Chocolate balls

Find innovative production technology for making chocolate balls and connect directly with world-leading specialists

Let's navigate the complex world of engineered-to-order production technology together. Whether you're building a new process or optimizing an existing line, our platform connects you directly to the experts who can help. Use our curated catalogue to dive straight into the technologies that match your production goals. We continuously map out how production technology from suppliers around the world can help solve real production challenges. If you find something interesting, we introduce you directly to the specialists who know how to implement it. With more than 600 trusted machine manufacturers and over 20.000 technical experts in our network, you’re never far from the answers you need.

Tell us about your production challenge

Which chocolate balls technology do you need?

Jelly and chocolate ball wrapping solution

Efficiently wrap jelly candies and chocolate balls with precision and high spee...

Rotationally symmetric product rolling machine

Achieve precision shaping of chocolate balls, candy drops, and more with ou...

Double twist wrapping solution for confectionery

Optimize packaging speed and precision with a machine designed to wrap di...

Chocolate moulding line for lentils, balls, and eggs

Achieve precision and efficiency in molding chocolate centers for le...

Lab-scale chocolate chip depositor

Enhance your R&D capabilities with precision depositing of chocolate masses, allowi...

Chocolate quality analysis instrument

Ensure the highest quality of your chocolate production by precisely measuring contra...

Chocolate temper measurement device

Ensure your chocolate maintains optimal temper by measuring and analyzing the chocolate...

Cooling simulator for chocolate production optimization

Optimize your chocolate cooling processes and refine production s...

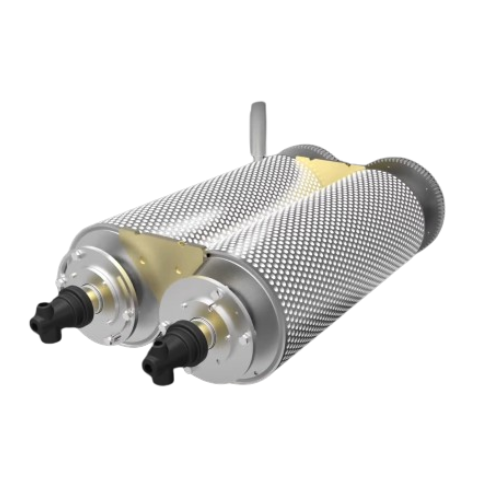

Laboratory roller for chocolate production

Easily switch between producing chocolate lentils, balls, and eggs with these f...

Laboratory cold-press chocolate shell maker

Enhance your R&D capabilities with a solution that enables precise cold-p...

Laboratory chocolate tempering solution

Achieve precise tempering of diverse chocolate and confectionery masses with optimi...

Small-scale chocolate enrober for laboratory use

Optimize small-scale chocolate production with a flexible enrober designe...

Flexible high-speed wrapper for confectionery products

Streamline your packaging process with a versatile machine designe...

Modular high-speed flow pack wrapper for preformed products

Eliminate packaging line bottlenecks with a versatile high-s...

Chocolate lentil, ball, and egg production system

Achieve consistent and precise shaping of chocolate lentils, balls, and...

Simultaneous chocolate dosing solution

Achieve high-precision chocolate and ganache filling in a single step with this effi...