Making Corn Seeds

Find innovative production technology for making corn seeds and connect directly with world-leading specialists

The average corn cob has 800 kernels, but each of those comes from one tiny grain. The quality of corn farming rests on the conditions of foundation lots. And these depend on the integrity of the process. Corn seed processing equipment prepares the grains so they can grow into multiple products ranging from food to energy to cosmetics.

Tell us about your production challenge

Apply gentle drying to avoid harming the maize seed

Harvested corn contains about 25% moisture content, a risk to the seed quality. Water incubates microorganisms that spoil the seeds.

But the crop is sensitive to high temperatures, and aggressive moisture reduction methods threaten the seed embryo. Specialized seed drying technology applies gentle heating over an extended period to release the excess water without harming the seed.

Adjust the threshing parameters to the corn variety

Maize is more robust than other seeds, so the threshing mechanism must apply higher pressure with a faster rotation speed. Automatic corn seed processing equipment adapts to the plant material.

However, if you’re using a manual unit, you must set strict parameters to ensure that all grains are removed from the cob. Adjust the threshing gap between the plate and the groove to the correct size, and make sure not to overfeed the machine.

Separate the grains with specialized corn seed processing equipment

The kernels may be freed from the cob, but they still carry potential contaminants. Accurate cleaning is critical to maintaining the quality of breeding and foundation seeds.

A system of sieves separates the corn from soil and extraneous matter. The seeds, however, must similarly be sorted into different lots. Separation systems calibrate the kernels by size, weight, or density, while optical sorters pick out inconsistencies.

Coat the kernels to stave off insect raids

Retaining a high yield at the end of a complex process is already challenging. But seed producers must also contend with pest attacks.

Treat the kernels with a protective solution to keep rootworms and other corn insects away. The mixture typically contains fungicides such as carbendazim and thiram, but formulas vary per supplier.

Apply a homogeneous layer around the grains

Specialized coating equipment for seeds applies a uniform layer around each grain. Each kernel must be covered entirely in the protective film to prevent contamination later on during storage.

Different machines use a variety of techniques to perform the coating. While some technology dips the kernels in the solution, rotary systems pour it over the seeds.

Which corn seeds technology do you need?

Cart drying system for non-threshed corn and seeds

Simplify your seed drying process with a flexible system designed for ...

Vertical seed conditioning system for oil extraction

Ensure optimal oil yield and quality from oilseeds by employing a ve...

Corn seed sorting solution

Ensure precision in sorting and grading corn with optical and infrared technologies, enhancing pr...

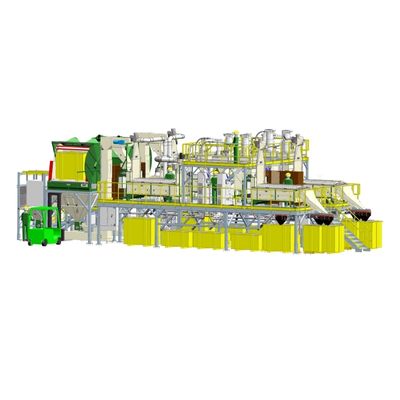

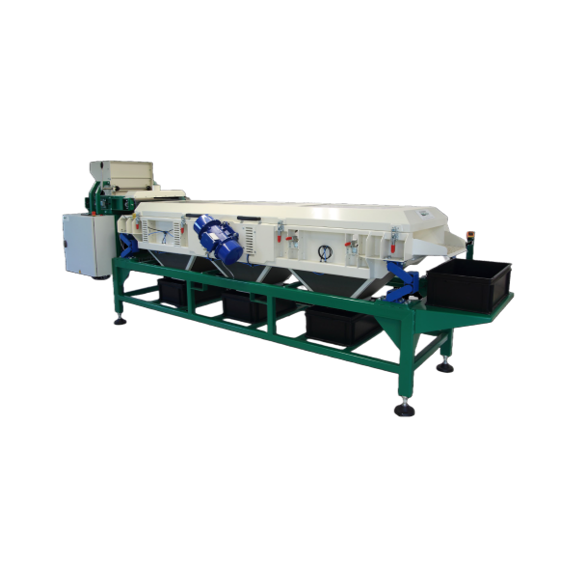

Automatic processing line for field crop seeds

The quality of field crops (ROW crops) is determined by their seeds. The br...

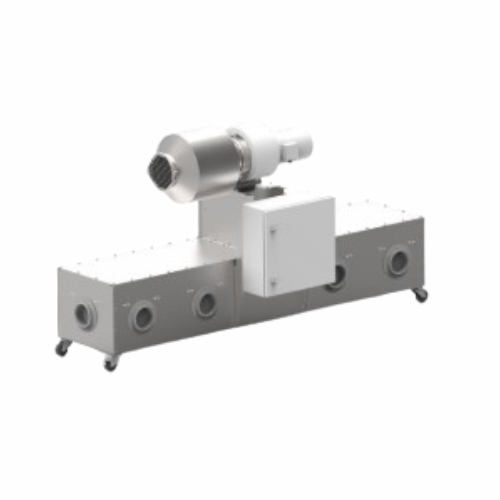

Fluidized bed drier/cooler for grains

Processed grains absorb moisture throughout the production line. Lowering that water ...

