Making Brewers Grain

Find innovative production technology for making brewers grain and connect directly with world-leading specialists

Brewers' grain, also known as brewers' spent grain or BSG, is the residue of malt and beer production. This brewing by-product is sometimes wasted causing an important environmental impact, nevertheless, with the circular economy in mind, brewers' grain processing can turn waste into value mainly for the feed and food industry, tackling some of the sustainable development goals (SDGs).

Technology picks for brewers grain

Dewatering solution for spent grain

Achieve efficient moisture reduction in spent grains with this continuous mechanical sc...

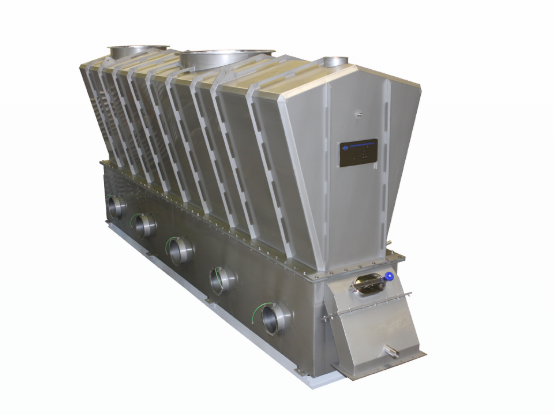

Turbo separator for Ddg agglomeration

Efficiently eliminate clumping and improve flow in your distillation process, ensurin...

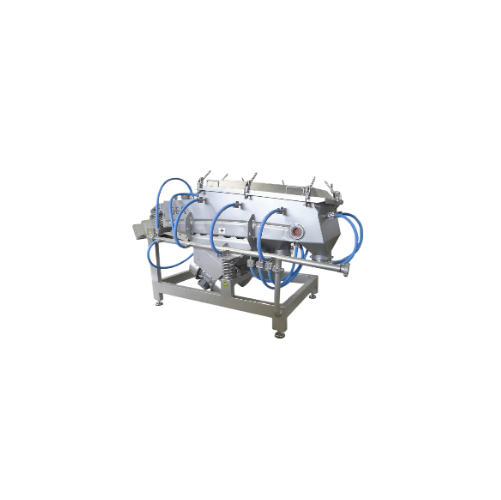

Continuous mash filtration system for breweries

Optimize your production line with continuous mash filtration that revolut...

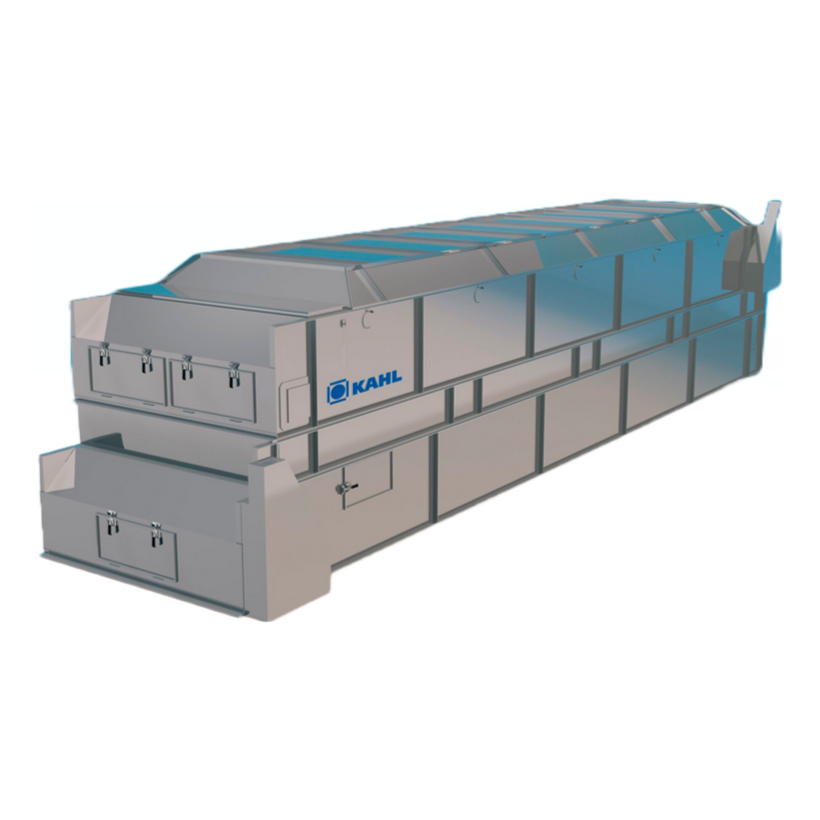

Energy efficient steam dryer for feed products

Traditional drying technologies with low investment cost, such as hot air d...

Tell us about your production challenge

The brewing industry generates 20kg of wet brewers’ grain per 100L

From the by-products of the brewing industry, brewers spent grain constitutes around 85% of the total, followed by approximately 13% of spent yeast. To get a better picture of the actual brewers grain volume, just make the calculation; when you produce 100 liters of beer, you get 20 Kg of wet BSG, then compare it to the global production of beers that in 2021 was 1.86 billion hectoliters, according to the statista.

