Making Foam Kisses

Find innovative production technology for making foam kisses and connect directly with world-leading specialists

Foam kisses are known by different names, but their unique texture is unmistakable no matter what you call them. The chocolate mound with a frothy filling is an all-time favorite, but creating that crispy-fluffy contrast is no longer a job of approximation. Specialized foam kisses machines range from mixers to enrobers. But the magic of the delightful confection happens with aeration technology.

Tell us about your production challenge

Balance the disaccharides to obtain the right texture

The base ingredients for the batter are sugar and corn syrup. Although sugar and corn syrup are both sweeteners, they behave differently in a mixture, so the balance between the two defines texture and taste.

Sugar is sweeter but tends to crystallize, making the mixture more brittle. Corn syrup is not as sweet and forms a somewhat gooey texture.

Paddles in horizontal mixers combine the compound into the confectionery mass

Prepare the batter by compounding the main ingredients with egg white and a thickening agent such as gelatin. This process combines the elements into the right formula before it is pumped into the mixing systems.

In the mixer, the formula is amalgamated into a homogeneous mixture. Use a horizontal mixing machine to drive the foam kisses mixture from side to side, developing it uniformly.

Aerators are the crucial foam kisses machines

The critical component in foam kisses production is air. The pockets of oxygen modify the bulk density of the mixture.

Aerators are specialized machines that pump air cells into the mass, incorporating them through precise mixing. Aeration solutions are programmed to reproduce the same foam density across different batches. A high density forms firmer consistencies, while lighter foam densities develop softer ones.

Heat the mix gently to remove extra water content

Excess moisture in the mixed batter degrades the foam kisses. Apart from dissolving the microstructure of the formula, water promotes microbial growth and shortens the shelf-life of the final product.

Baking in an industrial oven evaporates extra moisture from the confectionery mass, but overheating the mixture stiffens it. Protect the gelatin from denaturing by applying mild heating below 40°C.

Deposit precise mass quantity using dosing systems

The traditional recipes of schokokuss build the sweet treat on a wafer base. Pump the final mix into the assembly section, where a depositor system drops a precise amount of the batter onto the wafers.

Depositing machines for foam kisses typically incorporate a weighing and dosing feature to ensure homogeneous servings and reduce wastage.

Form the chocolate shell with special enrobing machines for foam kisses

The unique pleasure of foam kisses is the contrasting texture between the thin crisp of the chocolate shell and the fluffy interior.

Convey the deposited mounds through an enrober machine to coat them in chocolate. The main challenge during the enrobing process is covering the entire surface with a uniform layer of molten chocolate. Enrobers use a system of blowers and agitators to remove the excess coating and recover the extra chocolate for more enrobing.

Bring the temperature down to set the foam kisses without deforming them

The outer shell is made from molten chocolate. Some enrobers integrate a tempering system to give the chocolate a smooth finish.

But once enrobed, your new foam kisses must cool rapidly to harden the chocolate into shape. Pass the trays carrying the treats through a cooling tunnel to lower the temperature at high speed.

Processing steps involved in foam kisses making

Which foam kisses technology do you need?

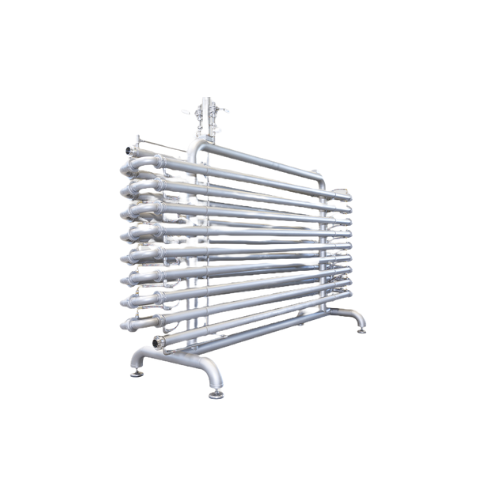

Static cooler for jelly and foam manufacturing

Ensure the integrity of your confectionery with a cooling system designed f...

Large capacity confectionary mixer

The foaming process determines the quality of various confectionery products, from marsh...

Compact & pumpable food media mixer

The process of mixing ingredients for confectionery products like marshmallows and meri...

Mixing system for batter and cream

When making a cake, the proper mixing of liquid batter is critical to ensuring it looks ...

Horizontal cooling tunnels for chocolate moulds

The perfect tunnel for semi-automatic production lines.