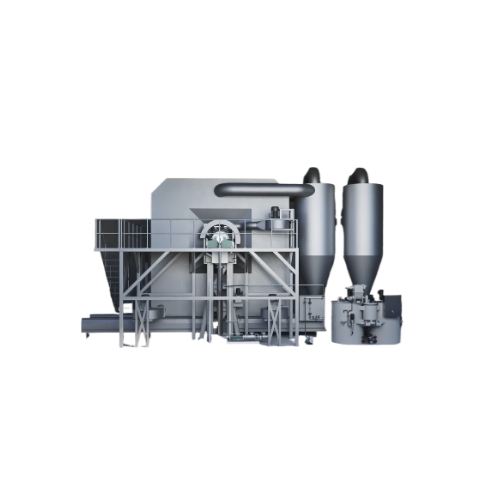

Biosolids granulator for waste treatment

Transform raw sludge into valuable granules with a solution that securely dries and granulates biosolids, minimizing pathogen regrowth while efficiently utilizing waste heat for energy conservation.

Granulates and Dries Biosolids Efficiently

The GEA Biosolids Granulator is engineered to transform dewatered municipal and industrial sludge into valuable granulated end-products. By employing a unique multi-stage drying and granulation process, it ensures pathogen reduction and produces granules suitable for agricultural and industrial applications, including fertilizer and fuel additives. This system integrates efficiently into existing processing lines and features a continuous, automated operation that is ideal for large-scale treatment facilities. The granulator makes use of waste heat or fuel sources for energy-efficient operation while maintaining consistent output quality. Constructed with durable materials for enhanced longevity and low maintenance, the equipment supports sustainable recycling pathways and reduces environmental impact.

Benefits

- Converts waste into revenue-generating products like fertilizer and fuel pellets.

- Lowers energy costs by utilizing available waste heat in drying processes.

- Minimizes pathogen regrowth, ensuring safer agricultural applications.

- Supports sustainable practices with continuous, automated operation.

- Reduces environmental footprint by enabling recycling in limited disposal settings.

- Applications

- Environmental protection, Agricultural land, Biosolids, Industrial waste water, Water treatment, Fuel additive, Composting, Municipal sludge

- End products

- Agricultural fertilizer granulate, Granulated biosolids, Dried sludge granulate, Industrial sludge granulate, Water treatment sludge granulate, Compost enhancer pellets, Fuel pellets

- Steps before

- Dewatering, Thickening, Sludge Collection

- Steps after

- Recycling, Composting, Incineration, Agricultural Application

- Input ingredients

- raw sludge, municipal sludge, sludge from industrial waste water, sludge from water treatment plants

- Output ingredients

- biosolids granules, dried granulated material, recycled biosolids, agriculture compost, fuel additive

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Dry solids content

- Up to 50%

- Pathogen count

- Below 100, 000 cfu/g

- Heat source temperature

- 75–90°C

- Drying method

- Direct heat injection and secondary hot airflow

- End product particle size

- Small, consistent

- Working mechanism

- Centrifuge-based drying

- Heat source

- Low-grade waste heat / Fuel

- Drying method

- Direct heat injection

- Particle size

- Small, consistent

- Pathogen control

- Sustained count below 100, 000 cfu/g

- Resistance to degradation

- Weather-resistant end product

- Automation level

- Continuous process

- End product use

- Agriculture, composting, incineration

- Corrosive resistance (e.g. acids)

- Limited re-infection risk

- Biological resistance

- Sustained pathogen count below 100, 000 cfu/g

- Thermal stability

- Utilizes low-grade waste heat (75–90°C)

- Humidity resistance

- End product resists degradation due to weather

- Recycling applications

- Agriculture, Composting

- Machine footprint

- Compact design

- Centrifuge bowl shape

- Horizontal solid-wall

- Feed/discharge method

- Direct eject from centrifuge

- Particle size

- Small, consistent

- Main drying chamber

- Includes secondary hot airflow

- Heat Source

- Low-grade waste heat / Fuel source / Combination

- Automation Level

- PLC-controlled / SCADA integration

- Drying Performance

- On-demand customization

- Particle Size Control

- Consistent small particle size