Making Stock Cubes

Find innovative production technology for making stock cubes and connect directly with world-leading specialists

Stock cubes, also known as bouillon cubes or broth cubes, have been used in cooking for centuries. Think that, the first written version of a stock cube comes from Anne Blencowe’s recipe book from 1694. Made of dehydrated vegetables or meat stock, the bouillon cube production line consists of mixers, homogenizers, cube forming machines and packaging machines.

Tell us about your production challenge

How do stock cubes turn water into broth?

Stock cubes’ main ingredient is salt- it reduces the water activity, decreasing microbial growth, which is essential for product stability. Sugar is also added to bouillon cubes for flavor and to increase microbial stability.

Another ingredient added to stock cubes is monosodium glutamate (MSG), which enriches the savory flavor of the stock with only one-third of the amount of sodium. Bouillon cubes also contain fat, either from meat or palm or corn oil.

Other ingredients include meat and vegetable extracts, dehydrated vegetables, and various spices (turmeric, pepper, coriander). All of these ingredients are held together by agglomeration of the crystalline bonds after water evaporation from the mixture and by stabilizing agents like sulfites, citric acid and tert-Butylhydroquinone (TBHQ). The crystalline bonds become weaker when they interact with water, releasing the preserved flavors of the stock cube in the water and turning it into broth.

Bouillon cube production line for hard and soft cubes

There are two types of bouillon cubes: hard and soft. Soft bouillon cubes crumble easily and leave an oily residue on the skin, while hard cubes are compact and break into powder when squeezed. Changes can be made in the bouillon cube production line to facilitate the production of either type of bouillon cube.

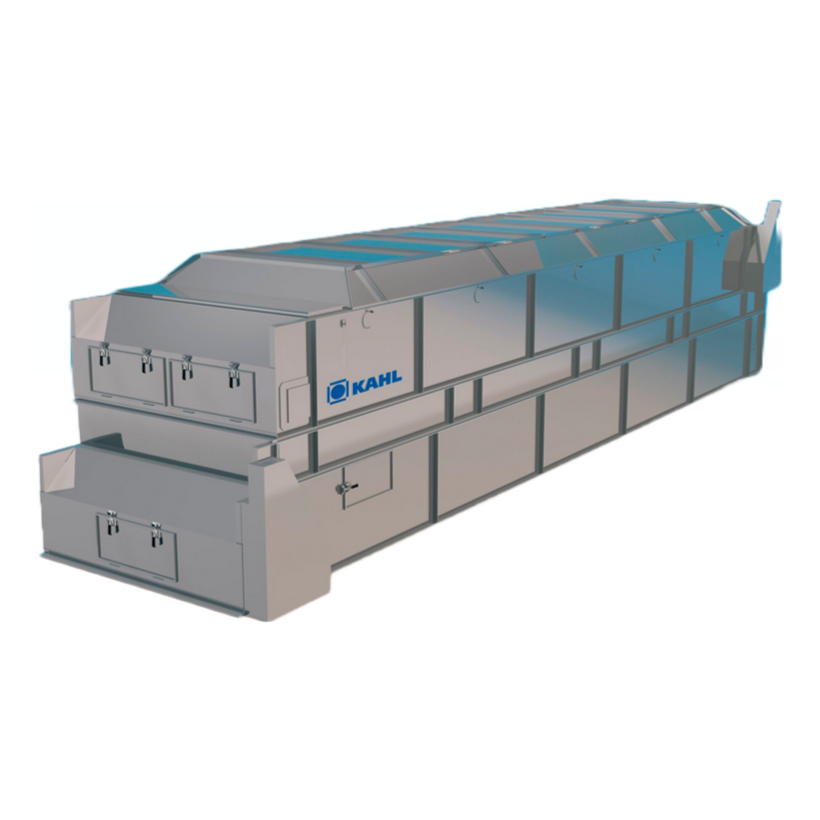

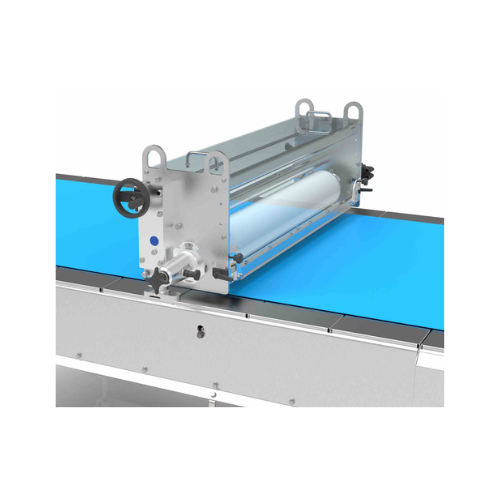

To produce a batch of hard cubes, the mixture of ingredients is compacted with high-pressure to create a pressed cube. Alternatively, a roller compactor can be used to both compress and shape the dried mixture. Pressed bouillon cubes have a hard texture since they allow for low-fat content.

