Find technology for processing medical gummies

Find innovative production technology for making medical gummies and connect directly with world-leading specialists

Medical gummies are a great alternative to traditional tablets while having to take medicine since they are easy to consume and can taste and look more appetizing. The pharmacological properties of the active ingredients in medical gummies render them particularly susceptible to environmental factors, which means you have to pay a lot of attention to detail when producing them. Therefore you have to follow rigorous regulations to ensure consistency, potency, and safety in every batch.

Stories about medical gummies

Tell us about your production challenge

The key lays within the ingredients

The active pharmaceutical ingredients (APIs) are responsible for the therapeutic effects of the gummies, but you must also add other components such as sweeteners, flavors, and colors. Ingredients like acetaminophen, ibuprofen, or aspirin may be used in gummies designed to provide relief from pain, fever, or inflammation. Use herbal extracts, amino acids, probiotics, or omega-3 fatty acids, in gummies to address specific nutritional needs or promote well-being. Medical gummies can also provide sleep or allergy relief.

Choose the right method to add APIs into your gummy mixture

First you can mix the API is directly into the gummy formulation during the manufacturing process. You must thoroughly blend the API with other ingredients such as gelatin, sweeteners, flavors, and colors to create a homogeneous mixture. Then you have to pour the gummy mixture into molds and allow it to set.

APIs can be encapsulated within the center of the gummy shell using specialized equipment. You must inject or deposit a liquid or gel formulation of the API into the center of each gummy before it completely sets. The gummy shell provides protection for the API and helps control its release. Other methods also include topical application, layering or coating the gummies with APIs.

Not just a gummy, but medicine

Although industrially producing medical gummies is quite similar to the production of regular gummies, they are operated under different regulations and guidelines. The first differences appear already in the gummy formulation, while with traditional gummies you focus on achieving desirable taste, texture, and appearance. But with medical gummies, you must deliver precise doses of medication or supplements.

Depending on your method of adding API, the gummy-making process could vary, but inherently it is the same: mixing, cooking, depositing, curing, conditioning, finalizing, and packing.

Which medical gummies technology do you need?

Automatic gummy production equipment

Achieve consistent gummy quality with high-speed depositor technology ideal for small ...

Packaging system for gummy products

Optimize your gummy production with a flexible packaging system that safeguards product...

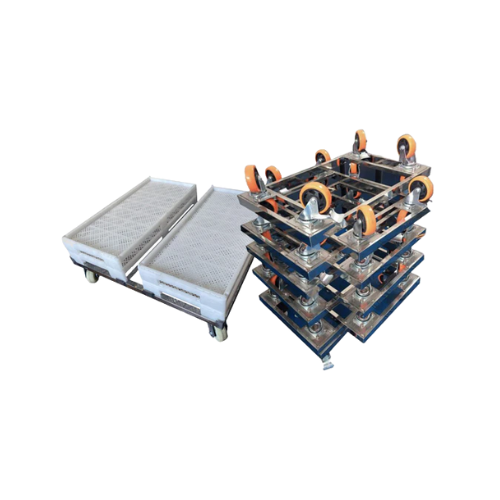

Drying trays for gummy candy production

Ensure proper drying and setting of your gummy candies and gelatin-based products w...

Small-scale gummy candy depositor

Optimize your confectionery production with this manual depositing machine, capable of pr...

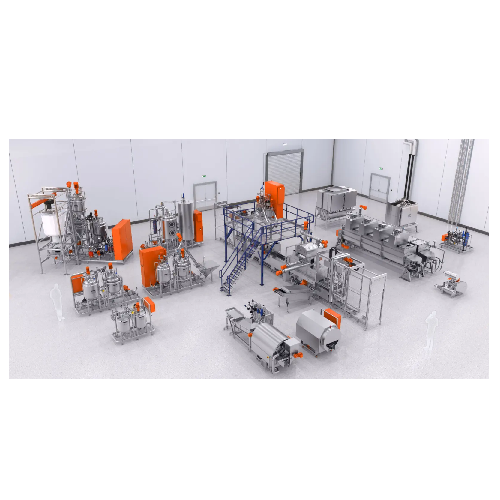

Automatic production line for gummies and nutraceuticals

Maximize the versatility and efficiency of your production space...

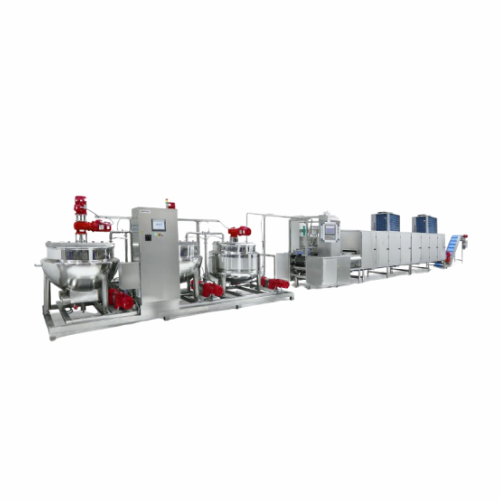

Mid-capacity gummy and jelly production system

Ideal for manufacturers aiming to integrate functional ingredients into gum...

