Making Dried Oregano

Find innovative production technology for making dried oregano and connect directly with world-leading specialists

In classical Greek, oregano means “mountain adornment,” Indeed, the desiccated herb embellishes many age-old recipes. Traditionally, the fragrant leaves were collected and left to air dry in a shaded area. But that method leaves the plants exposed to open field risks such as pest attacks. Today, dried oregano processing equipment creates a hygienic environment that allows the plant to release moisture faster while retaining more natural compounds.

Select your dried oregano process

Tell us about your production challenge

Cut the stems into uniform lengths for easier processing

The oregano plant is harvested during the flowering stage, and fresh material is processed quickly to preserve as many biochemicals as possible.

Pass the stalks through a vibrating sieve to clean the plants from stones or soil. Then wash away sediments, insects, or other plant material with water. Your oregano stems are now ready to be chopped into equal lengths.

Select dried oregano processing equipment based on temperature control

One of the main challenges of dried oregano processing equipment is to retain the herb’s essential oils. High temperatures make the drying process faster but degrade the delicate plant.

Microwave technology raises the temperature uniformly without subjecting the product to long heating periods. Continuous microwave-convective air drying is the fastest technique, but it results in poor essential oil retention. Intermittent microwave-convective air drying at a 5.0 pulse ratio keeps the same essential oil content as air drying at a fraction of the time.

Cryogenic grinding preserves volatile oils during milling

Particle size distribution is critical to herbs and spices in general. Once dried, oregano is milled to obtain an even particle reduction. But grinding equipment such as ball mills or hammer mills ramps up temperatures during operation, allowing volatile oils to escape from the material.

Cryogrinding techniques protect the volatile compound content and lock in the natural color and aroma of the plant. In addition, milling with chilled air or water circulation produces a uniform particle size distribution and prevents the clogging of the equipment.

Use microwave technology to extract natural compounds from oregano

Oregano is rich in rosmarinic acid, a polyphenol with anti-inflammatory properties. This compound is used to treat several ailments, from indigestion to asthma.

Rosmarinic acid has traditionally been extracted from oregano through maceration, but microwave-assisted extraction provides a more environmentally sustainable alternative. The technique requires a shorter energy discharge to heat the plant material. This means that the unstable biochemicals in the oregano leaves endure less heat pressure.

Processing steps involved in dried oregano making

Which dried oregano technology do you need?

Flat-belt slicer for fruits and vegetables

Optimize your slicing process with a solution that delivers precision cuts whil...

Food dehydrator with stainless steel trays

Achieve optimal dehydration with precise temperature control and efficient dual...

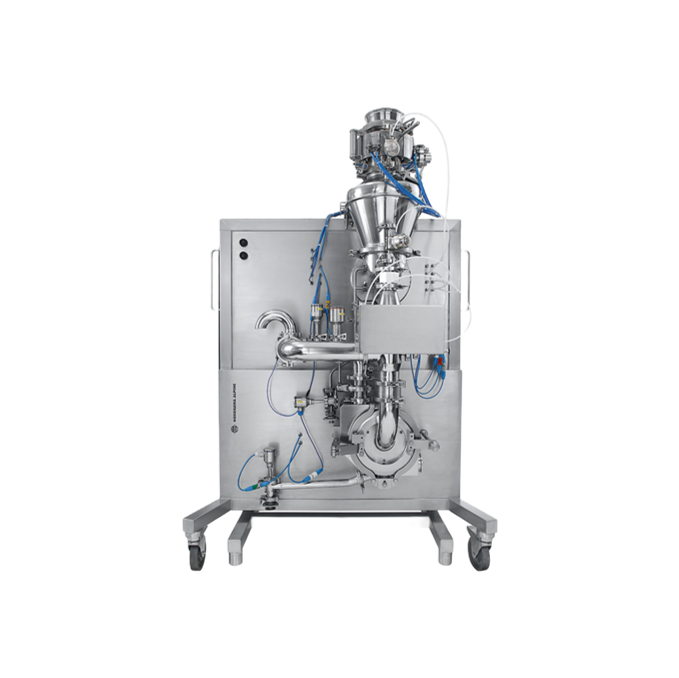

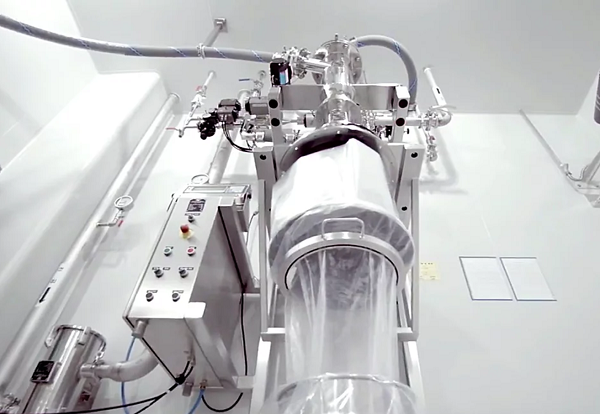

Drum filling system

Pharmaceutical and chemical products may be toxic or prone to contamination from environmental exposure. ...

