Pvc pipes

Find innovative production technology for making pvc pipes and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Processing steps involved in pvc pipes making

Which pvc pipes technology do you need?

Plastic pellets inspection system

Ensure product quality by accurately detecting impurities and variations in plastic pelle...

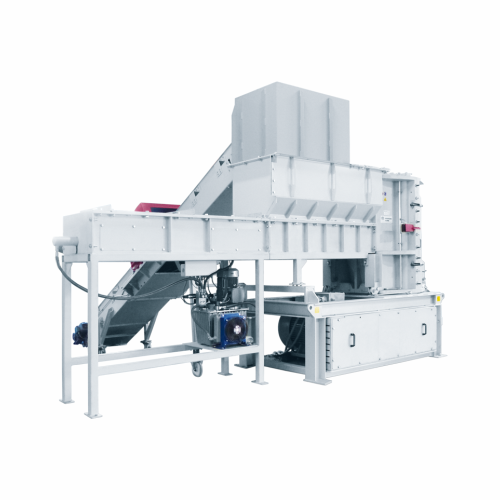

Shredder-granulator for plastic recycling

Simplify your plastic recycling process by integrating shredding and granulating...

Industrial granulators for plastic recycling

Streamline your recycling operations with a solution that not only reduces en...

Air pelletizer for wood and natural fiber compounds

Optimize your pelletizing process with air-based cooling and conveyin...

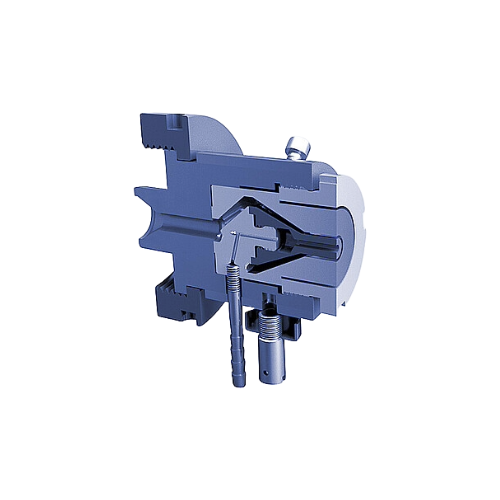

Continuous screen changer for thermoplastic materials

Eliminate downtime caused by blockages with a continuous screen cha...

Precision feeders and mixers for plastics processing

Achieve precise blending and feeding for plastics processing with mo...

Gravimetric batch blender for plastics compounding

Achieve precise batch blending with high accuracy, ensuring consistenc...

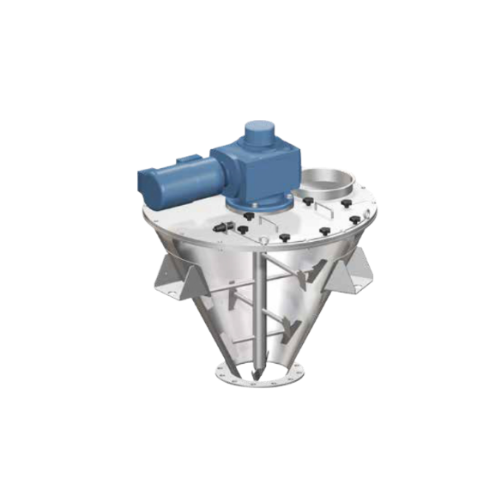

Feed bins for pre-conditioning materials

Optimize your material flow by pre-conditioning bulk solids for efficient vacuum c...

Tubing die head for pipe extrusion

Optimize your extrusion process with versatile die head options for producing high-quali...

Modular torque rheometer for plastics and plastifiable substances

Optimize your material development and testing with a...

Modular torque rheometer for polymer testing

Gain deep insights into the processability and material characteristics of po...

Planetary mixer for homogeneous material mixing

Achieve precise and consistent mixing of diverse materials from powders to...

Conical twin screw extruder for shear-sensitive materials

Optimize the extrusion process for shear-sensitive materials w...

High efficiency central chiller for industrial cooling

Achieve remarkable energy savings with this modular chiller system...

Powder hopper loaders for free-flowing materials

Efficiently transport free-flowing powders, including PVC and polyethylen...

Central chiller for consistent process cooling

Optimize your production with modular central chillers offering scalable co...

Stainless steel drying hoppers for plastic processing

Optimize moisture control for thermoplastics with robust drying hop...

Digital doser system for plastics additive feeding

Achieve precise additive dosing for plastics, ensuring consistent qual...

Hot air dryers for non-hygroscopic material

Ensure reliable material quality by effectively reducing moisture in non-hygro...

Automated process controllers for industrial plants

Enhance your production line’s efficiency and adaptability with...

Negative pressure filter for fine dust particles

Ensure efficient air purification and dust collection in your production ...

High-speed paddle mixer for food industry blends

Achieve rapid, high-energy blending of varied particulate materials with ...

Battery production facilities with precision weighing

Achieve maximum product purity and precision in your production pro...

Membrane pressure relief valve for silo protection

Ensure immediate pressure stabilization in your bulk storage silos wit...

Pipe couplings for pneumatic conveying lines

Ensure a secure and quick connection for your pneumatic lines with these pipe...

Vacuum dissolving system for high-viscosity products

Achieve flawless dispersion of high-viscosity substances under vacuu...

Continuous cooling roller for extrudates

Ensure rapid and efficient cooling of high-heat capacity extrudates with a compact...

Industrial dust collection system

Optimize your process by efficiently capturing and removing airborne dust particles, ensu...

Powder flow measurement system

Achieve precise control over powder consistency and prevent process disruptions by assessing ...