Making Glue

Find innovative production technology for making glue and connect directly with world-leading specialists

To make glue, you usually starting from gelatin, which is animal collagen. Glues help in the production of furniture, automobiles, clothing, paper, wood, art and craft, to name a few applications. The production of different glues depends on their industrial use. Different manufacturing processes and glue making equipment make it easier to create the many variations of this useful product.

Select your glue process

Tell us about your production challenge

Mixing base ingredients and additives with glue making equipment

Glue composition depends on the industry, and can be natural or synthetic. To produce natural glue, you use animal sources like collagen, or plant sources like dextrin, as a base ingredient. Animal glue comes from bone, fish, hide and skin. If you opt for synthetic glue, use cyanoacrylate esters to make superglue and add additives to get your final product.

It is essential to mix the ingredients well to achieve a homogenous mixture. Glue making equipment like a high shear lab mixer can help you achieve this. Since improper temperature ruins the quality of the product, always check the temperature and pressure of the glue making machine.

Glue made from animal and plant sources is mostly water-based and has different bonding conditions from the super glue. The latter bonds only when there is moisture on the surface when applying it.

Removing impurities from the glue liquid

To make the glue clear, it’s important to remove water and impurities from the resulting glue liquid. Heating helps to thicken the glue, and removing the impurities by adding alum and egg albumin allows the dirt to precipitate. You can use the decantation method to separate the clear glue from impurities. Quality control of glue products helps you determine if it meets company and consumer’s requirements. Also, test the peel strength of the product during quality control to help determine its bond strength.

Vegan options: can glue not use animal sources?

Glues that use animal sources as a base are common in the market because the raw materials are easily accessible. However, you can produce vegan-friendly glues with gum arabic extracted from acacia trees. Agar and algin from seaweed are also good options for vegans. There is a wide range of glues with different chemical compositions and bonding conditions. This is why you should determine which one works best for your process.

For example, white craft glue is water based glue suitable for paper and cloth. The yellow wood glue works best in the wood industry because of its rigid nature. It is advisable to use these glues in optimal environments such as surface condition and temperature. This helps enable optimum bond strength. Super glue, for instance, works best when there is moisture and you can use it for ceramics and leather. The glass and metal industry uses pressure sensitive adhesives (PSA) for their projects. To build competitive intelligence, it is important to keep up with market trends. The demand for industrial adhesives is increasing in Europe and the US and there will be a significant revenue increase by the end of 2030.

Sustainable alternatives to reduce glue’s environmental impact

When producing glue, consider the biodegradability of the disposed product. If not correctly disposed of, it may end up contaminating groundwater and soil. To make the glue production process eco-friendly, you should consider using ingredients that are biodegradable and renewable in your gluing machine. You can use materials like beeswax and agar because they are not composed of crude oil. Production of PVA glue releases toxic fumes, but you can use starch and dextrin as a substitute to reduce their impact.

Processing steps involved in glue making

Which glue technology do you need?

Precision 2k dispenser for automated systems

Achieve precise mixing and dispensing of two-component materials with minimal...

Automated precision spraying dispenser for high viscosity materials

Achieve precise spraying and consistent coating res...

Compact Mixing Plant for Paints and Coatings

A smooth finish in paints and coatings depends on the grade of dispersal duri...