Industrial drying cabinet

The production of high-quality biltong and similar dried meat products can pose problems with main...

Continuous dryer machine

Traditional drying methods in the pet food, aquafeed, and extruded food industry can be the most ene...

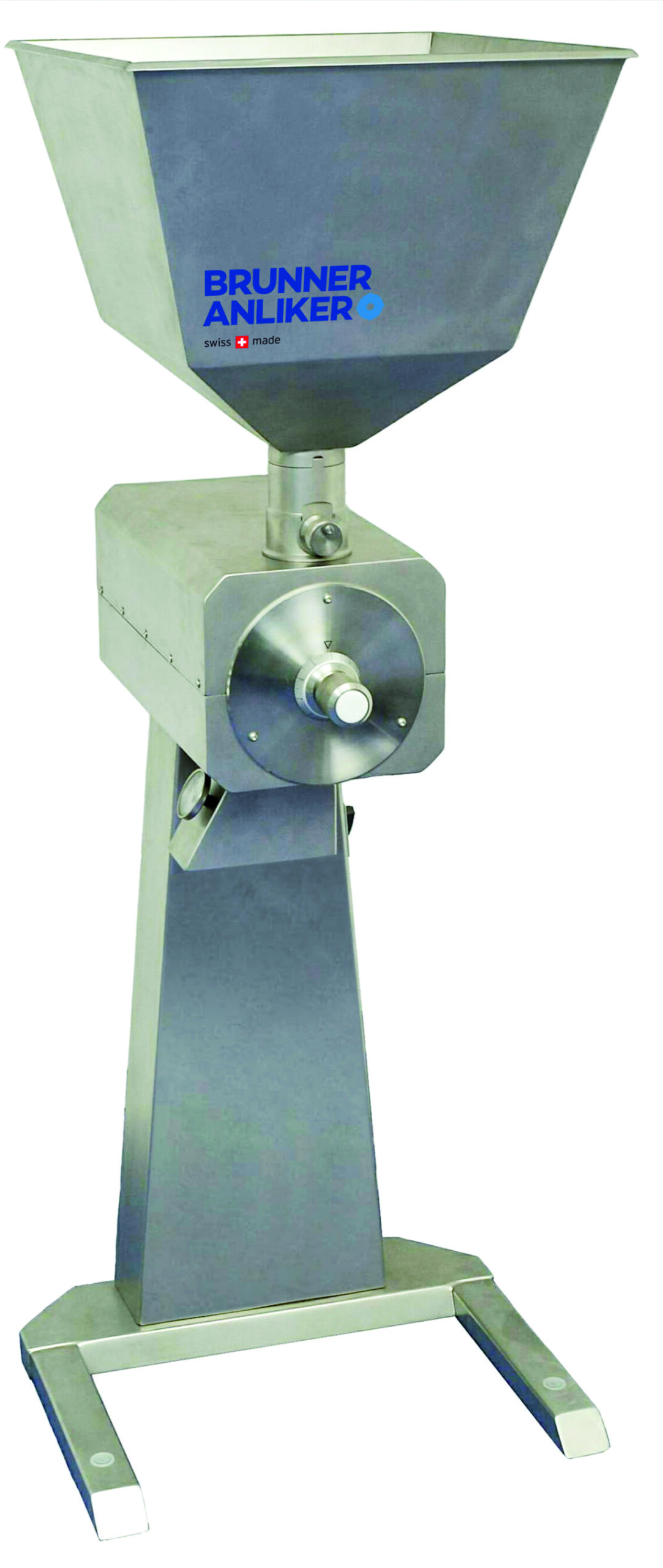

Grinder for spices and coffee

Gentle grinding of coffee down to all grades from coarse to fine requires high precision proce...

Entry level HFFS Machine for flat sachets

Traditional horizontal form fill and seal sachet machines for lower volume lines...