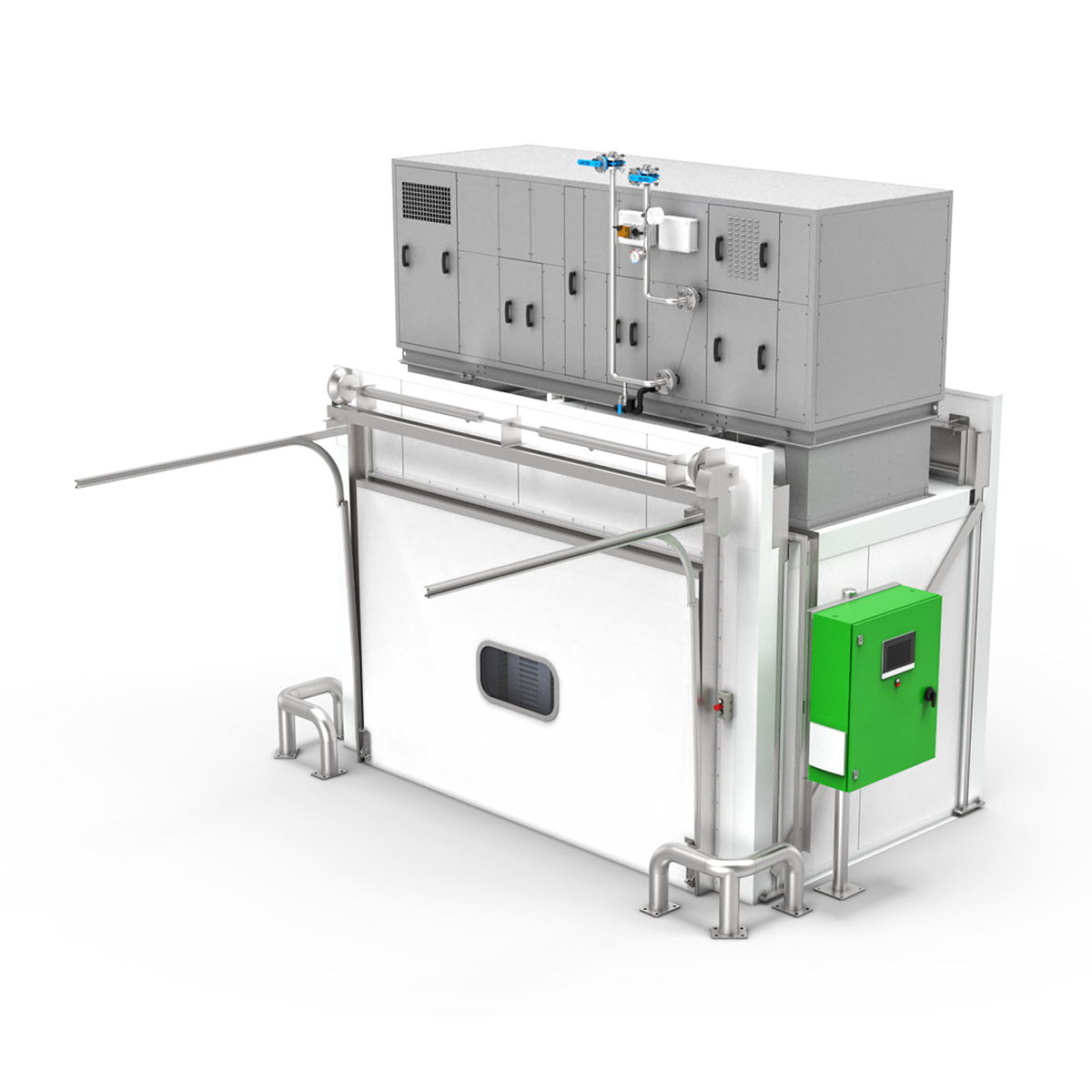

Entry-level conditioning system for drying nutraceutical gummies

The drying process demands specific environmental condi...

Entry-level cooking system for vitamin and CBD gummies

Producing functional gummies or jellies with functional ingredient...

High Output Industrial Production Line for Gummies and Jellies

Mainstream technology for the preparation of gummies and ...

Cooker for gums and jellies

Prepare your ingredients for use in gummy and jelly products. This is a static cooking system de...