That important volume of spent grain could create environmental degradation. Fortunately, the added value from brewers grain processing makes it a good raw material for the feed and food industry. But a small part of this by-product is still disposed of in the landfill.

Don't delay the preservation in brewers grain processing

Spent grains come out of the brewing process as wet residue. The high content of water makes the grains vulnerable to microbial growth and fast deterioration. But they are rich in protein, fiber, and sugar. Thus, it is importance to consume the wet product immediately or initiate the preservation process as quickly as possible. Some brewers sell or give away their spent grains just after processing when still wet. Its transportation can be costly and polluting, but it is expensive and difficult to preserve it on site, especially if you don’t have the space in your facility. The challenge is to find an industrial symbiosis to reduce emissions and waste by valorizing spent grains.

You can preserve the brewers’ grains by solar drying, oven drying, or freeze drying. Two of the brewers grain equipment most commonly used are rotary drum dryers and continuous fluid bed dryers. Drying the grains will reduce moisture from 80% to less than 10%, then you will obtain a brewers grain meal that can be converted into flour. There are also other physical methods including steam drying and freezing, as well as chemical and biological methods.

Brewers spent grain valorization upcycles the value chain

One of the objectives of the circular economy is to upcycle the value chain, in this case adding value to spent grains to use them as raw material for many products. For this reason, the brewery industry is finding synergies with other industries, innovation hubs, and other actors, to find solutions to meet the sustainable development goals. This way, brewers avoid dropping the residues into landfills, creating a circular bioeconomy around the spent grains.

Using spent grains for animal feed, food and fertilizers are the most common way of contributing to the SDGs. But there are also innovative applications such as new materials and compounds in the biotechnology industry, as well as bioenergy which includes biogas, biofuel, ethanol and others, that can be used for the brewing processes.

Processing steps involved in brewers grain making

Which brewers grain technology do you need?

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Industrial sifters for beverage processing

Optimize your beverage production with precisely engineered sifters that ensure...

Industrial rotary dryer for high moisture content materials

Achieve consistent drying performance with industrial rotary...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

Spent grain conveyor for breweries

Optimize brewery efficiency by transporting wet spent grains effortlessly and securely f...

Wet spent grains pre-dewatering system

Optimize your brewery operations with a dewatering system that efficiently reduces m...

Dewatering solution for spent grain

Achieve efficient moisture reduction in spent grains with this continuous mechanical sc...

Energy efficient steam dryer for feed products

Traditional drying technologies with low investment cost, such as hot air d...

Evaporator for heat sensitive products

The removal of solvents when making products in industries like food, cosmetics, pha...

Silo extraction system

Materials without natural flowing properties are difficult to unload, even with the assistance of grav...

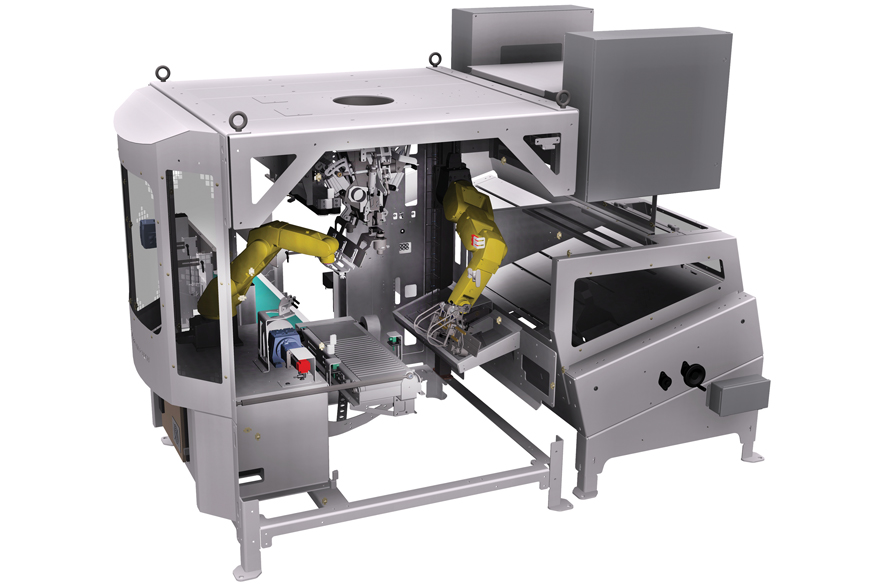

Bagger with rotary jaw drive actuation

If you are looking for a compact packing machine that fits into tight space and tigh...

Pelleting press for feed and petfood

The production of agricultural feed and pet food products requires machines and plants...

Belt filter press

When a saturated slurry or sludge must be dehydrated in a continuous process municipal waste water treatmen...

Versatile open-mouth bagger

If you want highly precise bagger for bagging multiple bag materials, here you go. This versatil...