Extraction of tomato seeds – take care of your red gold

Not all treasures are silver and gold… in the seed world, some are red too! Tomato seeds are one of the most valuable and expensive seeds out there. Just think that with only one seed, you can get from 20 up to even 90 tomatoes. In fact, the price varies from 10 cents to 1 euro per seed, if it is a special variety. Not surprisingly, then, breeding stations have some qualms about switching from manual extraction – which is considered the safest – to automatic extraction, as there may be a risk of damaging some of these precious seeds.

Switching from manual to automatic extraction, what can go wrong?

The tomato is cut in half in the manual process, and the seeds are gently extracted using a spoon. In an extraction machine, the beaters cut the tomato and remove the pulp from the fruit to extract the seeds. To do that, the beaters are usually sharp as knives and rotate at high speed to break the tomato into small pieces. Like a double-edged sword, the beaters will cut the tomato faster but at the same time could damage the seeds inside, which are very delicate.

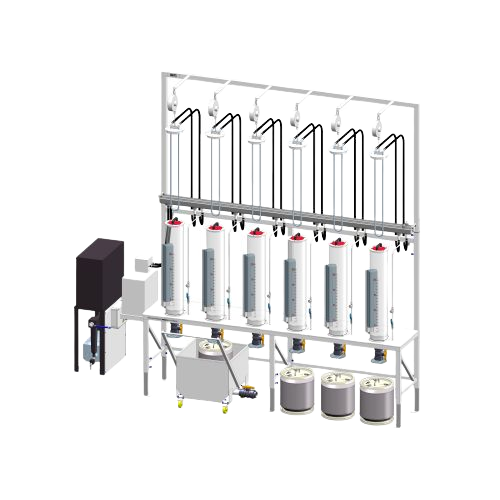

Another important factor to consider is cross-contamination. To create a new hybrid, breeding stations work with hundreds of samples coming from different tomato varieties every day. Therefore, each lot needs to be processed separately. If the extraction machine is not cleaned well, some seeds may be left behind, increasing the risk of mixing two different lots.

To go faster you must slow down

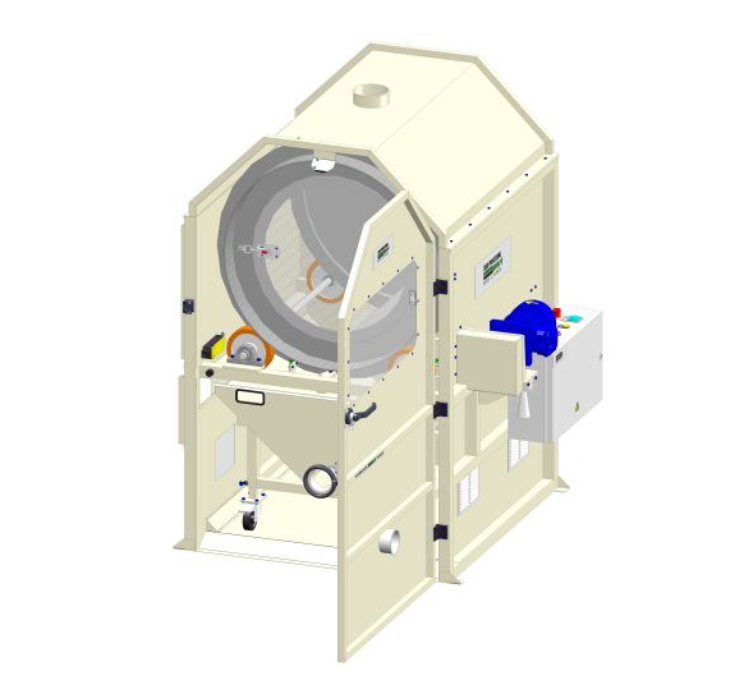

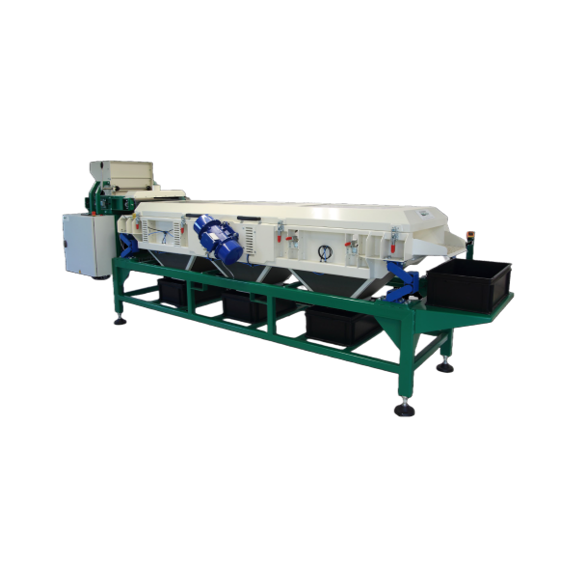

Seed Processing Holland has designed a machine to extract tomato seeds that helps breeding, production and manufacturing stations extract small lots of tomato seeds (± 10 – 100 tomatoes) avoiding any seed damage. “The tomato fruit is crushed by means of rotating beaters that are blunt and treat the seeds with the care they need. Then, the 5 mm screen separates the pulp from the seeds and the 1 mm screen collects the seeds as the juice passes through.” explains Willem van Dok, owner of SPH.

The crushing speed can be slowed down according to the tomato you are processing (cherry tomatoes, vine tomatoes). The machine has a built-in water nozzle system that works during and after the extraction process, minimizing residue formation (gel membrane around the seeds). “It’s also easy to access for thorough inspection” Willem continues. To make sure there’s no tomato seed left behind, you can open the machine for cleaning to ensure contamination is reduced to 0%. Get in touch if you are interested to learn more.