Coffee blends

Find innovative production technology for making coffee blends and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Which coffee blends technology do you need?

Sample roaster for testing coffee blends

Ideal for coffee innovators, this bench-top roaster enables precise control over t...

Tangential coffee roaster for diverse roasting profiles

Achieve unparalleled precision and flexibility in coffee roasting...

Green coffee preheating system

Optimize your coffee roasting process by utilizing waste heat for preheating, reducing energy...

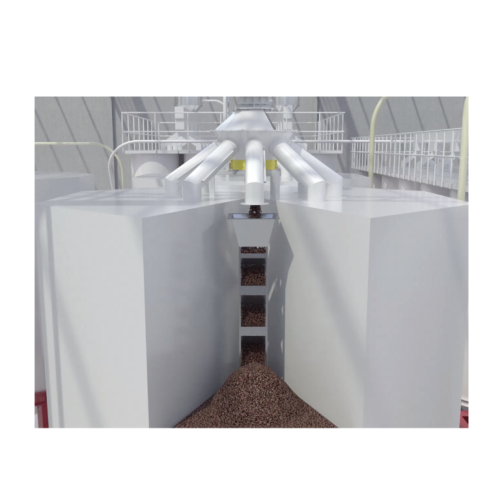

Roasted coffee storage solutions

Ensure the highest integrity of your coffee beans with advanced storage and handling system...

Mid-sized coffee roaster for specialty coffee shops

Optimize your coffee roasting process with precision control and vers...

Green coffee conveyor for efficient coffee roasting operations

Effortlessly streamline your roasting process by automati...

Mixer for blending coffee beans

Achieve precise and consistent coffee blends with a versatile mixer designed for smooth inte...

Sample roaster for coffee beans testing and profiling

Optimize your coffee roasting process with a versatile sample roast...

Industrial coffee roaster for large-scale production

Designed for coffee producers aiming to enhance their roasting capab...

Industrial coffee roaster

Achieve optimal coffee flavor with precise roasting control and energy efficiency, perfect for pus...

Industrial stir fryer for food production

Maximize cooking efficiency with a multi-function stir fryer that excels in cont...

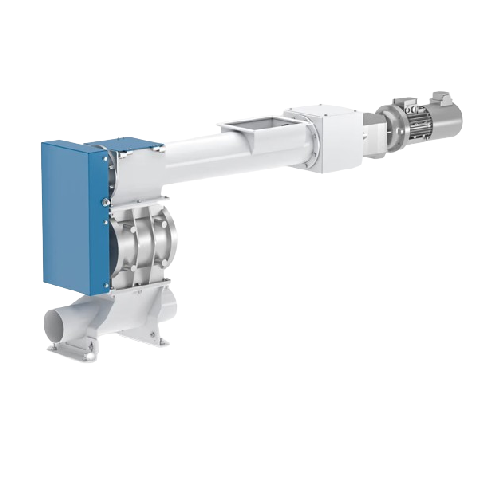

Continuous raw material distribution screw doser

Optimize your material flow with a screw doser designed for precise and c...

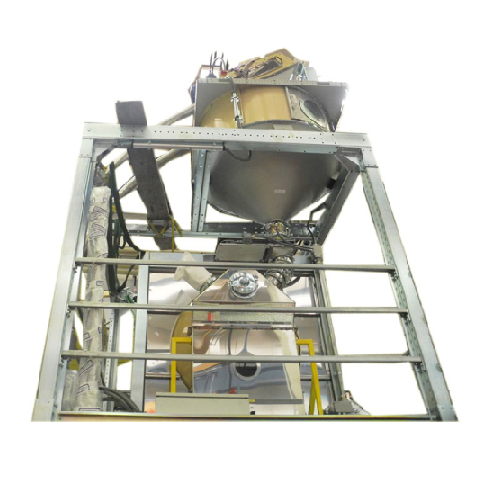

Bag rip-and-tip dump stations for bag emptying

Efficiently manage bag emptying operations with advanced dust containment a...

Blender for whole bean roasted coffee

Achieve precise coffee blend consistency and protect delicate roasted beans with an a...

Rotating sieve for roasted coffee

Optimize your coffee production with a rotating sieve specifically designed to handle del...

Automated coffee bean roaster

Optimize your coffee roasting with precision control, ensuring consistent quality in every bat...