Making Ear Drops

Find innovative production technology for making eardrops and connect directly with world-leading specialists

The body produces earwax to protect the ear canal from microbial growth. But no one wants too much protection of this kind. Thankfully, simple solutions are available over the counter to medicate excess cerumen. Besides wax removal, eardrops and OTIC manufacturing provides an effective delivery technique to treat infections or administer anesthetic.

Select your eardrops process

Tell us about your production challenge

Manufacture earwax drops with glycerin to dissolve the blockage

Water-based preparations of earwax removal drops are designed to break down the cerumen. But the performance depends on the ingredients in the formulation.

Adding glycerin helps dissolve the earwax and facilitate its discharge. Baking soda, an alkali, reacts with the acidic cerumen and disintegrates the congestion in the ear canal. On the other hand, formulating ear drops with carbamide peroxide causes it to foam up when it comes into contact with the wax. This introduces oxygen and softens the buildup.

Apply ultrafiltration to purify the water of pathogens

Water purification is a critical step in the eardrops manufacturing process. After the preliminary chemical purification, the water undergoes ion-exchange treatment to remove undesired contaminants.

Force the water through a semipermeable membrane to eliminate any remaining bacteria and viruses. The ultrafiltered water is pumped through a sterile system to a distilling unit. Heat it until it reaches boiling point and evaporates, then condense it again by cooling.

Natural oils are alternative solvents to propylene glycol in anti-infective eardrops

In order to treat ear infections, eardrops products typically rely on propylene glycol as the principal solvent. But concerns about the ototoxic effects of this compound are fueling the search for alternative solvents.

Natural substances such as coconut oil, refined palm olein, and olive oil are emerging as primary substitutes. Unlike water-based preparations, oil-based formulations melt the cerumen and allow it to be released more quickly.

Increase the viscosity of eardrops with thickening agents

Eardrops manufacturing techniques involve a range of agents to modify the viscosity and pH of the final preparations. Higher viscosity increases the retention of the solution in the ear. A mix of suspending agents like cetyl alcohol and thickening agents like creatinine build up the resistance of the otherwise runny formulations.

Anti-bacterial eardrops attack the pathogens with slightly acidic solutions. The pH of the product is brought down to between 3-4 by adding acidic agents such as acetic acid, calcium carbonate, or citric acid.

Processing steps involved in eardrops making

Which eardrops technology do you need?

Agitator bead mill for API

To achieve precisely defined API properties and safe and reproducible production, rigorous implem...

Hygienic Cartoning Machine For Pharma and Health Products

When packing single or multiple vials, ampoules or devices int...

Laboratory liquid viewer for colored glass bottles

In the pharmaceutical industry, an inspection to detect any particulat...

Laboratory liquid viewer for varying light conditions

In the pharmaceutical industry, you must inspect liquids in vials o...

Laboratory liquid viewer for transparent glass bottles

Impurities like hair, fibers, or glass, sourced from the environme...

Pharmaceutical data management software

A typical pharmaceutical production handles numerous work flow activities like mana...

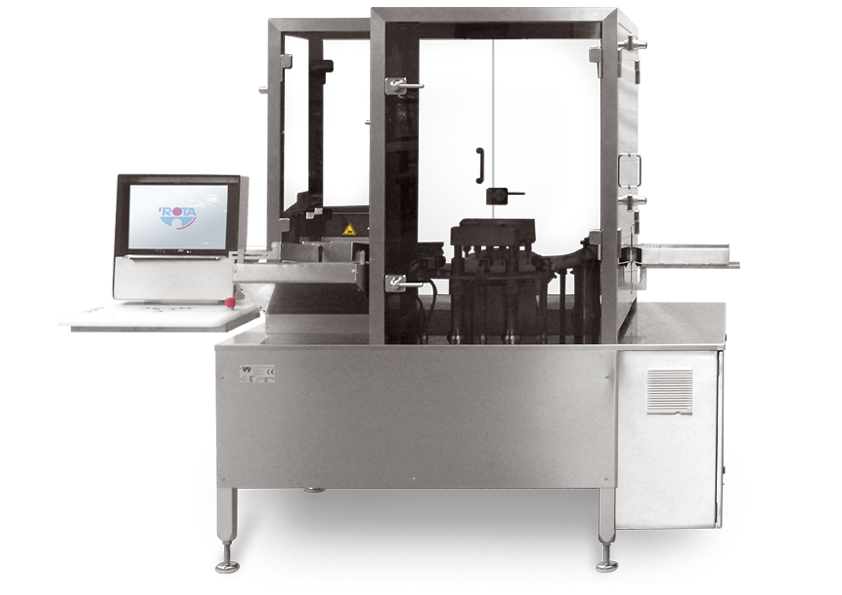

Flexible automatic inspection machine for ampoules, vials, cartridges

If you are looking to improve the efficiency of y...

Single-use temperature sensor

Biopharmaceutical manufacturers are increasingly making use of single-use temperature sensors ...

Pharmaceutical bottles inspection machine

For the visual inspection of small to medium batch-sizes of vials, ampoules or b...

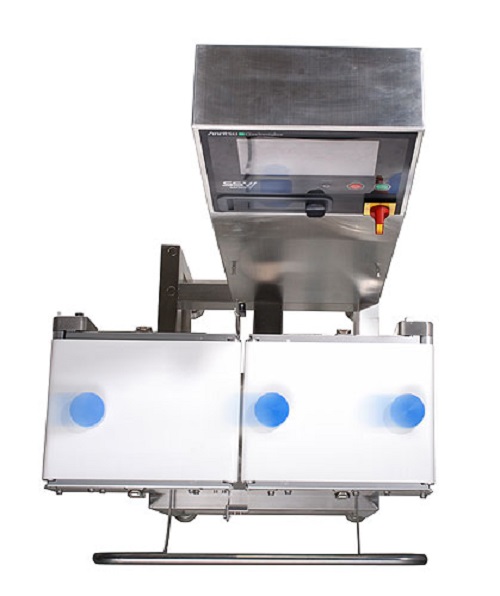

Small bottle checkweigher

Any small-diameter bottle, containing prescription medication or cosmetic applications, can be pro...

Versatile checkweigher

This Versatile checkweigher is equipped with a highly versatile strain gauge load cell. It is also sui...