Making Raw Pet Food

Find innovative production technology for making raw pet food and connect directly with world-leading specialists

Many pet owners consider themselves parents of furry babies, meaning they consider their pets as family rather than companions. Consequently, pet owners are getting more concerned about their pets’ health and actively demanding a healthy diet. To respond to this market demand, there is a rise in raw pet food production, in which ingredients stay in a more natural state refraining from ultra-processing them and avoiding using preservatives and synthetic additives.

Select your raw pet food process

Tell us about your production challenge

Raw pet food production processes food without ultra-processing it

Ultra-processed dry pet food such as kibbles has preservatives, additives, and fillers to enhance shelf-life and compensate for the nutritional value lost in the different stages of the transformation process. Even though their nutritional promise is fulfilled and balanced, some customers have concerns about ultra-processed food especially if their pets have health issues such as allergies or gut problems.

Raw pet food manufacturing aims to provide food in its most natural state possible to preserve its nutritional value. Without ultra-processing the ingredients, it uses a short process to prepare them for consumption. To start the process, you need to verify if the meat and animal by-products you will use are fresh or frozen. If frozen, chop the ingredients before passing them through the grinder and mixing it with vegetables, fruits, and dairy to make a nutritionally balanced patty. Finally, freeze the mix to preserve it.

Challenges and solutions to overcome the risks of microbial contamination in raw pet food

Raw food, especially meat, is susceptible to pathogenic bacteria contamination at any stage of the supply chain. Therefore, you need to keep the process under low temperatures, and at the end, make a flash freezing to preserve nutritional value, freshness, and taste. Following the manufacturing guidelines, keeping a sterilized environment is essential to avoid contamination with hazardous microorganisms.

Handling raw food has its challenges, yet there are some popular sterilization solutions that you can use to overcome safety risks. One of them is HPP or high-pressure processing. This is an extra process in which the patty is submitted to a pressure of 87.000 psi for about 3 minutes inside a chamber with water. With this cold pasteurization process, most of the bacteria are killed. The other known method is HACCP, or hazard analysis and critical control points. A series of safety standards, analyses, and tests to ensure safety from hazards at every step of food processing.

Processing steps involved in raw pet food making

Which raw pet food technology do you need?

Rotary drum sifter for pellets and chunks

Achieve precise particle separation and minimize product loss with a rotary drum...

Manure treatment system for livestock breeding

Optimize waste-to-value processes with advanced systems designed to efficie...

Machine for packing canned pet food

Most packaging applications require different types of packaging machines, some need wr...

