Making Ginkgo Extract

Find innovative production technology for making ginkgo extract and connect directly with world-leading specialists

What’s the only living connection between our present world and the age of dinosaurs? The ginkgo biloba plant. Also known as the maidenhair tree, it is regarded as a living fossil and has been around for more than 200 million years. Ancient civilizations in China were already mastering ginkgo processing centuries ago and the tradition soon flourished around the world.

Select your ginkgo extract process

Tell us about your production challenge

Falling film evaporators concentrate components in gingko processing

A falling film evaporator pumps heating fluid through a heat exchanger, transmitting thermal energy to the ginkgo plant material and vaporizing the solution. The technology concentrates the heat-sensitive components in the extracts.

The concentrate evaporates with the interface of liquid and vapor and prevents the formation of crystals.

Deep eutectic solvents (DES) reduce the ecological impact of extraction

Green chemistry is developing Deep Eutectic Solvents (DES) to reduce the environmental impact of solvent extraction methods.

DES are biodegradable liquids produced by combining hydrogen bond acceptors such as quaternary ammonium salts with hydrogen bond donors. Extraction using DES achieves a high degree of product purity.

Gingko biloba extracts have applications in preventive medicine

The main active ingredients extracted from gingko biloba are ginkgo flavone glycosides and terpene lactones. Clinical formulations typically standardize extracts into EGb 761, containing a 24% concentration of flavonoids and 6% terpenes.

The extract is applied as a protective agent for a range of diseases, from vascular disorders to neurodegenerative conditions.

Processing steps involved in ginkgo extract making

Which ginkgo extract technology do you need?

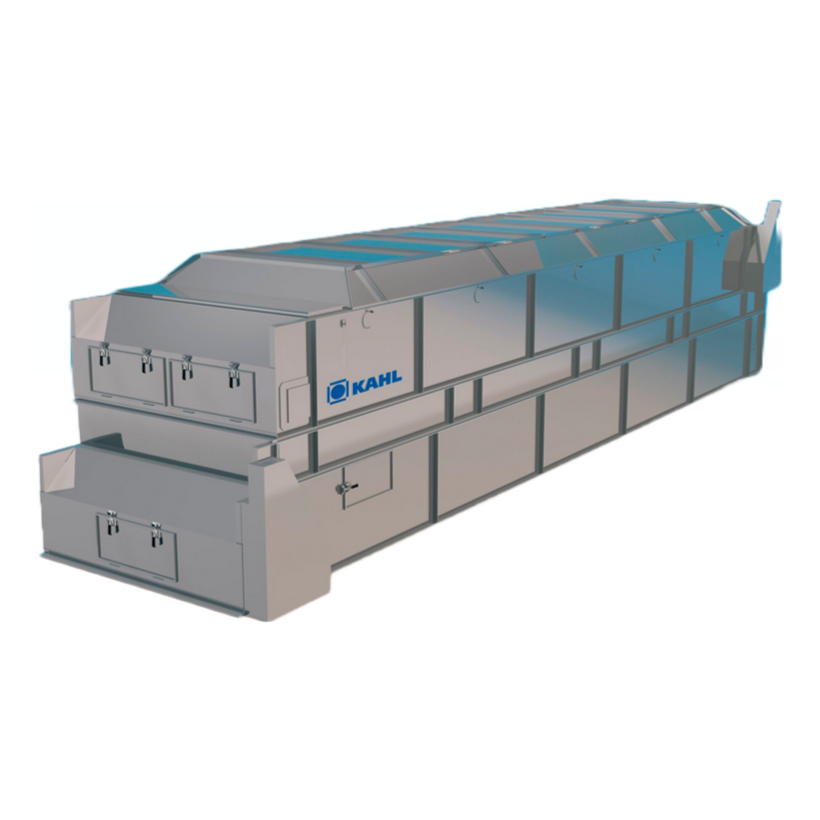

Vacuum belt dryer for fruit, vegetable and herbal extracts

Organic volatile compounds from fruits, vegetables and herbs ...

Benchtop peristaltic dispenser

When you fill vials and ampoules, high standards of hygiene are required to avoid the risk of...

Benchtop piston filling equipment for vials in trays

Vials are difficult to fill individually through manual methods due ...

Semi-automatic vial crimper

In a small production line, crimping vials manually can cause fatigue to your operator due to mu...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

Vacuum cabinet dryer for plant extracts and functional foods

Plant extracts are vital to functional food preparations. B...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

Evaporation plant for the recovery of extracts

Bespoke evaporation plants using the latest plate evaporation technology ca...

Continuous belt freeze dryer

Freeze drying is the most gentle and aroma protective method of drying, widely used in the coff...

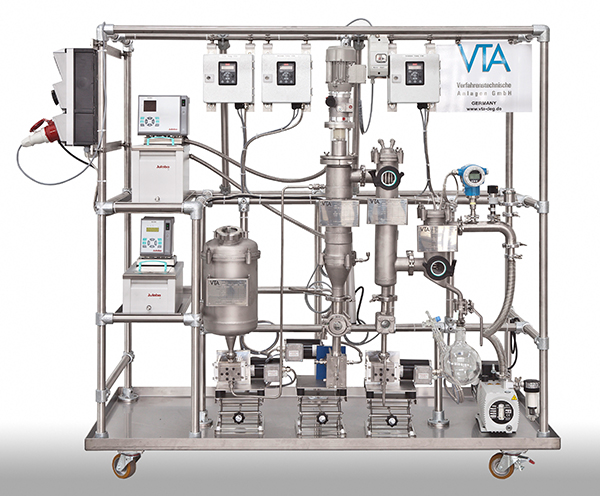

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

Laboratory short path distiller

Get to reliable conclusions for the separation of high-boiling and heat-sensitive products u...