Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on growing the volume of your production line. When expending your canned coffee business, having separate machines for each step can be time consuming.

Filling and seaming cans or jars with the same machine

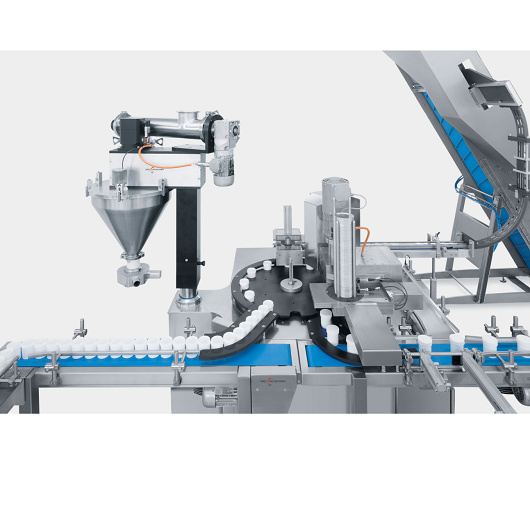

The Matic 101 CFCGP by Swiss Can Machinery is a can and jar filling and closing machine for powdered products. The process of filling and closing the can or jar starts of by placing the jar on the conveyor belt, that will feed the filled vessel onto a turning table. The filling and dosing is done with a precise servo drive, the produce is fed via a horizontal auger with level control and a vibrator makes sure the powdered material in the cans doesn’t stick to anything else. Each can or jar is weighted separately and automatically before it is capped or seamed.

The jars are moved onto a screw capping device (caps are destacked at their own station) and discharged if not capped correctly. Cans move to the seaming station, where a spindle applies pressure so that the seaming rollers can seam the can in separate stages. The can or jar diameter must be between 50 and 100 mm.

Benefits

- Variable can sizes

- Deduster integrated at filling outlet and on base plate

- Speed of seaming rollers independently adjustable