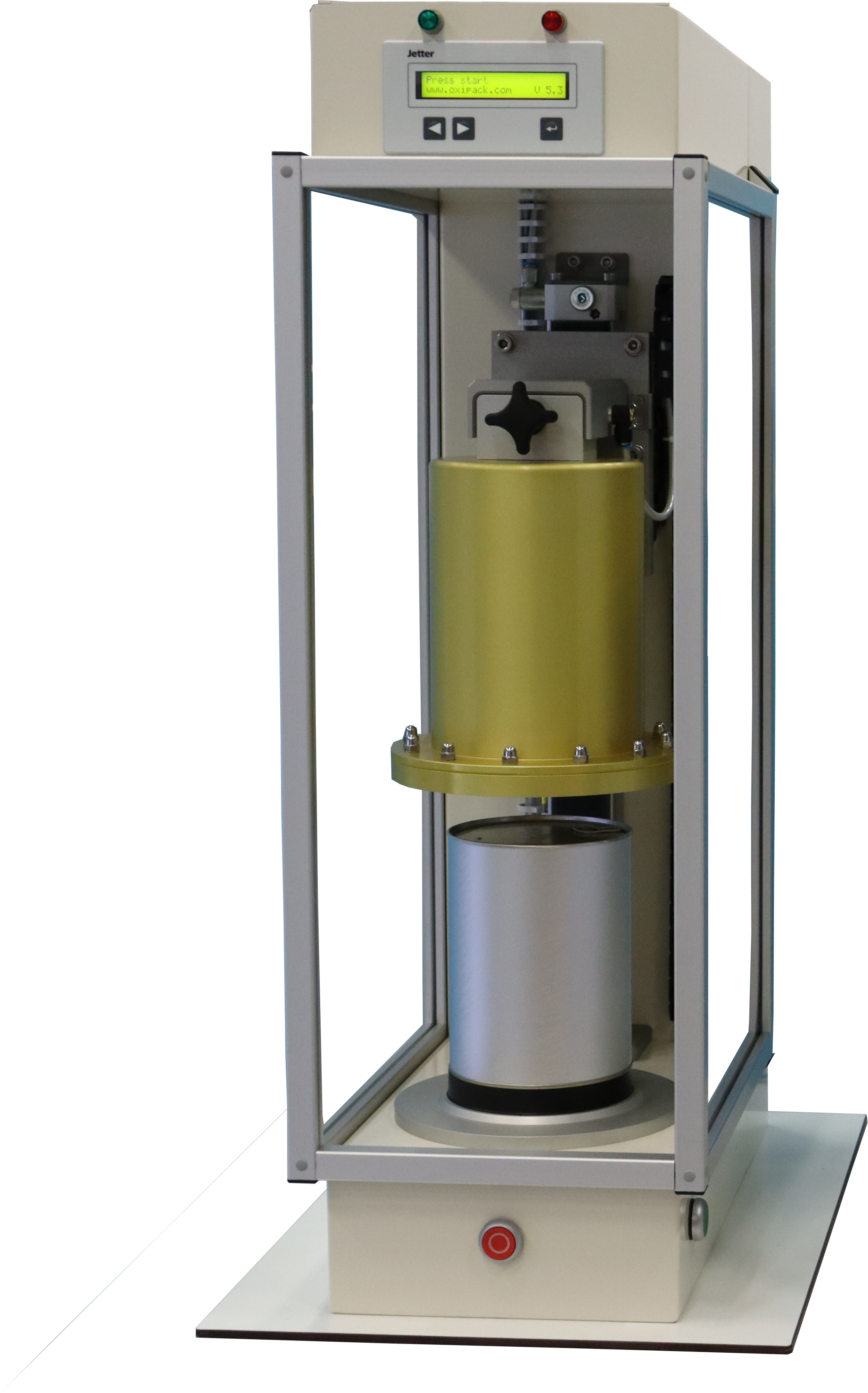

Can leak tester

Every canned pet food producer knows that their product should avoid the growth of microorganisms that could s...

High speed carton closing machine

Choosing a carton closing machine becomes a significant consideration when the closing of...

Horizontal cartoner for food products

Depending on the primary product packages, food products like confectionery (biscuits...

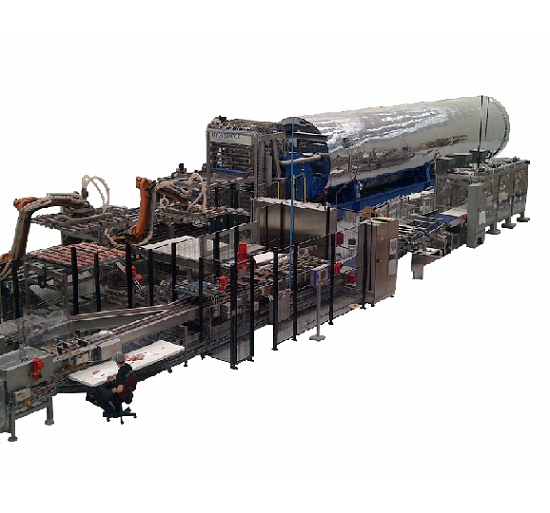

Continuous sterilizer for pet food

Sterilization is a critical operation in the manufacturing of wet pet foods. An importan...

Display tray cartoner machine

Packaging products usually require a great deal of flexibility to comply with demand from mark...

Vertical cartoning machine

In the food industry, a large number of bulk products like for example pasta, need to be packed i...

Continuous dryer machine

Traditional drying methods in the pet food, aquafeed, and extruded food industry can be the most ene...

Hygienic belt dryer

A belt dryer typically applies the product through an infeed chamber onto a perforated horizontal belt, w...

Air dehumidifier for bulk products

When your product or process is sensitive to humidity, using an air dehumidifier may res...

Reclaim crusher

Waste products and rejected materials are inevitably generated from any gypsum products manufacturing process....