuable resources by efficiently separating and ex...

Manure treatment system for livestock breeding

Optimize waste-to-value processes with advanced systems designed to efficie...

Dewatering solution for spent grain

Achieve efficient moisture reduction in spent grains with this continuous mechanical sc...

Bead mill for crop protection

To optimize qualities like particle size, distribution, solubility, and miscibility of active ...

Exergy pressurized superheated steam dryer

Traditional dryers and heat transfer systems, like belt-, drum- or bed dryers a...

Classifier mill for powder coating

High-quality powder coatings are often required to manufacture equipment, appliances, an...

Open mouth bag filling machine for powders

The packaging of powdery products such as flour can be challenging as it is cru...

Pelleting line for manure fertilizer

Manure fertilizer needs to be made marketable by making them visually attractive, with...

Continuous fluid bed dryer

In a Fluid Bed, a product or solid is made fluid by an upward moving flow of gas. The mechanical ...

Vertical form, fill and seal machine for bags from 5 to 50 kg

To securely create, dose and pack larger quantities of mat...

Automatic bagging machine for open mouth bags

Open mouth bags allow for a variety of different products to be packaged, wi...

Small scale pelleting press

Many industries require reliable pelletizing equipment with smaller scale production capacities....