Making Eucalyptus Oil

Find innovative production technology for making eucalyptus oil and connect directly with world-leading specialists

Koala bears diet exclusively on eucalyptus leaves. But the large concentration of cineole in the tree keeps most other predators at bay. Humans, though, discovered ways to extract the substance and use it as a remedy against inflammations and other diseases. The eucalyptus oil production process keeps evolving to maximize yields, ensuring enough eucalyptus forests for koalas.

Select your eucalyptus oil process

Tell us about your production challenge

Use steam extraction to prevent damaging the organic material

Eucalyptus oil is temperature sensitive and could begin to decompose if heated to its boiling point of around 200°C. But steam distillation releases volatile compounds at 100°C, retaining the natural properties of the chemicals.

Resize the fresh plant material into uniform pieces and place them in the still chamber of the distiller. The oils charge the vapor fed from a steam generation machine and rise to the top of the still. Pass the gaseous mixture through a condenser to return it to the liquid state. Collect the mixture in a separatory funnel and pour the newly processed eucalyptus oil.

Stir the distillation waters in the eucalyptus oil production process

One of the earliest extraction methods of eucalyptus oil is water distillation. But the technique stood the test of time with advances in distillation technology. Solvent stirring is a significant development in this area.

Immerse the washed leaves in water and bring the solution to a boil at 100 °C to release the compounds. Agitating the solvent with a stirring speed of 900 rpm improves eddy dispersion and facilitates the distribution of volatiles.

Improve hydro-distillation efficiency with microwave-assisted technology

An adaptation of the hydro-distillation method is microwave-assisted heating. Using microwave technology to heat the water reduces the volume of solvent required and the time to reach boiling point.

Moreover, microwave power greatly impacts the eucalyptus oil production process. The extraction technology consumes lower energy and emits less CO2 into the atmosphere.

Add a co-solvent to maximize the return from supercritical fluid extraction

The volatile fraction typically makes up 90% of the compounds in essential oil. Supercritical fluid extraction applies pressure and heat to release this substance from the plant matrix.

Once heated to above its critical point, the fluid diffuses through the plant material like a gas and dissolves the compounds. Carbon dioxide is commonly applied as a supercritical fluid for extraction, but it can be blended with a co-solvent like ethanol or methanol to add pressure and increase yield.

Processing steps involved in eucalyptus oil making

Which eucalyptus oil technology do you need?

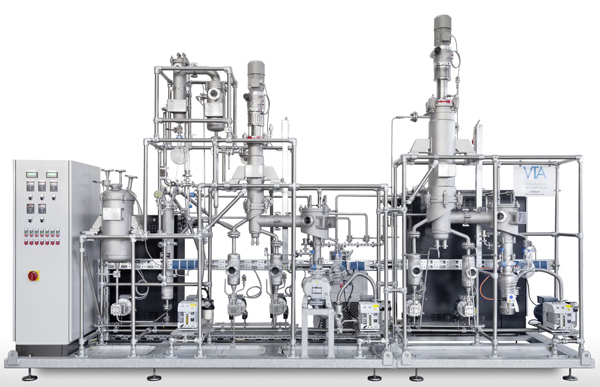

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

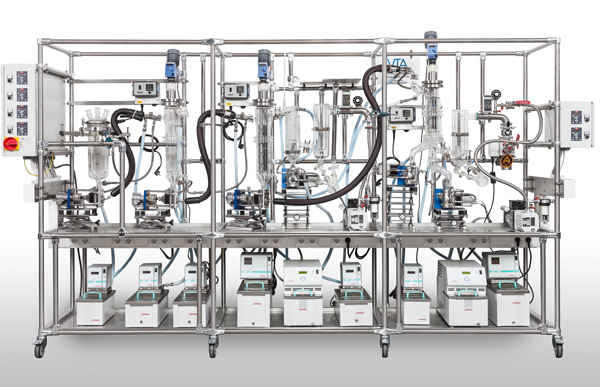

Pilot extraction plant for natural ingredients

Before purchasing a full-scale extraction plant you need to exactly determi...

Pilot short path distiller

Generate scalable data and results during the pilot tests with short path distillation, distill o...

Laboratory multi-stage distiller

A laboratory multi-stage distillers that combines the wiped film and short path distillatio...

Laboratory wiped film distiller

Reach reliable conclusions testing the distillation of high-boiling or highly viscous materi...

Laboratory short path distiller

Get to reliable conclusions for the separation of high-boiling and heat-sensitive products u...

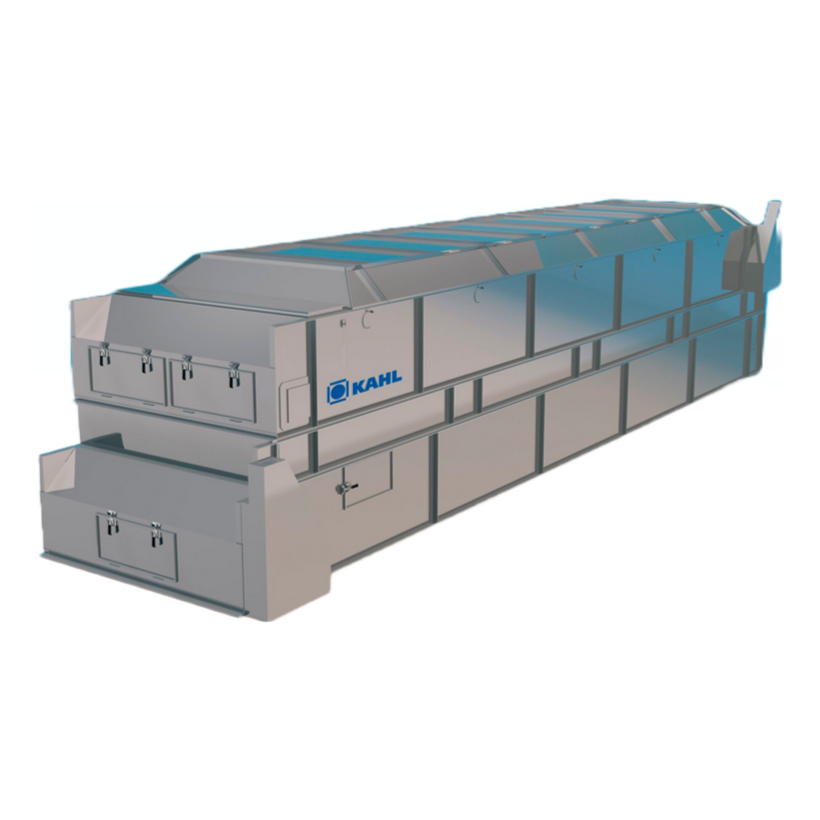

Horizontal thin film evaporators

Horizontal thin film evaporators can increase the residence time of the product and achieve...