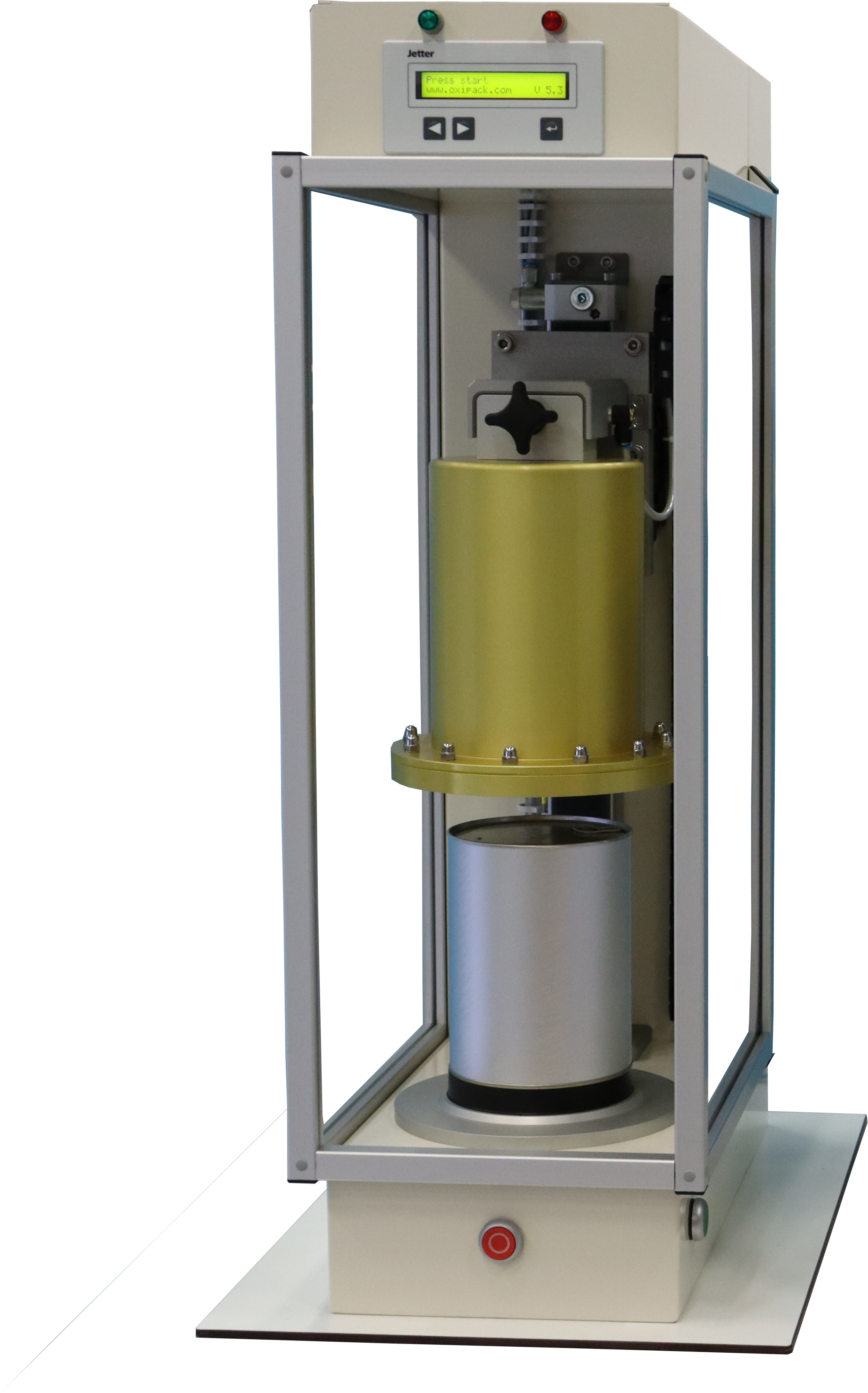

Can leak tester

Every canned pet food producer knows that their product should avoid the growth of microorganisms that could s...

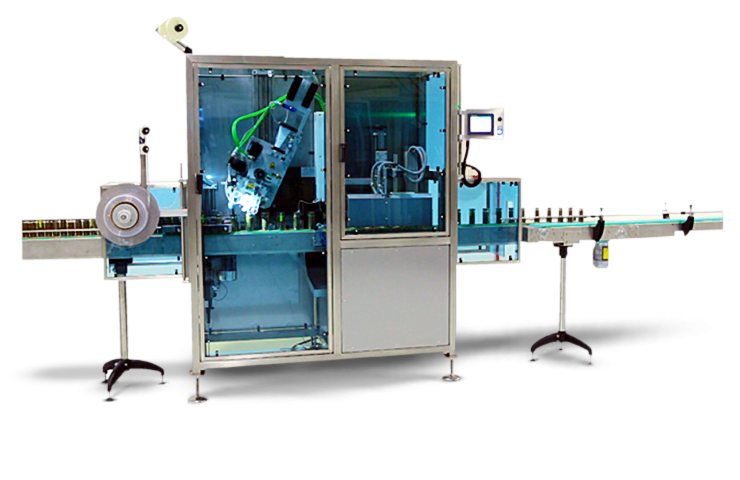

Automatic can sealer

If you need to cap paint, glues, and solvents containers and are currently manually placing the lids, yo...

Shrink sleeve applicator - 400 per minute

Flexible medium to high speed application of shrink sleeveing to containers is u...

Compact shrink sleeve applicator

Adding tamper prevention to product packaging can be expensive and difficult to set up. Thi...

Electric shrink tunnel solution

Adapting shrink sleeve heating tunnels for different applications can be a lengthy and expen...

Laboratory size auto-steam shrink system

When managing sleeving projects, fast prototyping and testing can gain massive com...

Shrink sleeve applicator - 600 per minute

Several industries require the flexible addition of shrink sleeves to containers...

In-line tamper evident applicator head

Integrating tamper protection equipment into an existing production line means addit...

Shrink sleeve applicator - 800 per minute

High speed, in-line shrink sleeving systems require dual head capability with hi...

Advanced auto-steam shrink system

Design and development of shrink sleeves could be made much easier if small batches of sa...

Premium steam tunnel for sleeve application

Maximum flexibility in terms of pressure, temperature and ramp setting and adj...

Shrink tunnel for applying sleeves to different containers

Maximum flexibility is required when setting pressure and dir...

Tamper-evident sleeve applicator for caps

Reliability, continuity and changeover time are key success factors for tamper-e...