Making Elderberry Extract

Find innovative production technology for making elderberry extract and connect directly with world-leading specialists

Elderberry falls squarely in the category of superfoods. Every part of the plant (flowers, berries, and bark) is loaded with vitamins, antioxidants, bioflavonoids, and other compounds. However, cyanide in the plant could be lethal if consumed raw, making elderberry extraction processing complex.

Select your elderberry extract process

Tell us about your production challenge

Alternate the temperatures during freeze-drying to produce larger crystals

The bioactive compounds in elderberry are sensitive to heat and may become unstable in solvent mixtures. By sublimating the material during lyophilization with a freeze-dryer, you isolate the more sensitive natural substances to a finer degree.

Cool the material below its triple point, the lowest temperature at which liquid and solid phases may coexist. This will cause sublimation in subsequent phases rather than melting. Larger crystals freeze-dry more evenly. To produce larger crystals, cycle the temperature up and down.

Apply solvents with a high dielectric constant for Microwave-assisted extraction

Microwave-assisted extraction requires a shorter extraction time than traditional processes while using less solvent. Microwave radiation heats the plant material, directly breaching the substrate’s cell wall.

The compounds escape into the solvent while any leftover moisture evaporates by the generated heat. Their high dielectric constant and microwave absorption capacity make acetone, glycerin, and ethanol suitable MAE solvents.

Anthocyanin stability determines the quality of the elderberry extraction process

The quality of elderberry extracts is measured by the high stability of anthocyanins and a low degree of microbial impurities. The anthocyanins and other flavonoids cause an antioxidant effect by reducing free radicals in the body.

Elderberries also host a range of microbes that may be pathological. But the microbial content in elderberry extracts is typically low.

Sucrose alternatives in elderberry extract processing

Extra-fine granulated sucrose has a high water retention rate that gives elderberry gummies structure. Besides sweetness, it adds the plasticity and bulk that give gummies their chewy mouthfeel.

But a trend away from sugar ingredients means that formulations rely on polyols to achieve the same texture. Most polyols, such as hydrogenated starch hydrolyzates, have a high affinity for water and require a higher gelatin concentration than in sucrose-based recipes.

Processing steps involved in elderberry extract making

Which elderberry extract technology do you need?

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Benchtop peristaltic dispenser

When you fill vials and ampoules, high standards of hygiene are required to avoid the risk of...

Benchtop piston filling equipment for vials in trays

Vials are difficult to fill individually through manual methods due ...

Semi-automatic vial crimper

In a small production line, crimping vials manually can cause fatigue to your operator due to mu...

Ultrasonic barbell for extraction

Conventional extraction methods are time-consuming, labour-intensive and can sometimes be...

Vacuum cabinet dryer for plant extracts and functional foods

Plant extracts are vital to functional food preparations. B...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

Evaporation plant for the recovery of extracts

Bespoke evaporation plants using the latest plate evaporation technology ca...

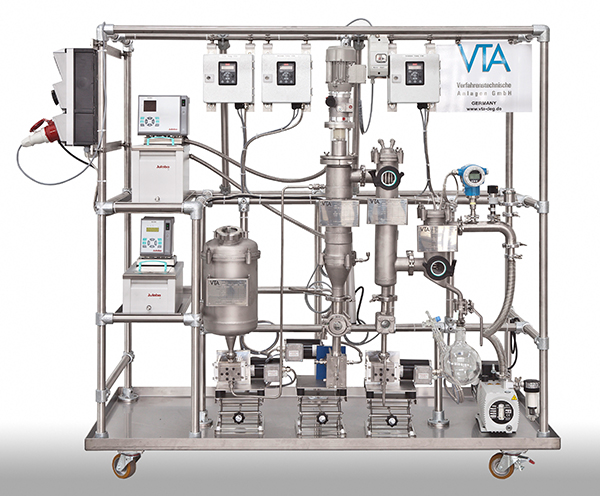

Pilot evaporation plant for the recovery of extracts

For development of concentrates of extracts based on water or ethano...

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

Laboratory short path distiller

Get to reliable conclusions for the separation of high-boiling and heat-sensitive products u...

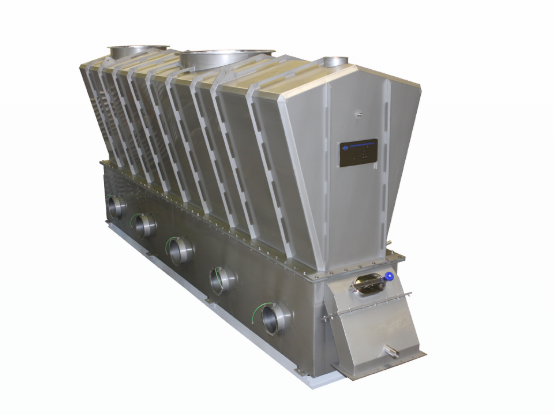

Horizontal thin film evaporators

Horizontal thin film evaporators can increase the residence time of the product and achieve...