Another way of producing stock cubes is with extrusion– the mixture is transferred into an extruder where it is heated, pressure treated, and shaped into tablets or cubes. Having a high-fat content, the pasty mass gives the cubes a soft texture, meaning that the stock cube can be easily crumbled.

Stock cube production process: pressing

The biggest challenge for manufacturers is the shape retention which is directly impacted by the fat added to the stock. The cubes crumble more easily if the fat added to the mixture is spray-cooled powdered fat. On the other hand, the stock cubes that contain melted fat are much firmer and do not crumble.

When the dehydration step is finished, the mixture is turned into fine powder with industrial grinders and that powder is then transferred to molds that shape it into cubes or tablets by applying pressure. To test the firmness of the tablet, additional pressure is applied to the tablet with a metal plate to test the product’s hardness or a cylinder probe that measures the amount of pressure necessary for the cube to crumble.

Packaging solutions and trends – let’s think outside the box

For as long as we can remember, stock cubes have always had the same shape and packaging; wrapped in plastic or metal foil and packaged into a carton. Nevertheless, users dislike the fact that the individually wrapped stock cubes can fall out of the carton; and it’s surprising to think that despite the criticism of packaging, no manufacturer has tried to create a new packaging format for so long.

However, some manufacturers have become increasingly creative with the shapes of stock cubes- the ‘cubes’ now come in different geometric shapes such as tablets, triangles, balls and cones. Some stock cubes, for example, can be packaged without individual wrapping due to a lower risk of fat staining. Manufacturers also started using wrappers made of metalized paper that significantly reduce the carbon footprint by eliminating plastic components.

Zero salt stock cubes

To reduce the amount of salt we consume, it has been replaced by a blend of various vegetables, herbs and spices like nutmeg, thyme, turmeric and rosemary.

Salt not only adds to the flavor of the broth but its crystals retain the cube’s shape, which makes zero-salt stock cubes tricky to produce. Food scientists finally managed to find a balance between the dry ingredients and fat that chemically bond and hold the cube’s structure together to replace salt and MSG in zero-salt cubes.

Vegetable stock cubes – vegan or not?

Vegetable stock cubes are vegan as long as they do not contain meat extracts or fat from animal sources. Moreover, vegetable stock cubes can contain gelatin which is not a vegan ingredient. Hence, consumers still have to refer to the ingredient list to be sure whether the product is vegan. Vegetable stock cubes certified vegan are made with non-hydrogenated palm oil and various vegetables, like garlic, onion, carrot and celery, on a separate bouillon cube production line. This ensures that no cross-contamination occurs during the production.

Processing steps involved in stock cubes making

Which stock cubes technology do you need?

Semi-automatic tray packing for soup cubes

Effortlessly package soup cubes into organized, stratified layers, optimizing y...

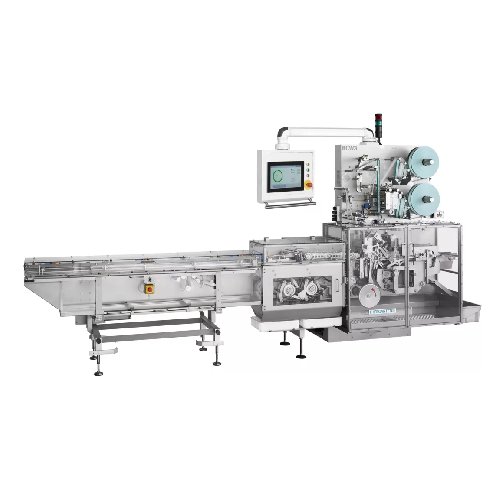

Soup cube dosing and wrapping system

Ideal for high-speed production, this system precisely doses and wraps soup cubes, enh...

Pressed soup cube bottom fold wrapper

Optimize your packaging line with high-speed wrapping machines designed for precision...

High-speed packaging machine for bouillon cubes

Streamline your production process with a machine designed to handle up to...

High-speed cartoning system for primary wrapped products

Optimize your packaging line with this high-speed cartoning syst...

Bouillon cube press machine for medium-range batches

The pressing stage during the production of bouillon cubes or tablet...

Endload cartoning machine

As demand for food production increases, so does that of packaging and sealing the product and mak...

High-speed cut & wrap fold machine

For large scale production of toffees, caramels and chewy candy products, speed of throu...

Case sealer

Automatic sealing of corrugated cases can speed up your production process. You can seal with tape or, in case you...

Laboratory extruder

Products can be extruded with a variety of shapes and characteristics by controlling the nozzle geometry ...