Color sorting machine for grains

Detecting impurities in processed grain becomes more challenging as the output increases. B...

Rotary Seed Pelleting Machine

When pelleting large batches of seeds like flower, vegetable, or agricultural types, it is imp...

Machine For Sizing Seeds

Seeds coming from the same plant might have different sizes and shapes. The germination percentage o...

Germination Cabinet For Commercial Growing

Each variety of seed has its optimum growing conditions including temperature, ...

Seed threshing machine

After threshing seeds from plant material, various cleaning steps still have to be done to ultimately ...

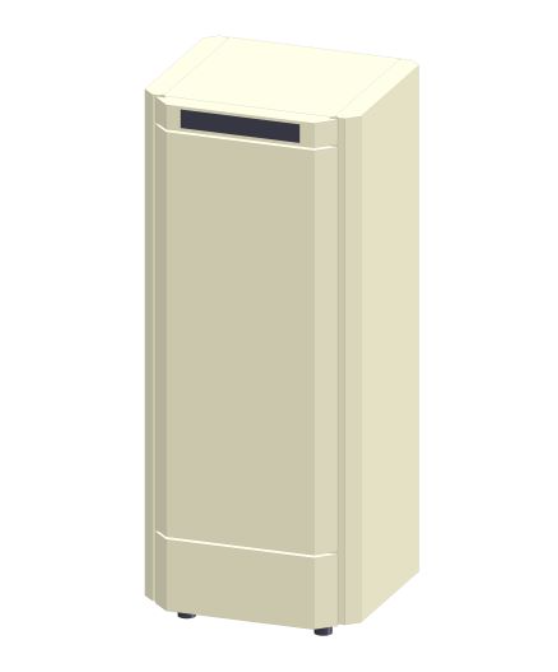

Seed storage cabinet

The proper storage of seeds is essential in conserving their vitality, and to maintain germination power...

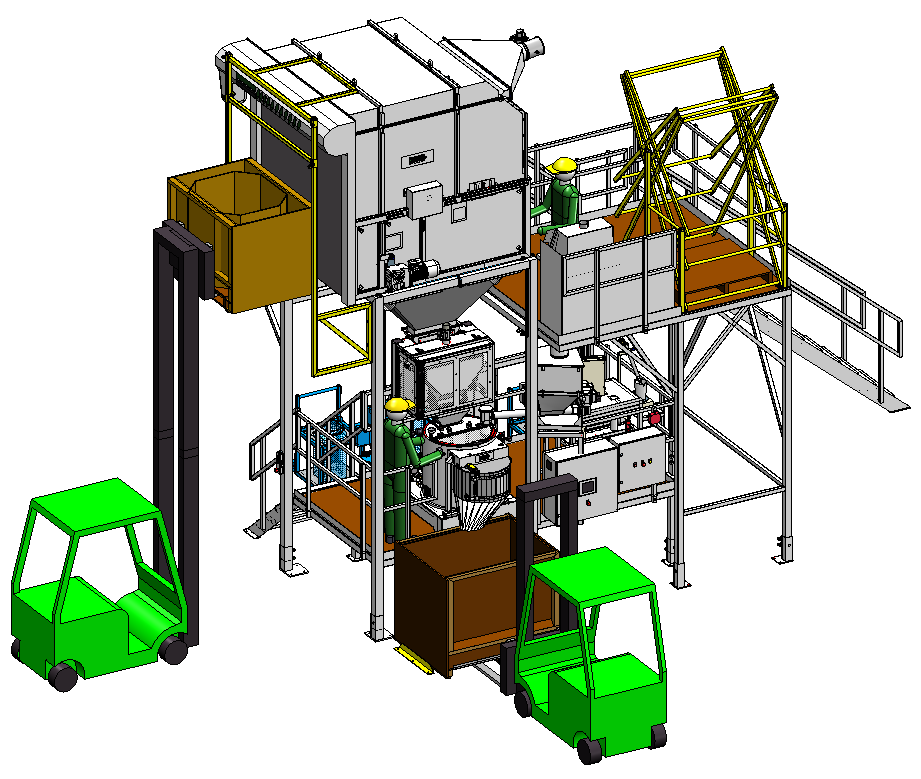

Open mouth bagging machine

If you are a manufacturer of fertilizers, bulk chemicals, sugar, seeds, or any grains it is likel...