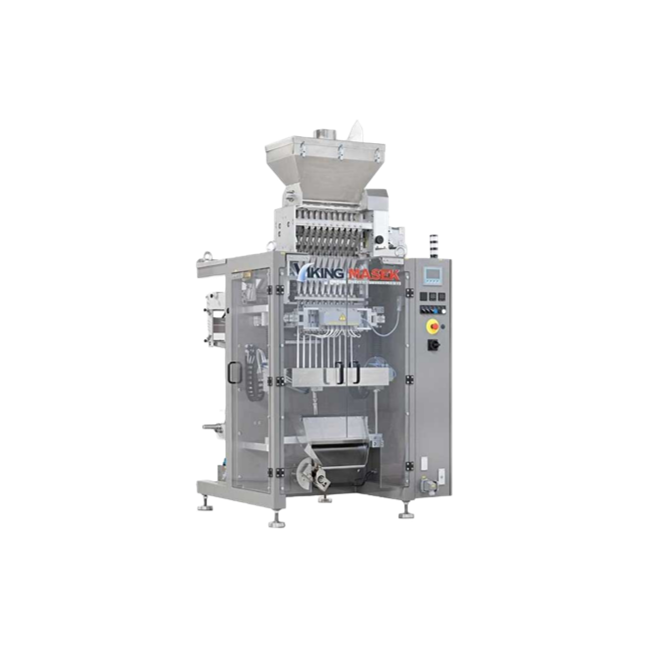

High-Speed Pouch Packaging Machine

For large scale production of powders and liquids in a wide range of industry sectors, a...

Continuous fluid bed dryer

In a Fluid Bed, a product or solid is made fluid by an upward moving flow of gas. The mechanical ...

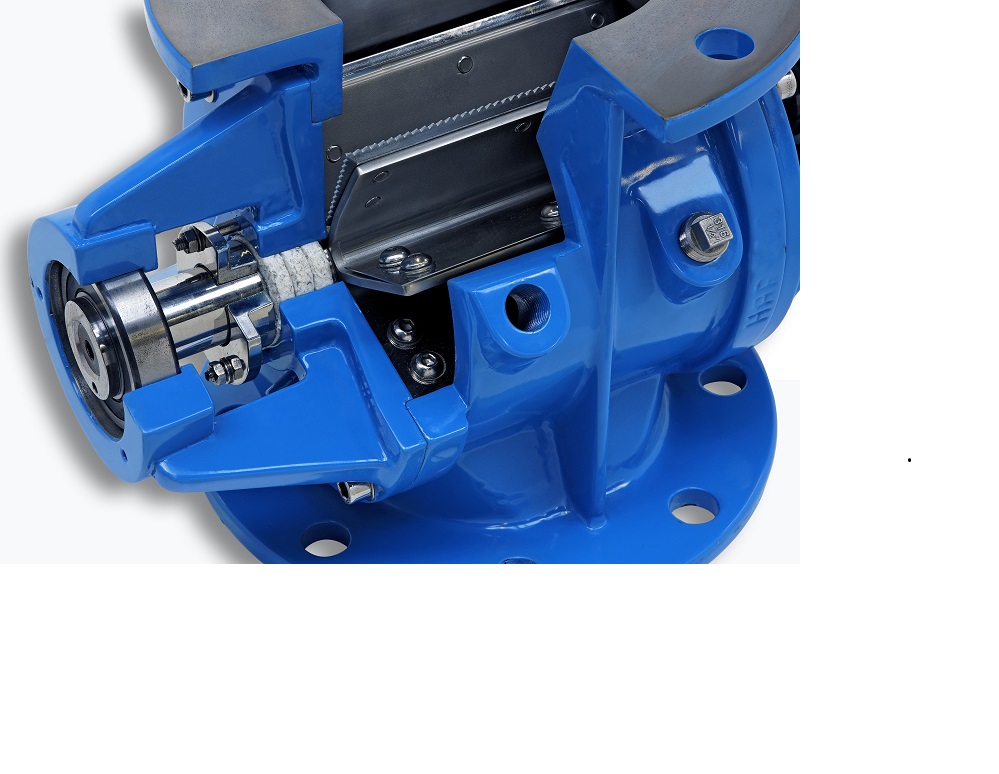

Heavy duty rotary valve

Handling powdered and granulated materials in pneumatic conveying systems requires consistent, safe v...

Dual channel plug diverter valve

Short switching times are often required when diverting or combining powder or granular sol...

Hygienic belt dryer

A belt dryer typically applies the product through an infeed chamber onto a perforated horizontal belt, w...

Air dehumidifier for bulk products

When your product or process is sensitive to humidity, using an air dehumidifier may res...