Making Eyeshadow

Find innovative production technology for making eyeshadow and connect directly with world-leading specialists

If you want to make your eyes more attractive and add depth and dimension to them, applying color to your lids is what it takes. Eyeshadow serves this purpose and is available in powder, liquid, pencil and mousse form. In an eyeshadow production line, compact eyeshadows are produced by grinding and mixing powders before compaction, whereas molded eyeshadows are made from waxes and oils mixed with pigments and then poured into molds. Instead, by mixing oils, gelling agents, elastomers, and pigments you can make a mousse eyeshadow.

Select your eyeshadow process

Tell us about your production challenge

What is the role of ingredients in an eyeshadow production line?

Base fillers, binders, slip agents, and preservatives are the core ingredients to create eyeshadow. Base fillers make up around 25% (in eyeshadow powders) to 30% (in creamy eyeshadow) of the eyeshadow and give the product its structure and shades of color. Mica, talc, and kaolin are some examples of base fillers. Binders can come in dry form such as zinc and magnesium powders or in liquid form such as silicone, paraffin wax, and mineral oil. Their job is to keep the eyeshadow attached to the skin. Silica, boron nitride or bismuth oxychloride are types of slip agents. These allow the eyeshadow to be applied easily onto the skin. Lastly, preservatives like glycol and tocopherol keep the products bacteria-free and help prolong their shelf life.

Not everything that glitters is gold – environmentally-friendly glitter alternatives

Who doesn’t want to shine bright like a diamond? Glitters in eyeshadows, add highlights to the colors and gives off that glamorous look that everyone is looking for. But actually, these small shiny flakes can be detrimental to the environment and are threatening marine life due to their composition.

Because of their size, it is easy for them to pass through filters in waterways and move into oceans after washing them off. Dr. Trisia Farrelly from Massey University has called for a ban on plastic-based glitter. Glitter is microplastic since it is a combination of aluminum and plastic, so it takes one thousand years to biodegrade.

There are other materials aside from microplastics that can make glitters more environment-friendly and sustainable. Mica is a great alternative to plastic-based glitter. This naturally occurring mineral gives off a shine or shimmer effect. Cellulose coming from plant extract, especially eucalyptus is another alternative to microplastic. That’s what bio-glitter is made of. Although it is quite expensive and because of that, not many manufacturers are using it, glass can also be a green alternative to regular glitter.

Regulations for chemical ingredients in cosmetics

Some ingredients that are used in eyeshadows are prohibited by the FDA for reasons that may cause health problems. Ingredients like carbon black have been linked to causing cancer and organ system toxicity. In the EU, regulations are more stringent compared to the US. The EU law bans 1,328 chemicals from cosmetics including parabens that are commonly used as preservatives but are known to be endocrine disruptors that are linked to reproductive toxicity.

They also prohibit the oil glands that line the eyelid from secreting oil. The EU also requires safety assessments for cosmetics before releasing them to the market, mandatory registration of cosmetic products, and government authorization for using nanomaterials and prohibits animal testing.

Making an eyeshadow cake using an eyeshadow press machine

After grinding and mixing all the ingredients, you can pour the powdered product into metal containers that are gradually pressed by a mechanical eyeshadow press machine to form a cake mixture. The amount of pressure should match the size of the container for the product to be of good quality. A well-pressed cake mixture will not easily break inside the container when dropped during transportation and will not flake or glaze when used. Manufacturers also use drop tester machines to test the compaction quality of the pressed powder. Producers can also give a custom look to the cake mixture through stamping or embossing names or logos before sealing it. If it’s not the case, they can simply seal the container right away and label it on the containers.

Processing steps involved in eyeshadow making

Which eyeshadow technology do you need?

Drying solution for cosmetic slurries

Streamline the drying process of cosmetic slurries with precision control to achieve ...

Flexible R&D wet agitator mill for cosmetics

Using nanoparticles in cosmetics requires precise control over material break...

Blending tank for cosmetic powders

The production of high-quality cosmetics powders requires perfect mixing and dispersal o...

Manual cosmetic powder press

The design, manufacture and testing of new cosmetic powder products require a small-scale press...

Makeup blusher compacting machine

When producing high-quality compressed powder cosmetics, control of the pressing process ...

Vibrating screen for cosmetic powders

Dense or viscous compounds can be difficult to prepare for use in cosmetic products. ...

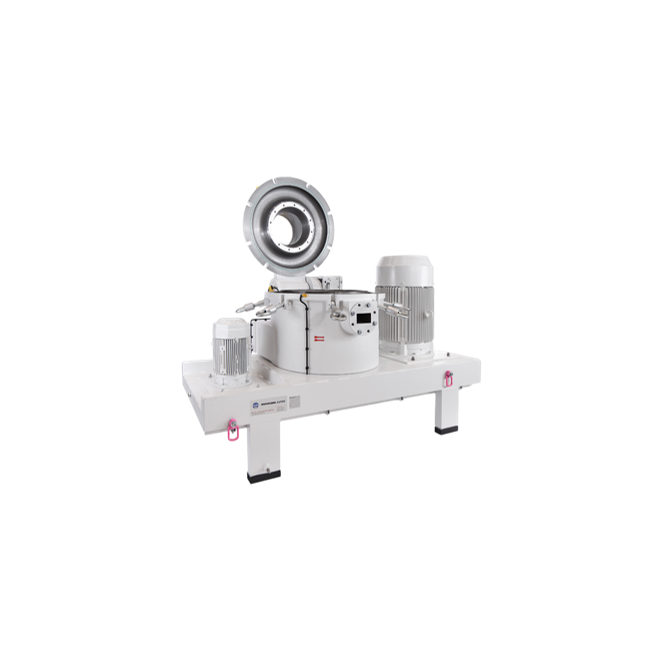

Cosmetic powder pressing machine

For the medium and large-scale production of compressed powder cosmetics, a fully-automatic...

R&D V-type powder blender

Many pharmaceutical processes rely on the complete blending and homogenizing of different powdered...

Compact powder pressing machine

Pressed powder products are extremely popular in cosmetics, but their production has challen...