Making Chamomile Oil

Find innovative production technology for making chamomile oil and connect directly with world-leading specialists

The humble chamomile flower holds a rich blend of compounds that soothe body and mind. A natural antidepressant and anti-inflammatory, chamomile oil found its way into the earliest pharmacopeia. As more of its properties were discovered, the oil became an elemental ingredient for a vast range of pharmaceutical and cosmetic recipes. Chamomile oil processing equipment developed at the same speed, offering manufacturers multiple production techniques to extract the liquid from the precious flower.

Tell us about your production challenge

Chamomile oil extraction peaks at 8 hours of steam distillation

The classic method for processing chamomile oil is steam distillation. The vapors from the steam machine attract the oils in the plant material as it rises through the distilling column. Pass the gaseous mixture through a condenser to turn it into separate oil and water liquids.

A longer distillation time yields a larger volume of oil, but the increase after 480 minutes is negligible.

Retain higher-quality chamomile oil compounds with UV extraction equipment

The healing properties of chamomile essential oil are down to its phenolic compounds, particularly flavonoids. However, higher extraction volumes do not necessarily mean a larger concentration of these precious metabolites.

A significant development in chamomile oil processing equipment is UV-Assisted Extraction (UAE). Immerse the flowers in an aqueous or ethanol solvent and apply UV technology to heat the blend to 60 °C. The technique preserves phenols better than conventional methods, although vitamin C content is lower.

Shield the volatile compounds from heat with supercritical CO2 extraction

An alternative method for processing chamomile oil is supercritical CO2 extraction. Pump pressurized carbon dioxide into the extractor vessel to release oil compounds from the organic matrix.

A system of pressure-reducing valves returns the fed CO2 into its gaseous state, discharging it into the chamber. However, supercritical extraction draws other materials from plants besides volatile oils. Pass the extracted substance through a separator to filter out the contaminants.

Use gentle drying systems to preserve the plant material

Both the German Chamomile and the Roman Chamomile, the two main varieties, contain their oils in the flowerhead. Chop the leaves and stalk with a de-stemmer and wash the flowers from soil residues or contaminants. Remove excess water from the material using a dewatering system before dehydrating the flowers.

The drying process brings down the moisture content of the flower relative to the environmental humidity. But chamomile is easily perishable, so gentle dehydrating methods such as vacuum drying are more suitable for making chamomile oil.

Processing steps involved in chamomile oil making

Which chamomile oil technology do you need?

Cosmetic cream filler

From thin liquid baby oils and perfumes to thicker lotions and creams for hair and skincare, cosmetic p...

Flower oil extraction machine

The production of “essential oils” has traditionally involved using heat and distillation to e...

Medicinal plant extraction machine

Traditional methods for extracting active compounds from medicinal plants or herbs use h...

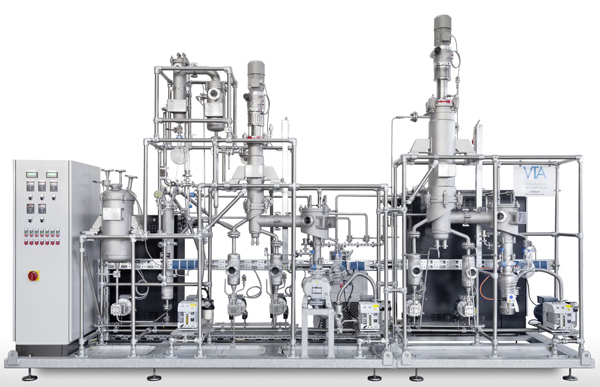

Extraction plant for natural ingredients

Bespoke extraction plants using the latest technology can improve your efficiency ...

Wiped film evaporator

With wiped film distillation, a substantial decrease of boiling temperature is obtained by reducing the...

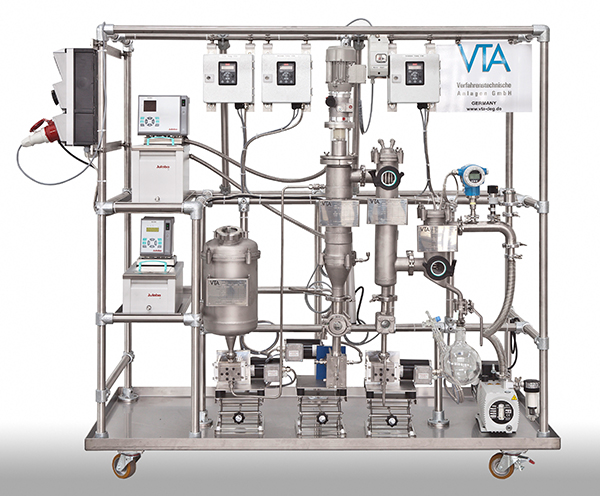

Pilot wiped film distiller

Generate scalable data and results during the pilot tests with wiped film distillation, distill ...

Pilot short path distiller

Generate scalable data and results during the pilot tests with short path distillation, distill o...

Laboratory short path distiller

Get to reliable conclusions for the separation of high-boiling and heat-sensitive products u...

Horizontal thin film evaporators

Horizontal thin film evaporators can increase the residence time of the product and achieve...